Alkaline three-in-one aluminum pretreatment with pot liquid and aluminum hydroxide online recovery system

A technology of aluminum hydroxide and recovery system, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, aluminum compounds, inorganic chemistry, etc., which can solve complex processes, pay environmental protection costs, and increase waste water containing fluorine and ammonia nitrogen Pressure and other problems, to achieve the effect of increasing the concentration of free alkali, reducing the cost of treatment, and fully recovering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] Embodiment 1 (sand surface material)

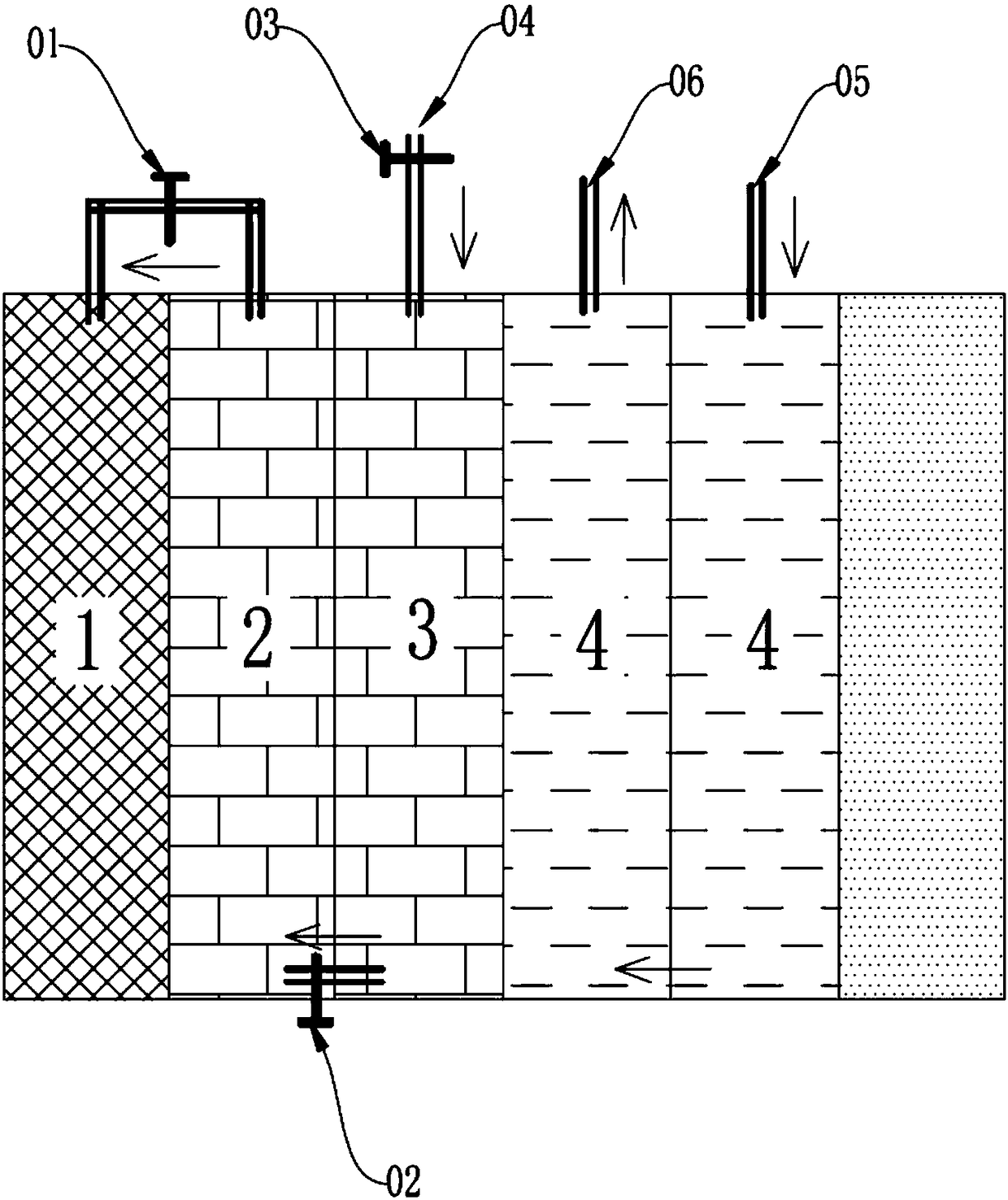

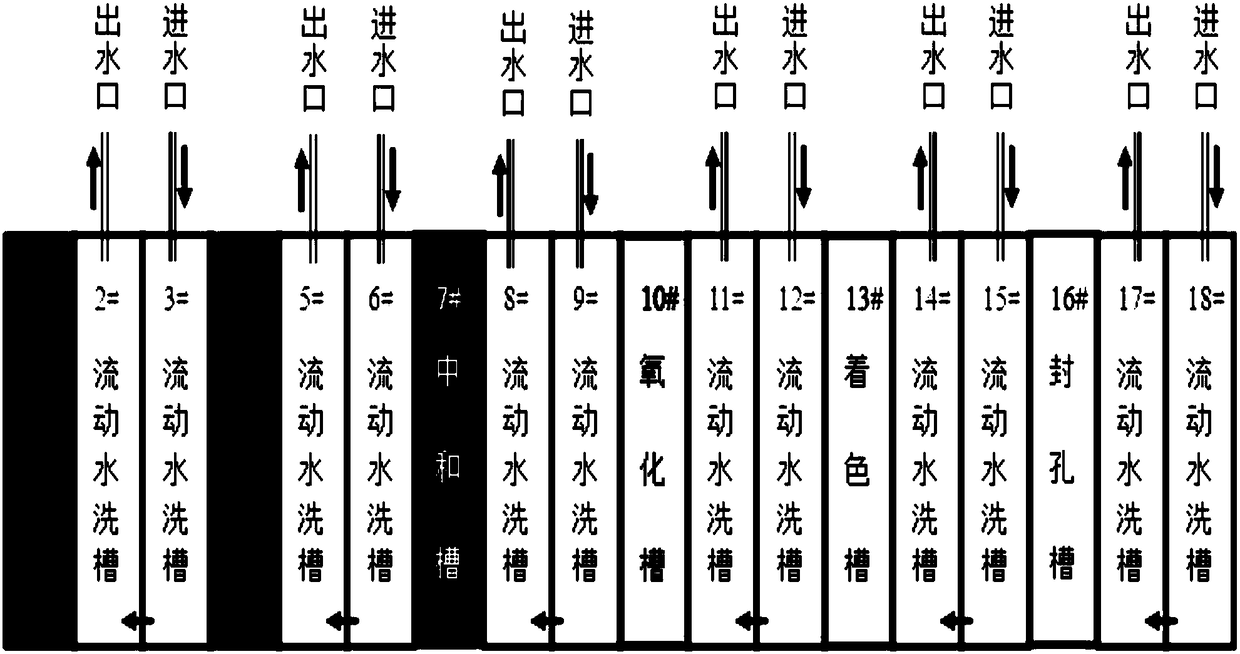

[0130] Aluminum directly enters the alkaline three-in-one grinding tank 1, R(NaOH / Al 3+ )3.75, NaCl30g / L, react for 10-15 minutes, 50-60°C, trickle for 1 minute; wash in the first non-flowing water washing tank 2 for 1.5 minutes, trickle for 1 minute, and wash in the second non-flowing water washing tank 3 for 1 minute , trickle for 1 minute; enter two flowing water washing tanks, wash for 1 minute and 1 trickle for 1 minute, and complete the pre-oxidation treatment.

Embodiment 2

[0131] Embodiment 2 (sand blasting material)

[0132] Aluminum directly enters the alkaline three-in-one grinding tank 1, R(NaOH / Al 3+ )3.75, NaCl30g / L, react for 5-10 minutes, 50-60°C, trickle for 1 minute; wash in the first non-flowing water washing tank 2 for 1.5 minutes, trickle for 1 minute, and wash in the second non-flowing water washing tank 3 for 1 minute , trickle for 1 minute; enter two flowing water washing tanks, wash for 1 minute and 1 trickle for 1 minute, and complete the pre-oxidation treatment.

[0133] Shown by embodiment 1-2, alkaline etching solution of the present invention can produce chemical frosting material and mechanical sandblasting material.

Embodiment 3

[0134] Embodiment 3 (sanding ability of NaCl)

[0135] According to Table 1, the aluminum material directly enters the alkaline three-in-one grinding tank 1, R(NaOH / Al 3+ )3.75, NaCl 0g / L, react for 5-10 minutes, 50-60°C, trickle for 1 minute; wash in the first non-flowing water washing tank 2 for 1.5 minutes, trickle for 1 minute, and wash in the second non-flowing water washing tank 3 for 1 minutes, trickle for 1 minute; enter two flowing water washing tanks, wash for 1 minute and trickle for 1 minute respectively, and complete the pre-oxidation treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com