Production method of high-density ammonium metavanadate

A technology of ammonium metavanadate and its production method, which is applied in the field of metallurgical chemistry of vanadium, can solve problems such as low product quality, difficulty in mixing uniformly, large vanadium oxide dust, etc., and achieve the goals of improving crystallization characteristics, changing solubility, and improving surface tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 46g sodium hydroxide, 100gV 2 o 5 Add the powder into water in turn, stir to dissolve, filter the insoluble matter, and set the volume to 1000ml to obtain a clear sodium metavanadate solution, pH 9, containing V 1.05mol / L.

[0039] Add 1g of PAM with a molecular weight of 1 million and stir until completely dissolved;

[0040] The solution was heated up to 45°C, 120g of ammonium chloride was added, and the temperature was kept stirring for 2h;

[0041] Cool down to 25°C and continue stirring for 1h;

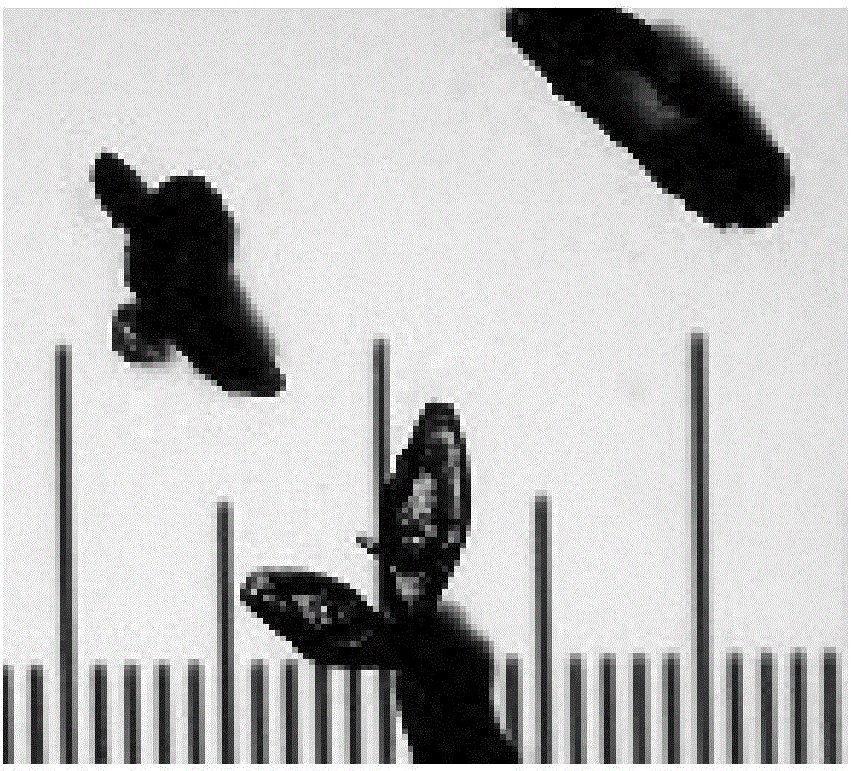

[0042] Filter, wash and dry ammonium metavanadate, the measured bulk density is 1.1g / cm 3 , using a microscope to observe the particle state, such as figure 2 .

[0043] Compared figure 1 and figure 2 , it can be seen that the crystal structure of ammonium metavanadate has changed from agglomerates of fine particles to single crystal particles.

Embodiment 2

[0045] Add 100g of ammonium metavanadate to 900ml of water, stir and add 1mol of potassium sulfate;

[0046] Raise the temperature to 85°C to dissolve ammonium metavanadate, remove insoluble matter by filtration, set the volume to 1000ml, V concentration is 1.28mol / L, potassium concentration is 2mol / L;

[0047] Add ammonia to adjust the pH to 9;

[0048] Keep the solution at 80°C, add 150g of ammonium sulfate, and stir to precipitate vanadium for 2 hours;

[0049] Cool down to room temperature and continue stirring for 1 h;

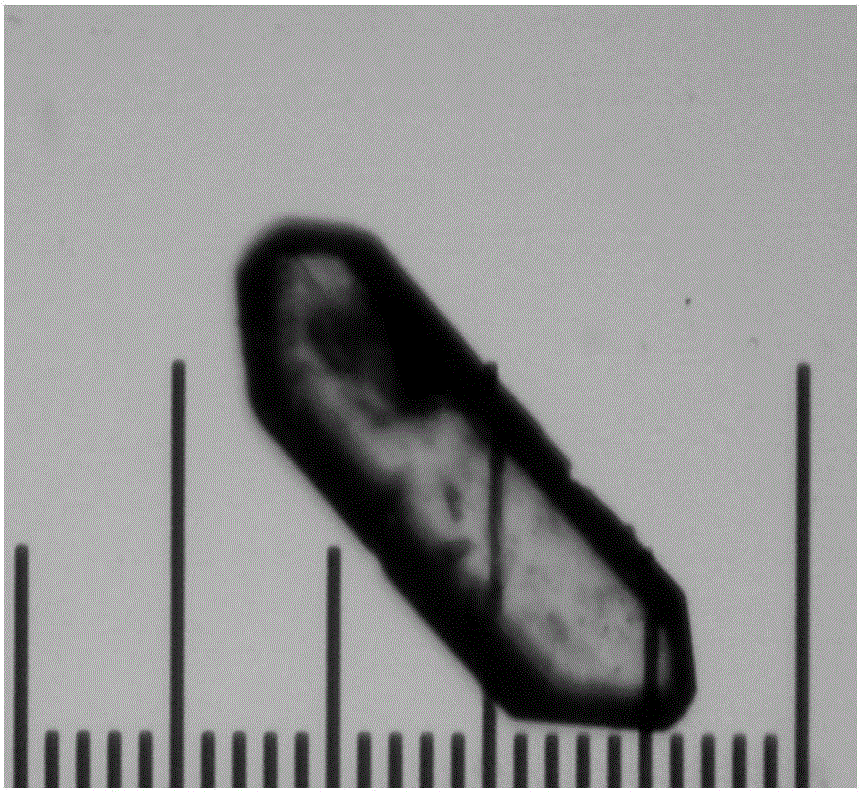

[0050] Filter, wash and dry ammonium metavanadate, the measured bulk density is 1.05g / cm 3

[0051] For micrographs of AMV see image 3 ,Compared figure 1 , figure 2 and image 3 It can be seen that the addition of additives can make ammonium metavanadate from polycrystalline polymerization into fine single crystals, adding additives and increasing the temperature of vanadium precipitation can obtain single crystals and large grains of ammonium me...

Embodiment 3

[0053] Use 1000ml of leaching solution after sodium roasting of vanadium-containing steel slag, containing 0.7mol / L NaVO 3 , containing sodium sulfate 2mol / l, the solution pH9.5.

[0054] Add 10g of magnesium sulfate and stir until completely dissolved;

[0055] The solution was heated to 90°C;

[0056] Add 130g of ammonium sulfate, stir and crystallize for 2h;

[0057] Cool down to room temperature and continue stirring for 1 h;

[0058] Filter, wash and dry ammonium metavanadate, the measured bulk density is 1.15g / cm3 。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com