Preparation method of titanium dioxide/copper oxide composited oxide nanometer material

A composite oxide and titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, metal/metal oxide/metal hydroxide catalysts, etc. Low activity and other problems, to achieve the effect of easy operation and control, low preparation cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

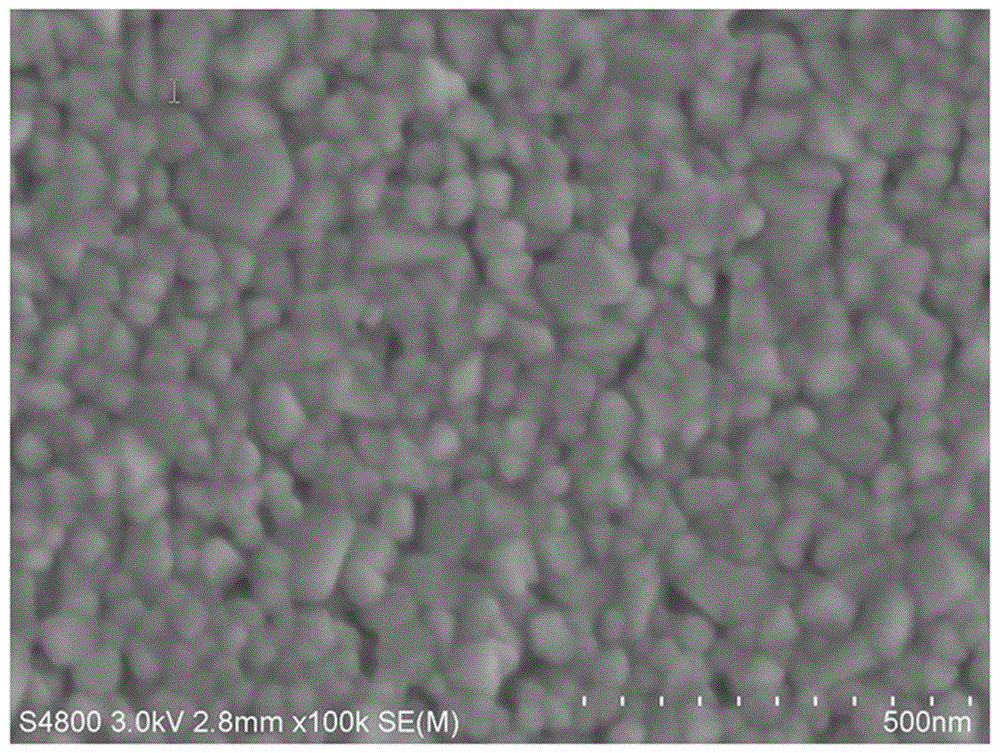

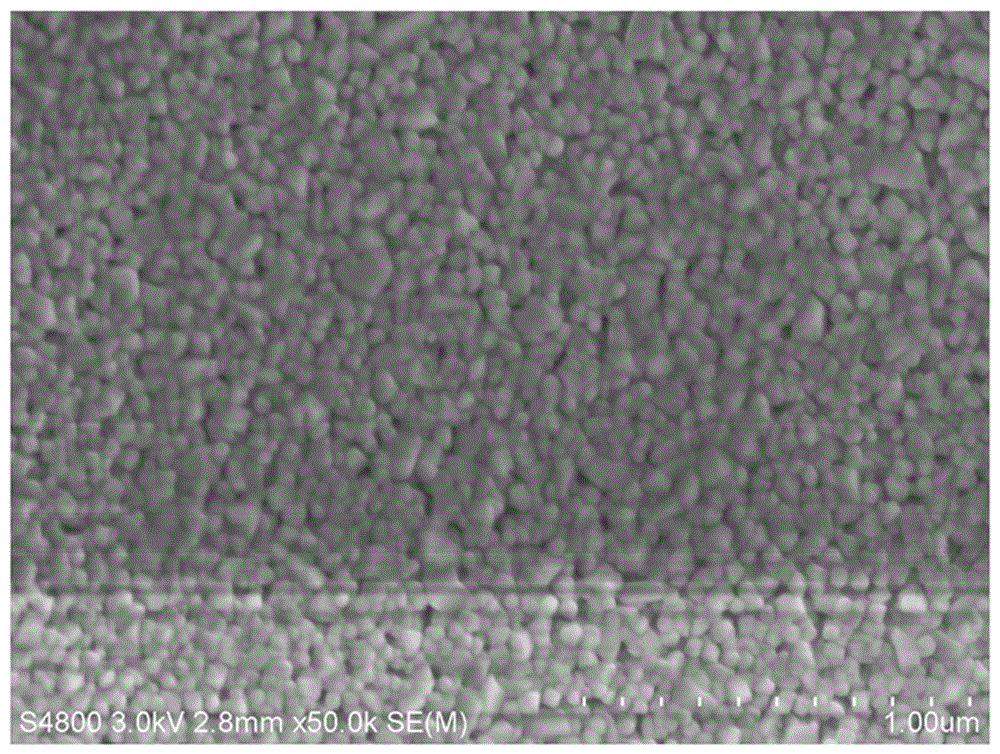

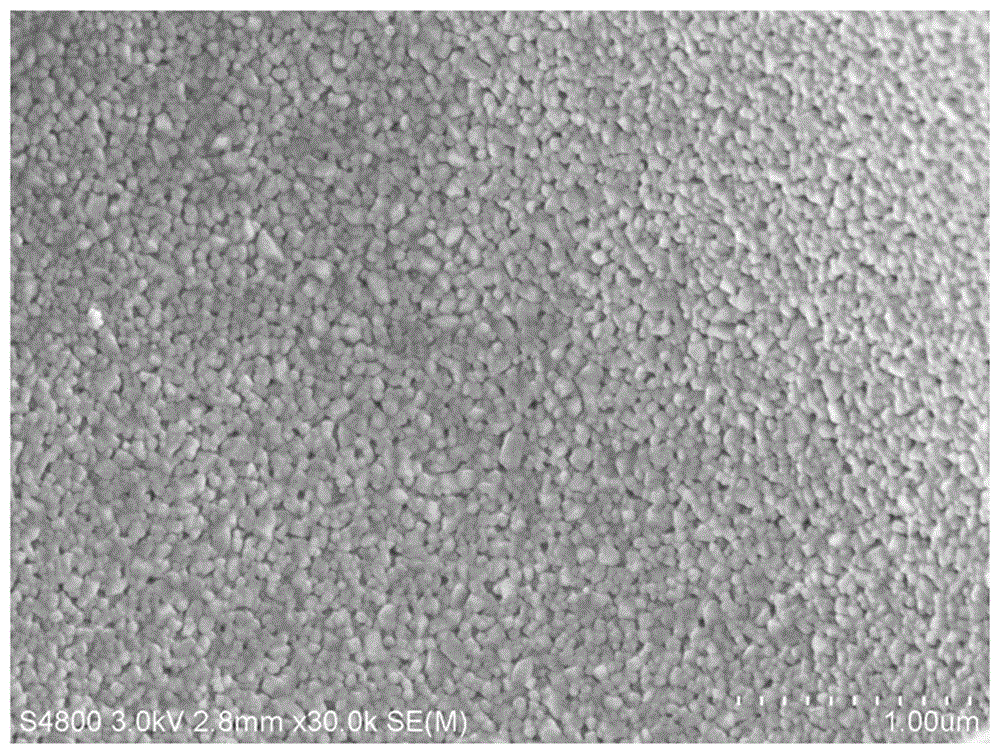

Image

Examples

Embodiment 1

[0032] (1) Dissolve copper acetylacetonate in DMF solution, solvothermal reaction, and obtain a DMF solution of nano-cuprous oxide after cooling, wherein the molar concentration of copper acetylacetonate in DMF solution is 0.1 mol / L, and the solvothermal reaction temperature is 200°C, the reaction time is 12 hours. (2) Dissolve tetrabutyl titanate in oxalic acid aqueous solution, then add the above-mentioned DMF solution of nano-cuprous oxide, evaporate the solvent under the condition of heating and stirring, and carry out cross-linking reaction, wherein the molar concentration of oxalic acid is 0.5 mol / L, the molar ratio of tetrabutyl titanate to oxalic acid is 1:5, the molar ratio of tetrabutyl titanate to nano-cuprous oxide is 1:0.05, the heating temperature is 100 °C, and the stirring speed is 60 rpm . After evaporating to dryness, carry out the cross-linking reaction, the reaction temperature is 200 °C, and the reaction time is 2 hours. After the cross-linking reaction i...

Embodiment 2

[0035](1) Dissolve copper acetylacetonate in DMF solution, solvothermal reaction, and obtain a DMF solution of nano-cuprous oxide after cooling, wherein the molar concentration of copper acetylacetonate in DMF solution is 0.05 mol / L, and the solvothermal reaction temperature is 180°C, the reaction time is 24 hours. (2) Dissolve tetrabutyl titanate in oxalic acid aqueous solution, then add the above-mentioned DMF solution of nano-cuprous oxide, evaporate the solvent under the condition of heating and stirring, and carry out cross-linking reaction, wherein the molar concentration of oxalic acid is 0.5 mol / L, the molar ratio of tetrabutyl titanate to oxalic acid is 1:5, the molar ratio of tetrabutyl titanate to nano-cuprous oxide is 1:0.5, the heating temperature is 120 °C, and the stirring speed is 60 rpm . After evaporating to dryness, carry out the cross-linking reaction, the reaction temperature is 200 °C, and the reaction time is 2 hours. After the cross-linking reaction is...

Embodiment 3

[0038] (1) Dissolve copper acetylacetonate in DMF solution, solvothermal reaction, and obtain a DMF solution of nano-cuprous oxide after cooling, wherein the molar concentration of copper acetylacetonate in DMF solution is 0.05 mol / L, and the solvothermal reaction temperature is 180°C, the reaction time is 24 hours. (2) Dissolve tetrabutyl titanate in oxalic acid aqueous solution, then add the above-mentioned DMF solution of nano-cuprous oxide, evaporate the solvent under the condition of heating and stirring, and carry out cross-linking reaction, wherein the molar concentration of oxalic acid is 0.5 mol / L, the molar ratio of tetrabutyl titanate to oxalic acid is 1:5, the molar ratio of tetrabutyl titanate to nano-cuprous oxide is 1:0.2, the heating temperature is 120 °C, and the stirring speed is 60 rpm . After evaporating to dryness, carry out the cross-linking reaction, the reaction temperature is 200 °C, and the reaction time is 2 hours. After the cross-linking reaction i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com