A kind of welding tensioner processing method

A processing method and tensioner technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of shortened belt life, low production efficiency, and large number of rivets, reducing deformation resistance and low material utilization. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] A welding type tensioner processing technology, comprising the following steps:

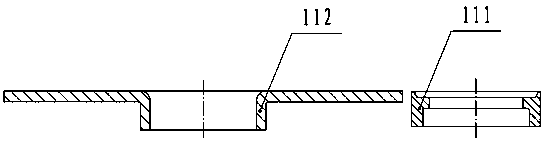

[0028] ①The two parts are formed separately: both are made of hot-rolled steel plates. The first part is to stretch the steel plate after blanking and punching to form a flange-shaped disc-shaped blank with a boss. Install the shaping mold on the hydraulic press. A blank is obtained after extrusion. The second part is to punch the disc-shaped steel plate after blanking and stretching to form a disc-shaped blank with grooves. Specifically, it includes stamping and preforming the center of the circular sheet steel plate, as shown in the attached figure 1 As shown, 112 is the second part of the blank with a boss, and the arc at the connection between the boss and the disc is as small as possible, and it is pre-processed for better material flow.

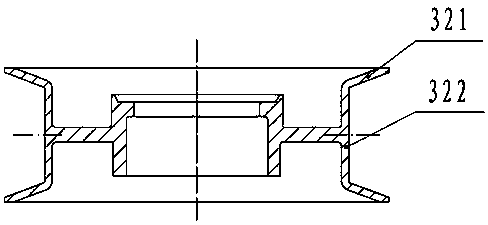

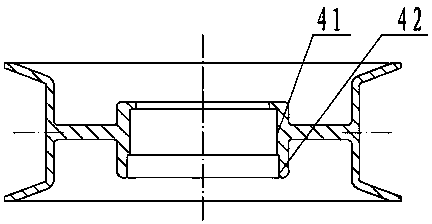

[0029] ②Friction welding: Instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com