Preparation method and application of spherical carbon electrode material

A technology of electrode material and spherical carbon, which is applied in the preparation/purification of carbon, nanotechnology for materials and surface science, battery electrodes, etc., which can solve the problems of unfavorable large-scale production, harsh preparation conditions, and poor cycle performance , to achieve the effect of small particle size, low cost and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add distilled water into the reaction kettle at room temperature, add ammonia water to the distilled water and stir evenly, then add formaldehyde solution (37% by mass), and add resorcinol solid particles under stirring; wherein, the amount of ammonia water added is 0.004g / mL, the amount of formaldehyde solution added is 0.02g / mL, and the amount of resorcinol solid particles added is 0.005g / mL;

[0033] (2) The mixed solution obtained in step (1) is subjected to ultrasonic dispersion treatment under magnetic stirring (time is 30min, ultrasonic power is 60W, and ultrasonic treatment is performed for 5s at intervals of 5s during the treatment process). After the ultrasonic dispersion treatment is completed, the solution is stirred at room temperature Reaction completely obtains phenolic resin microsphere;

[0034] (3) Dry the phenolic resin microspheres obtained in step (2) and then carbonize them in an inert gas to obtain spherical carbon electrode materials. Incuba...

Embodiment 2

[0040] (1) Add distilled water into the reaction kettle at room temperature, add ammonia water to the distilled water and stir evenly, then add formaldehyde solution (38% by mass), and add resorcinol solid particles under stirring; wherein, the amount of ammonia water added is 0.001g / mL, the amount of formaldehyde solution added is 0.04g / mL, and the amount of resorcinol solid particles added is 0.003g / mL;

[0041] (2) The mixed solution obtained in step (1) was subjected to ultrasonic dispersion treatment under magnetic stirring (the time is 50min, the ultrasonic power is 80W, and the ultrasonic treatment is performed for 6s at intervals of 3s during the treatment process). After the ultrasonic dispersion treatment, the solution was stirred at room temperature Reaction completely obtains phenolic resin microsphere;

[0042] (3) Dry the phenolic resin microspheres obtained in step (2) and then carbonize them in an inert gas to obtain spherical carbon electrode materials. Incub...

example 2

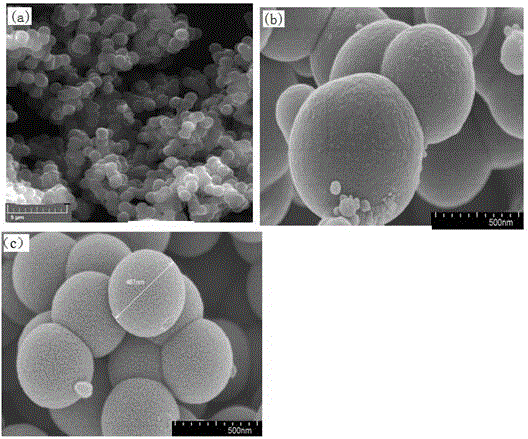

[0044] The spherical phenolic resin carbon microspheres prepared by example 2 are as figure 1 As shown in (b), the spherical carbon material is obtained by carbonizing the phenolic resin under a high-temperature inert atmosphere, and the material retains the standard spherical structure of the precursor. The carbon electrode material prepared in this embodiment is at 90 mA g -1 Under the current density, the charge and discharge performance under the voltage of 0.05-3V is as follows: Figure 7 As shown, the first discharge specific capacity at this current density is 482.44 mA h g -1 , with a capacity retention of 440 mA h g after 10 cycles -1 , after 50 cycles the discharge specific capacity still maintains 416 mA h g -1 . It shows that the material has very good charge and discharge performance as the negative electrode material of lithium ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com