Method for preparing waterproof material by modifying surfaces of sisal fibers with water-based organosilicone

A technology of sisal fiber and waterproof material, which is applied in the direction of liquid repellent fiber, fiber treatment, plant fiber, etc., can solve the problems of complicated technical process and high cost, and achieve the effect of broadening research and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

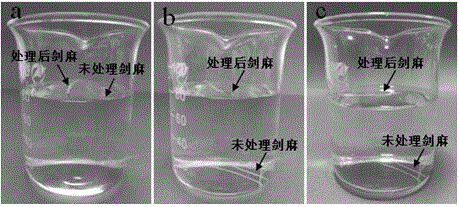

Image

Examples

Embodiment 1

[0015] 200 μL of silane coupling agent methyltrimethoxysilane was added dropwise to 105 g of PDMS emulsion (10% solid content), stirred and mixed evenly to obtain silicone emulsion immersion solution; sisal fibers were soaked in water after washing and drying In the immersion solution, ultrasonically disperse for 5 minutes, after soaking evenly, take out the sisal fiber and remove the excess immersion solution, and then place it at room temperature for curing to obtain the modified sisal fiber.

Embodiment 2

[0017] Add 500 μL of silane coupling agent methyltrimethoxysilane dropwise to 200 g of PDMS emulsion (solid content 10%), stir and mix evenly to obtain silicone emulsion immersion solution; wash and dry sisal fiber soaked in In the immersion solution, ultrasonically disperse for 5 minutes, after soaking evenly, take out the sisal fiber and remove the excess immersion solution, and then place it at room temperature for curing to obtain the modified sisal fiber.

Embodiment 3

[0019] Add 200 μL of silane coupling agent KH-550 dropwise to 105 g of PDMS emulsion (solid content 10%), stir and mix evenly to obtain a silicone emulsion immersion solution; soak the sisal fiber after washing and drying in the immersion solution , ultrasonically dispersed for 5 min, soaked evenly, took out the sisal fiber and removed the excess immersion liquid, and then placed it at room temperature to solidify, that is, the modified sisal fiber was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com