Environment-friendly foaming liquid and preparation method thereof

An environmentally friendly and liquid technology, which is applied in the field of daily chemistry, can solve the problems of human skin irritation, poor stability of bubble liquid, and general bubble blowing effect, and achieve low raw material cost, simple production process, and large foaming quantity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

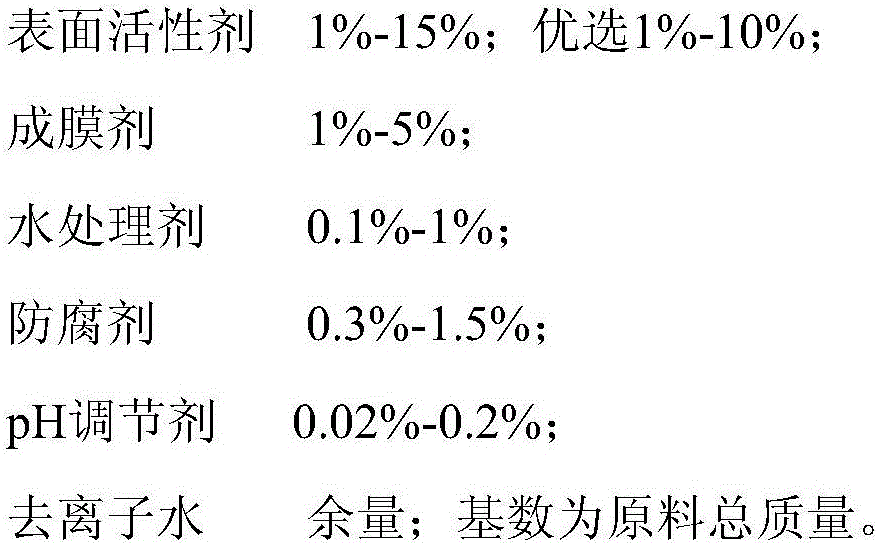

Method used

Image

Examples

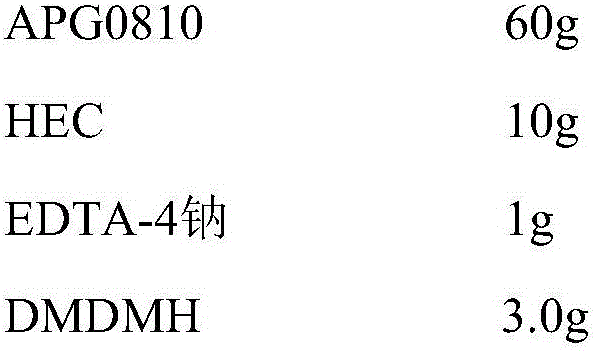

Embodiment 1

[0023] Recipe (total amount 1kg):

[0024]

[0025]

[0026] Production process: Add 925.8 grams of deionized water into a clean 1-ton reactor, start stirring, add 1 gram of EDTA-4 sodium, dissolve, add 10 grams of HEC and stir until dissolved, add 60 grams of APG0810, 3.0 grams of DMDMH, and stir until Dissolve evenly, and adjust the pH to 7-8 with citric acid.

[0027] With the above prepared liquid, at normal temperature, blow bubbles with a single-hole bubble blowing ring (2.5mm in diameter), up to 58 bubbles at a time, and the bubble breaking rate after blowing for 5 seconds is 5%.

Embodiment 2

[0029] Recipe (total amount 1kg):

[0030]

[0031] Production process: Add 932.8 grams of deionized water into a clean 1-ton reactor, start stirring, add 1 gram of EDTA-4 sodium, dissolve, add 8 grams of HEC and stir until dissolved, add 45 grams of APG0810, 10 grams of APG1214, 3.0 grams of DMDMH , stir until dissolved evenly, and adjust the pH to 7-8 with citric acid.

[0032] With the above prepared liquid, at normal temperature, blow bubbles with a single-hole bubble blowing ring (2.5 mm in diameter), up to 65 bubbles at a time, and the bubble breaking rate after blowing for 5 seconds is 4%.

Embodiment 3

[0034] Recipe (total amount 1kg):

[0035]

[0036] Production process: Add 923.8 grams of deionized water to a clean 1 ton reactor, start stirring, add 1 gram of EDTA-4 sodium, 15 grams of HEC to dissolve, add 5 grams of APG08105, 2 grams of essence, 3.0 grams of DMDMH, stir until it is evenly dissolved, Adjust the pH to 7-8 with citric acid.

[0037] With the above prepared liquid, at room temperature, blow bubbles with a single-hole bubble-blowing ring (2.5mm in diameter), up to 56 bubbles at a time, and the bubble-breaking rate after blowing for 5 seconds is 6%; Ring (diameter 19.5mm) to blow bubbles, up to 7 at a time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com