Method for preparing high-corrosion-resistant hot spray coatings for magnesium alloy surfaces

A magnesium alloy and thermal spraying technology, which is applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of magnesium alloy substrate protection and easy corrosion, and achieve simple construction, improved corrosion resistance, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

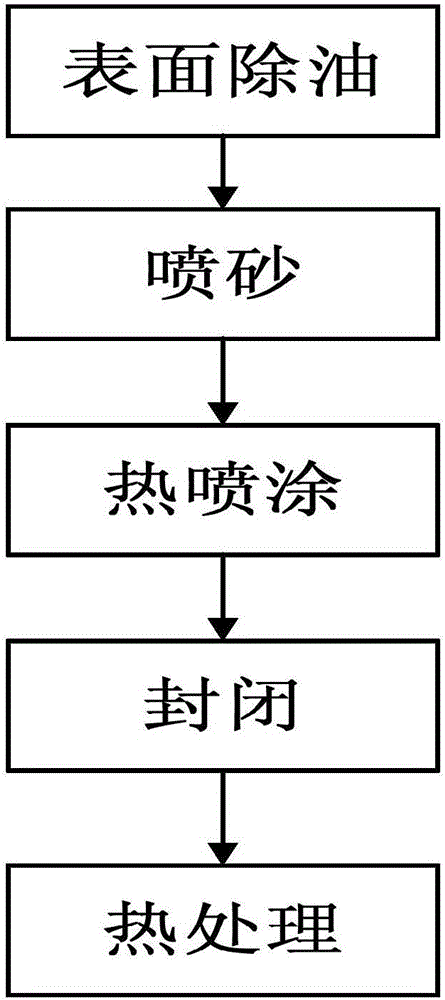

[0038] Such as figure 1 Shown, a kind of preparation method of the high corrosion resistance thermal spraying coating on magnesium alloy surface, the step of this method comprises:

[0039] (1) Carry out degreasing treatment on the surface of the magnesium alloy material, which can be washed or wiped with gasoline or ethanol;

[0040] (2) Sandblasting the surface of the magnesium alloy material after the degreasing treatment in step (1), the sandblasting grains are corundum, and the particle size is 80 to 120 meshes; the sandblasting air pressure is controlled in the range of 0.2Mpa to 0.5Mpa;

[0041] (3) adopt the method for electric arc thermal spraying to carry out the thermal spraying preparation of metal coating on the magnesium alloy material surface that step (2) obtains;

[0042] The parameters during thermal spraying are: spraying voltage is 30-35V, spraying current is 90-110A, spraying air pressure is 0.7-0.9MPa, spraying distance is 150-350mm, spraying air source ...

Embodiment 1

[0056] A method for preparing a high-corrosion-resistant thermal spray coating on the surface of a magnesium alloy, the steps of the method comprising:

[0057] (1) Degreasing the surface of the magnesium alloy material, and wiping it with gasoline;

[0058] (2) Sandblasting the surface of the magnesium alloy material after the degreasing treatment in step (1), the sandblasting grains are corundum, and the particle size is 120 mesh; the sandblasting air pressure is controlled in the range of 0.3Mpa~0.5Mpa;

[0059] (3) adopt the method for electric arc thermal spraying to carry out the thermal spraying preparation of metal coating on the magnesium alloy material surface that step (2) obtains;

[0060] The parameters during the thermal spraying are: the spraying voltage is 32V, the spraying current is 90A, the spraying air pressure is 0.8MPa, the spraying distance is 250mm, and the spraying gas source is compressed air;

[0061] The raw material adopted in the metal coating is...

Embodiment 2

[0072] A method for preparing a high-corrosion-resistant thermal spray coating on the surface of a magnesium alloy, the steps of the method comprising:

[0073] (1) Degreasing the surface of the magnesium alloy material, and wiping it with gasoline;

[0074] (2) Sandblasting the surface of the magnesium alloy material after the degreasing treatment in step (1), the sandblasting grains are corundum, and the particle size is 100 mesh; the sandblasting air pressure is controlled in the range of 0.2Mpa~0.3Mpa;

[0075] (3) adopt the method for electric arc thermal spraying to carry out the thermal spraying preparation of metal coating on the magnesium alloy material surface that step (2) obtains;

[0076] The parameters during the thermal spraying are: the spraying voltage is 35V, the spraying current is 100A, the spraying air pressure is 0.9MPa, the spraying distance is 300mm, and the spraying gas source is compressed air;

[0077] The raw material used in the metal coating is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com