Electron beam radiation curing coating for metal heavy anti-corrosion

A technology of electron beam radiation and curing coatings, which is applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as poor anti-corrosion performance and mechanical properties, incomplete deep curing of cured coatings, weak adhesion between coatings and substrates, etc. Achieve the effects of high curing efficiency, strong anti-corrosion ability and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

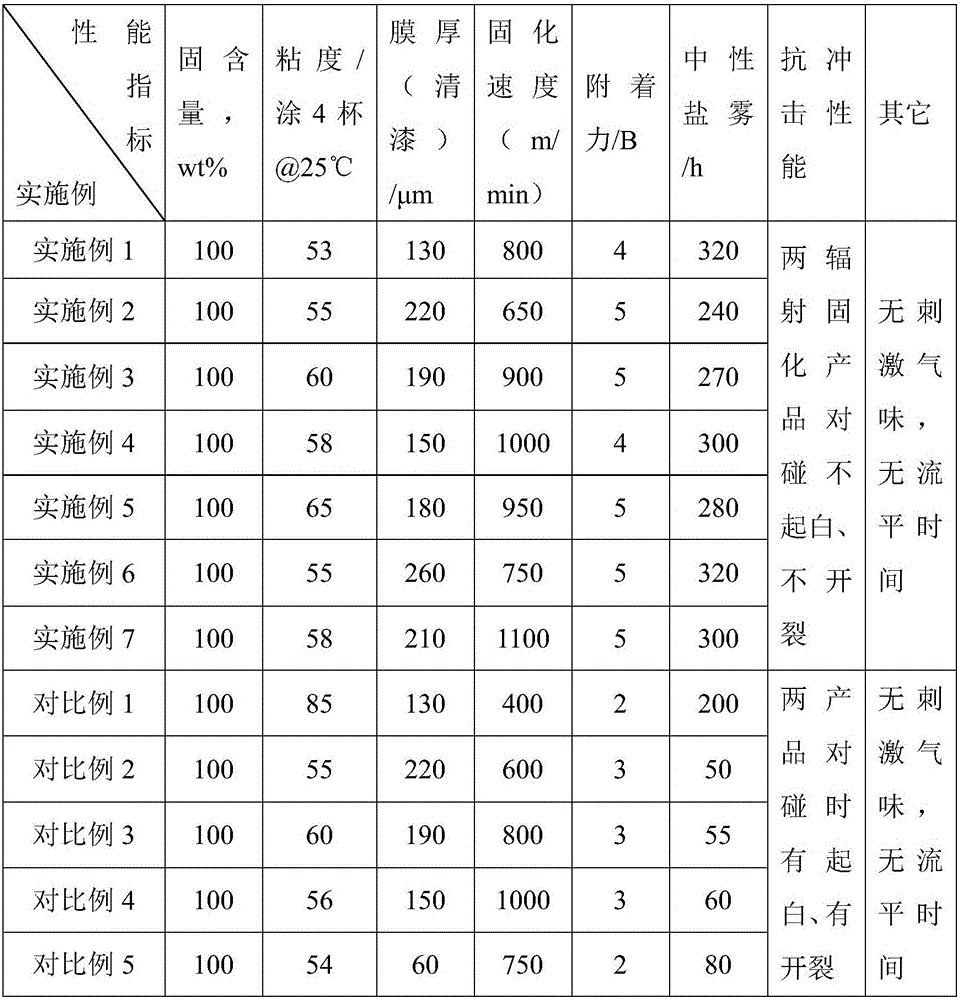

Embodiment 1

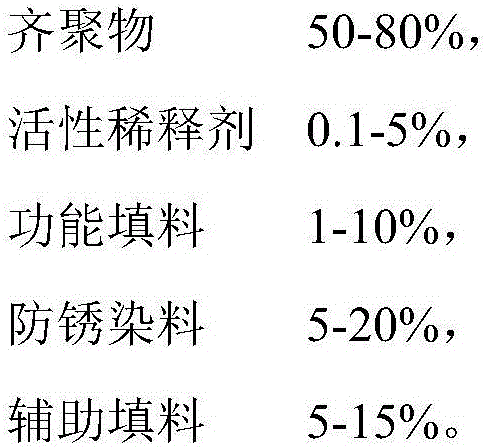

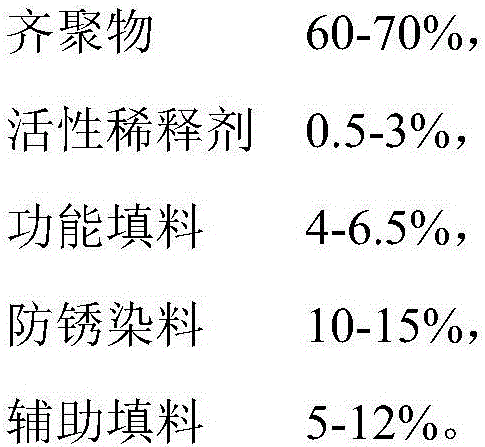

[0024] An electron beam radiation curing coating for heavy metal anticorrosion, each component of which is proportioned according to the following mass fractions:

[0025] Epoxy resin oligomer 40g

[0026] Silicone modified epoxy resin oligomer 20g

[0027] Alkoxyhexanediol diacrylate 5g

[0028] Carbon black 10g

[0029] Mica iron oxide 5g

[0031] Nano alumina 10g

Embodiment 2

[0033] An electron beam radiation curing coating for heavy metal anticorrosion, each component of which is proportioned according to the following mass fractions:

[0035] Silicone modified epoxy resin oligomer 35g

[0036] Tricyclodecane dimethanol diacrylate 2g

[0037] Tris(2-hydroxyethyl)isocyanurate triacrylate 1g

[0038] Carbon black 0.5g

[0039] Polyaniline 0.5g

[0041] Aluminum tripolyphosphate 7g

[0042] Fumed silica 4g

[0043] Nano alumina 4g

Embodiment 3

[0046] An electron beam radiation curing coating for heavy metal anticorrosion, each component of which is proportioned according to the following mass fractions:

[0047] Acrylic resin oligomer 15g

[0048] Silicone modified epoxy resin oligomer 25g

[0049] Silicone modified acrylate 30g

[0050] Alkoxyhexanediol diacrylate 0.2g

[0051] Tris(2-hydroxyethyl)isocyanurate triacrylate 0.2g

[0052] Dipentaerythritol hexaacrylate 0.1g

[0053] Graphene 4.5g

[0054] ST anti-rust powder 10g

[0055] Nano silicate 5g

[0056] Fumed white carbon black 10g

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com