Preparation method for whisker carbon nanotube-reinforced aluminum matrix composite coated with aluminum oxide

A technology of coating alumina and carbon nanotubes, which is applied in the field of material preparation and forming, can solve the problems of unfavorable performance improvement of composite materials, lack of preparation and forming technology of carbon nanotube-reinforced aluminum-based composite materials, and easy agglomeration of CNTs, etc., to achieve simple and effective Difficulty of operation, reducing the chance of reunion, avoiding the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

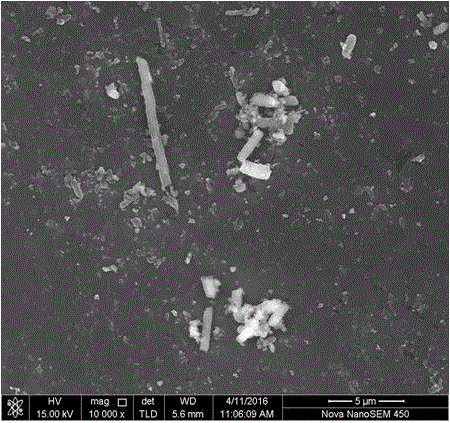

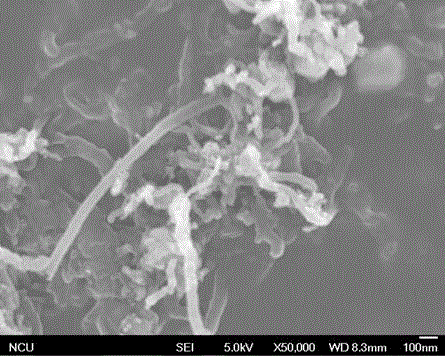

[0034] Whiskered carbon nanotubes were ultrasonically pre-dispersed in pure nitric acid solution for 8 hours at 60°C. After cooling to room temperature, they were washed with deionized water, centrifuged until neutral, and dried in a vacuum oven for later use. Using aluminum nitrate and the above-mentioned dried whisker carbon nanotubes as raw materials, add them into a methanol solution and sonicate for 40 minutes; wherein the molar ratio of whisker carbon nanotubes, aluminum nitrate and methanol is 1:0.4:182, and the suspension of whisker carbon nanotubes is obtained. Turbid liquid; import the suspension into the hydrothermal reaction kettle, wherein the volume of the suspension accounts for 25% of the volume of the reaction kettle. Then put it into the reaction furnace to heat, raise the temperature to 100°C at 5°C / min, keep it for 1h, then raise the temperature to 150°C at 3°C / min, keep it for 8h; cool it to room temperature at 5°C / min, filter and dry at low temperature Pu...

Embodiment 2

[0037] Whiskered carbon nanotubes were ultrasonically pre-dispersed in pure nitric acid solution for 8 hours at 60°C. After cooling to room temperature, they were washed with deionized water, centrifuged until neutral, and dried in a vacuum oven for later use. Using aluminum nitrate and the above-mentioned dried whisker carbon nanotubes as raw materials, add methanol solution to ultrasonic for 40 minutes; wherein the molar ratio of carbon nanotubes, aluminum nitrate and methanol is 1:0.7:182, to obtain whisker carbon nanotube suspension ; This suspension is imported in the hydrothermal reactor, wherein the volume of the suspension accounts for 30% of the volume of the reactor. Then put it into the reaction furnace to heat, raise the temperature to 120°C at 3°C / min, keep it for 1h, then raise the temperature to 150°C at 1°C / min, keep it for 10h; cool it to room temperature at 7°C / min, filter and dry at low temperature Put it into a corundum crucible and bake at a high temperatu...

Embodiment 3

[0040] Whiskered carbon nanotubes were ultrasonically pre-dispersed in pure nitric acid solution for 8 hours at 60°C. After cooling to room temperature, they were washed with deionized water, centrifuged until neutral, and dried in a vacuum oven for later use. Using aluminum nitrate and the above-mentioned dried whisker carbon nanotubes as raw materials, add them into a methanol solution and sonicate for 60 minutes; wherein the molar ratio of whisker carbon nanotubes, aluminum nitrate and methanol is 1:1:182, and the suspension of whisker carbon nanotubes is obtained. Turbid liquid; import the suspension into the hydrothermal reaction kettle, wherein the volume of the suspension accounts for 40% of the volume of the reaction kettle. Then put it into the reaction furnace to heat, raise the temperature to 120°C at 3°C / min, keep it for 1h, then raise the temperature to 150°C at 1°C / min, keep it for 12h; cool it to room temperature at 10°C / min, filter and dry at low temperature Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com