Concave internal and external dual-heating efficient reaction kettle for pyrolysis of waste tyre, waste plastics and domestic electronic waste

A technology of electronic waste and reactor, which is applied in the direction of indirect heating dry distillation, special form dry distillation, educts, etc., can solve the problems of limited pyrolysis efficiency and limited heat acceptance, so as to increase the heating area, improve production efficiency, and accelerate heating. solution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described in conjunction with the following examples.

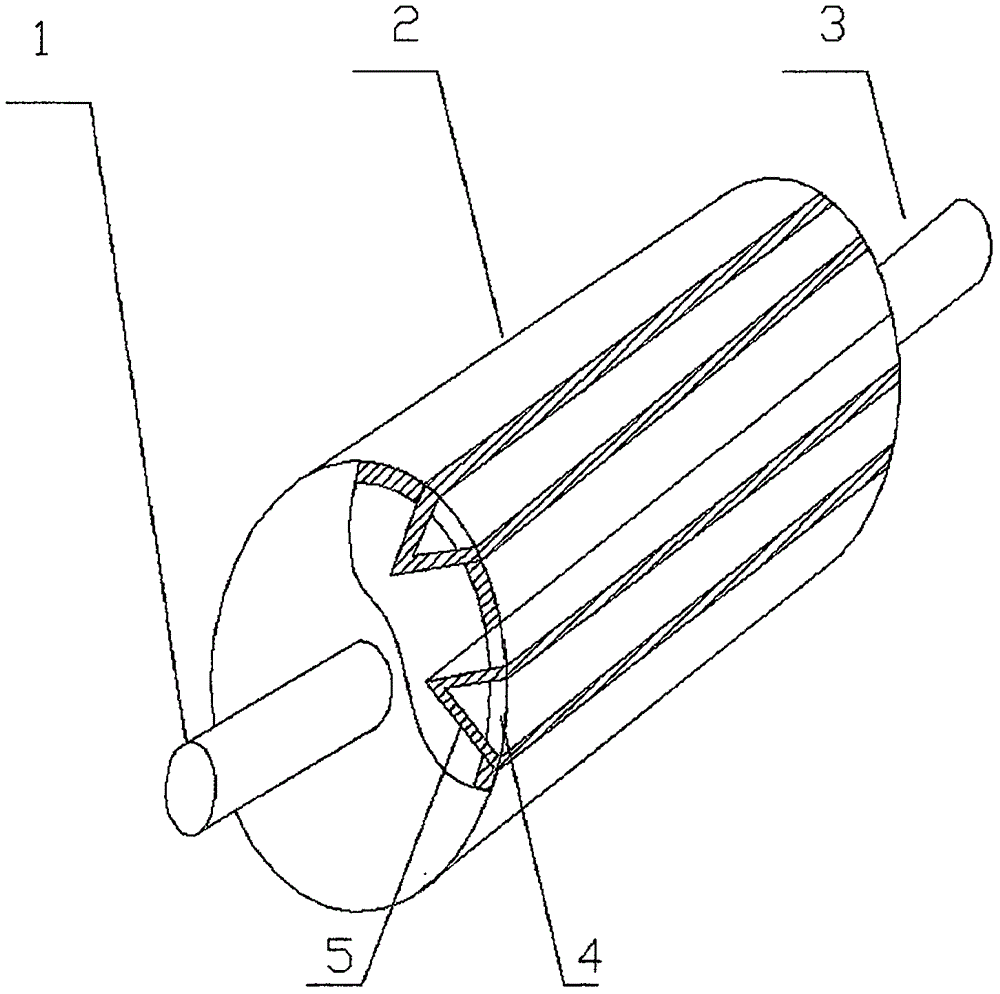

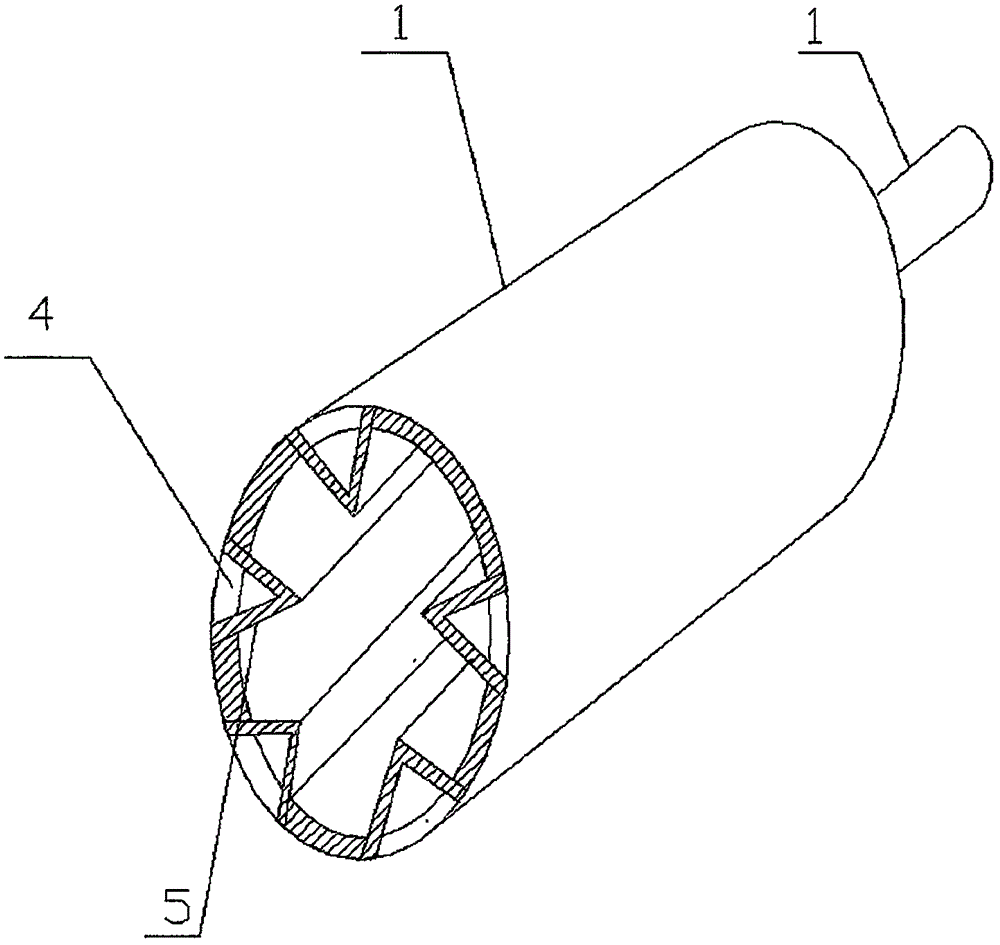

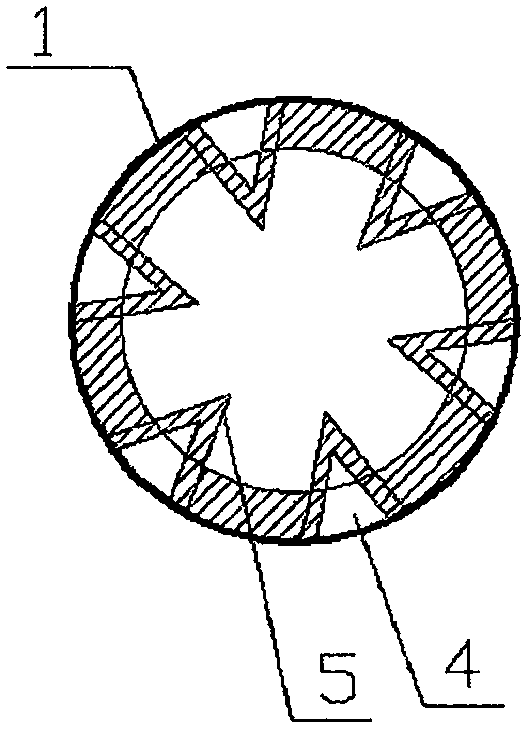

[0016] The specific embodiment of the present invention is a groove-type high-efficiency reactor with internal and external double heating for the pyrolysis of waste tires, waste plastics, and domestic electronic waste. , wherein, there are more than 2 openings on the circumference of the reactor body, the top corner of the groove splint extends into the reactor body, and the two sides of the opening are firmly welded to the opening of the reactor body; the feed pipe is welded at one end of the reactor body The baffle plate; the gas outlet and slag discharge pipe is welded on the other end baffle plate of the reactor body.

[0017] The groove type high-efficiency reactor with internal and external heating for the pyrolysis of waste tires, waste plastics, and domestic electronic waste is described. The groove plate is formed by folding one steel plate or combining and welding two ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com