Immobilization method of xylanase and immobilized xylanase

A xylanase and modification technology, applied in the field of enzyme engineering, can solve the problems of high price of enzymes, limited application, difficult recovery, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Weigh APTES modified Fe 3 o 4 @SiO 2 Nanoparticles 1.0057g was placed in 100mL (pH=5.5) of acetic acid-sodium acetate buffer solution, added 4% (v / v) 19.05mL concentration of 25wt% glutaraldehyde solution, mechanically stirred in a water bath at 25°C, 180rpm After stirring for 4 hours, APTES modified Fe 3 o 4 / SiO 2 Nanoparticles loaded with glutaraldehyde;

[0054] Add 0.1295 g of xylanase dissolved in acetic acid-sodium acetate buffer solution, and mechanically stir at 180 rpm for 3 hours to obtain immobilized xylanase;

[0055] Magnetically separate, wash with acetic acid-sodium acetate buffer solution 3 to 4 times, and finally use acetic acid-sodium acetate buffer solution to make up to 100mL; put it in the refrigerator for later use.

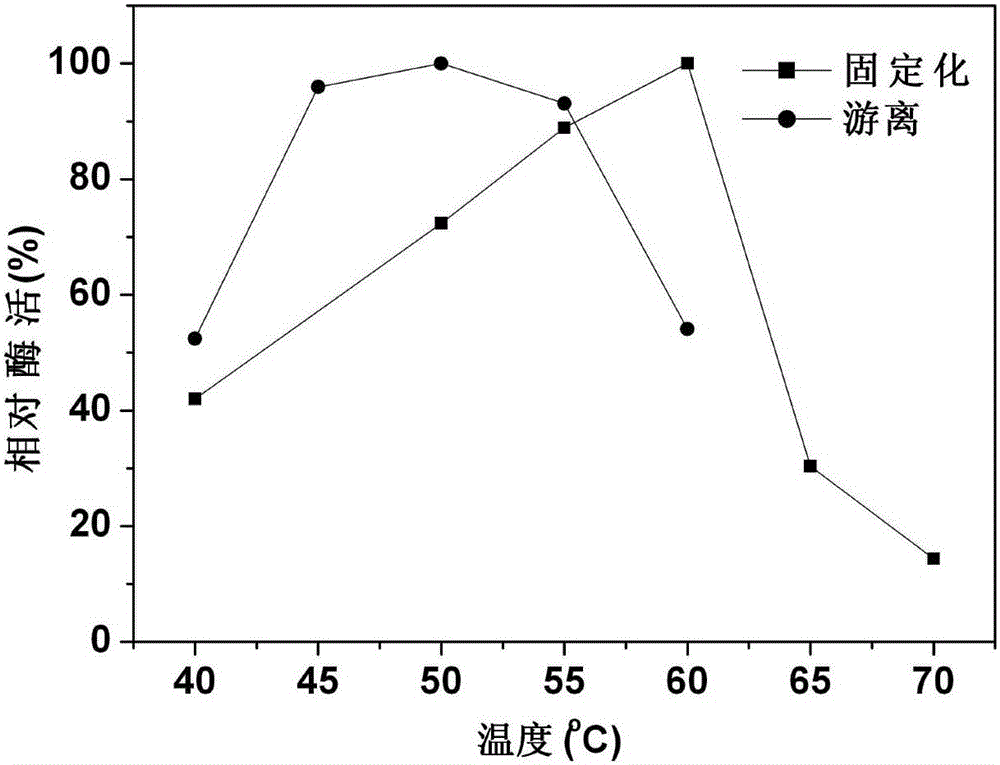

[0056]Test the impact of different influencing factors on the enzymatic activity of the immobilized xylanase obtained in the present embodiment and the free state xylanase:

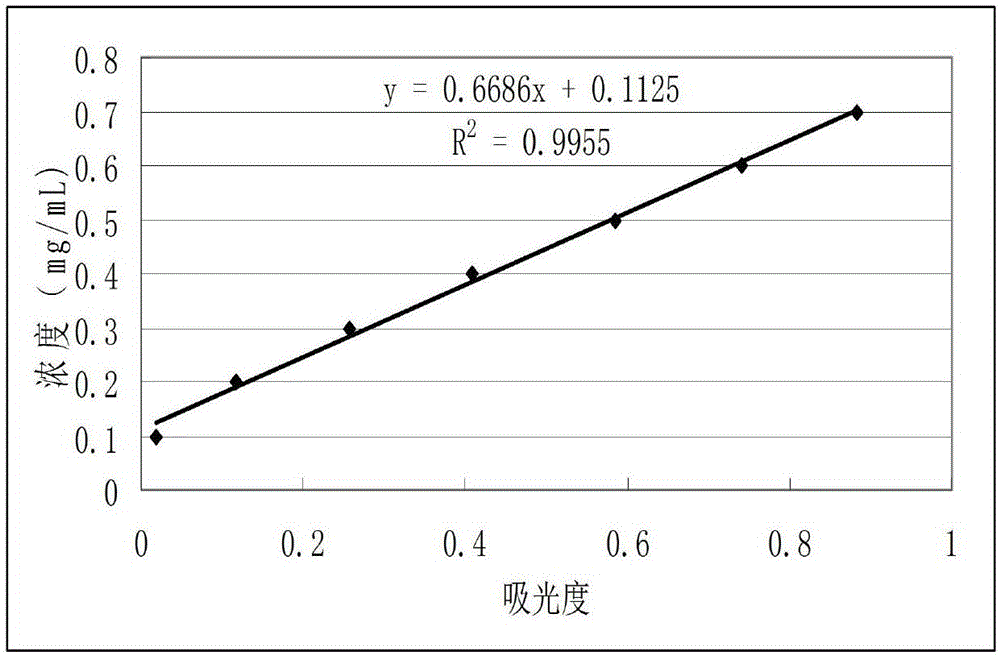

[0057] 1. Preparation of solutions and samples

[...

Embodiment 2

[0107] Weigh APTES modified Fe 3 o 4 @SiO 2 Nanoparticle 5g is placed in the acetic acid-sodium acetate buffer solution of 150mL (pH=5.5), add 4% (v / v) 95mL concentration and be 25wt% glutaraldehyde solution, carry out mechanical stirring in 25 ℃ of water baths, 180rpm stirs 4 hours, get APTES modified Fe 3 o 4 / SiO 2 Nanoparticles loaded with glutaraldehyde;

[0108] Add 0.65 g of xylanase dissolved in acetic acid-sodium acetate buffer solution, and mechanically stir at 180 rpm for 3 hours to obtain immobilized xylanase;

[0109] Magnetically separate, wash with acetic acid-sodium acetate buffer solution 3 to 4 times, and finally use acetic acid-sodium acetate buffer solution to make up to 100mL; put it in the refrigerator for later use.

[0110] The immobilized xylanase obtained in the present embodiment is tested for performance using the experimental means in Example 1, and the results are as follows:

[0111] 60°C is the best pretreatment temperature for immobilize...

Embodiment 3

[0118] Weigh APTES modified Fe 3 o 4 @SiO 2 Nanoparticle 15g is placed in the acetic acid-sodium acetate buffer solution of 500mL (pH=5.5), add 4% (v / v) 285mL concentration and be 25wt% glutaraldehyde solution, carry out mechanical stirring in 25 ℃ of water baths, 180rpm stirs 4 hours, get APTES modified Fe 3 o 4 / SiO 2 Nanoparticles loaded with glutaraldehyde;

[0119] Add 1.95 g of xylanase dissolved in acetic acid-sodium acetate buffer solution, and mechanically stir at 180 rpm for 3 hours to obtain immobilized xylanase;

[0120] Magnetically separate, wash with acetic acid-sodium acetate buffer solution 3 to 4 times, and finally use acetic acid-sodium acetate buffer solution to make up to 300mL; put it in the refrigerator for later use.

[0121] The immobilized xylanase obtained in the present embodiment is tested for performance using the experimental means in Example 1, and the results are as follows:

[0122] 60°C is the best pretreatment temperature for immobili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com