Graphene/copper nano wire composite film and preparation method thereof

A technology of copper nanowires and composite films, applied in metal/alloy conductors, cable/conductor manufacturing, carbon-silicon compound conductors, etc., can solve the problems of instable graphene performance, difficult transfer process, lack of simple operation, etc. Thermal and electrical conductivity, good controllability, and the effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

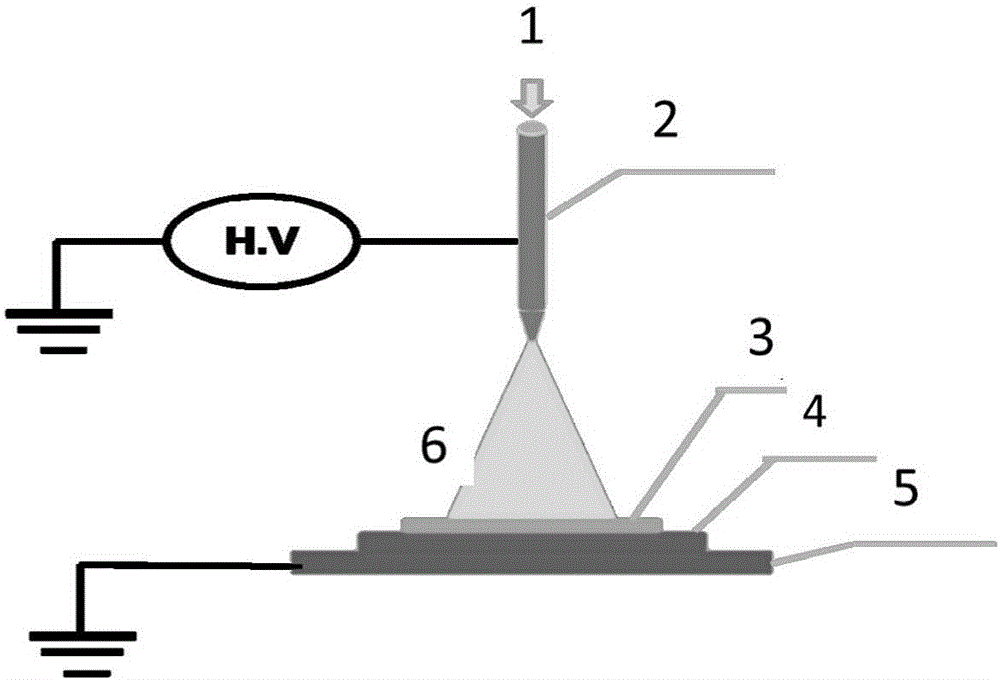

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of a kind of graphene / copper nanowire composite film described in the present embodiment is specifically carried out according to the following steps:

[0036] 1) Preparation of copper nanowire dispersion: 384g NaOH was dissolved in 640mL deionized water; 0.387g Cu(NO3) 2 Dissolve 3H2O in 32mL deionized water, stir magnetically for 10min; mix Cu(NO3) 2 The solution was slowly added to the NaOH solution; 165 μL of hydrazine hydrate and 2.4 ml of ethylenediamine were added to the above solution, and magnetically stirred for 5 minutes; heated in a water bath at 60°C for 4 hours; washed with deionized water by centrifugation, and the process was repeated 4 times; frozen After drying, disperse in aqueous solution to obtain copper nanowires;

[0037] Disperse copper nanowires in N-methylpyrrolidone: disperse the prepared copper nanowires in N-methylpyrrolidone, and perform ultrasonic treatment for 30 minutes at a frequency of 100KHz to obtain a copper ...

Embodiment 2

[0053] The preparation method of a kind of graphene / copper nanowire composite film described in the present embodiment is specifically carried out according to the following steps:

[0054] 1) Preparation of copper nanowire dispersion: 384g NaOH was dissolved in 640mL deionized water; 0.387g Cu(NO3) 2 Dissolve 3H2O in 32mL deionized water, stir magnetically for 5min; mix Cu(NO3) 2 The solution was slowly added to the NaOH solution; 165 μL of hydrazine hydrate and 2.4 ml of ethylenediamine were added to the above solution, and magnetically stirred for 5 minutes; heated in a water bath at 60°C for 4 hours; washed by centrifugation with deionized water, and the process was repeated 6 times; frozen After being dried, it is dispersed in an aqueous solution to obtain a copper nanowire solution;

[0055] Disperse copper nanowires in N-methylpyrrolidone: disperse the prepared copper nanowires in N-methylpyrrolidone, and perform ultrasonic treatment for 60 minutes at a frequency of 10...

Embodiment 3

[0068] The preparation method of a kind of graphene / copper nanowire composite film described in the present embodiment is specifically carried out according to the following steps:

[0069] 1) Preparation of copper nanowire dispersion: 384g NaOH was dissolved in 640mL deionized water; 0.387g Cu(NO3) 2 Dissolve 3H2O in 32mL deionized water, stir magnetically for 10min; mix Cu(NO3) 2 The solution was slowly added to the NaOH solution; 165 μL of hydrazine hydrate and 2.4 ml of ethylenediamine were added to the above solution, and magnetically stirred for 5 minutes; heated in a water bath at 60°C for 4 hours; washed with ethanol by centrifugation, and the process was repeated 5 times; after freeze-drying Disperse in an aqueous solution to obtain copper nanowires;

[0070] Disperse copper nanowires in N-methylpyrrolidone: disperse the prepared copper nanowires in N-methylpyrrolidone, and perform ultrasonic treatment at a frequency of 50KHz for 45min to obtain a copper nanowire dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com