Sludge pyrolysis method adopting biomass adding

A biomass and sludge technology, applied in the field of sludge pyrolysis with biomass addition, can solve the problems of unproduct utilization and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

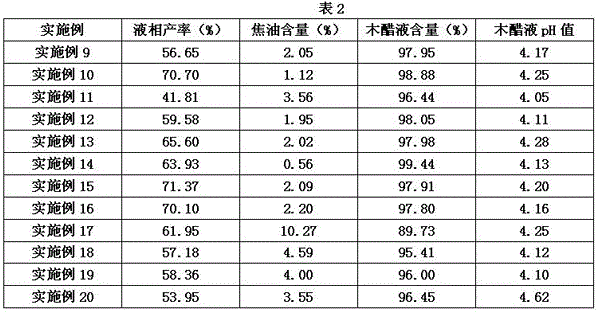

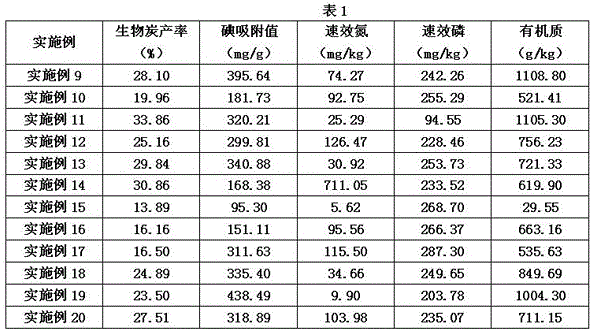

Examples

Embodiment 1

[0015] Embodiment 1, the sludge pyrolysis method of adding biomass is carried out according to the following steps: in the first step, the biomass is first pulverized into powder, and then the biomass, sludge and catalyst are mixed according to the ratio of 0.25 to 4:1:0.02 to The mass ratio of 0.08 is mixed evenly to obtain a mixture; the second step is to place the mixture in a reaction kettle, pass nitrogen gas as a protective gas, and heat up to a pyrolysis temperature of 300°C to 700°C according to a certain heating program for pyrolysis. The time is 30min to 180min. After pyrolysis, solid phase products, liquid phase products and gas phase products are obtained respectively. The liquid phase products enter the liquid phase product collector, and the gas phase products are collected in the air bag; the third step is to obtain the After the solid phase product, stop heating and continue to pass nitrogen into the reactor to cool to room temperature, grind the solid phase pro...

Embodiment 2

[0016] Embodiment 2, the sludge pyrolysis method of adding biomass is carried out according to the following steps: in the first step, the biomass is first pulverized into powder, and then the biomass, sludge and catalyst are mixed in a ratio of 0.25 or 4:1:0.02 or The mass ratio of 0.08 is mixed evenly to obtain a mixture; the second step is to place the mixture in a reaction kettle, pass nitrogen gas as a protective gas, and heat up to a pyrolysis temperature of 300°C or 700°C according to a certain heating program for pyrolysis. The time is 30min or 180min. After pyrolysis, solid phase products, liquid phase products and gas phase products are obtained respectively. The liquid phase products enter the liquid phase product collector, and the gas phase products are collected in the air bag; the third step is to obtain the After the solid phase product, stop heating and continue to pass nitrogen into the reactor to cool to room temperature, grind the solid phase product finely ...

Embodiment 3

[0017] Embodiment 3, as an optimization of the above embodiments, the biomass is more than one of peanut shells, sawdust, corn stalks, corn cobs and rice straw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com