High-stretching-ratio-resisting adhesive for cable shielding film

A cable shielding and elongation technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., to achieve the effect of no cracks, increased adhesion, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

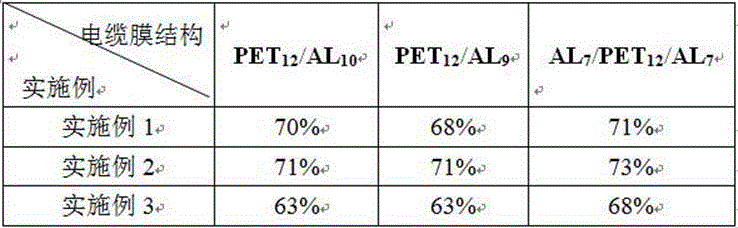

Examples

Embodiment 1

[0030] The high-stretch-resistant adhesive for cable shielding film provided in this example includes a main agent and a curing agent, and the mass ratio of the main agent and curing agent is 100:3, wherein the main agent is a polyurethane macromolecule The molecular weight is 19600, the hydroxyl value is 5.9mgKOH / g, the solid content is 50%, and the rotational viscosity at 25°C is 1200mPa.s.

[0031] The polyurethane macromolecule is mainly synthesized by using polyester polyol, isocyanate, ethyl acetate, catalyst a and defoamer as raw materials.

[0032] (1) Synthesize polyester polyol first

[0033] Polyester polyols are mainly synthesized from neopentyl glycol, diethylene glycol, 1,2-propylene glycol, small molecule polyols, terephthalic acid, isophthalic acid, sebacic acid and catalyst b, and the hydroxyl groups of polyester polyols The value is 40~50mgKOH / g, acid value<2mgKOH / g, glass transition temperature≤-15℃.

[0034] Wherein the mass parts of neopentyl glycol, die...

Embodiment 2

[0050] The high-stretch-resistant adhesive for cable shielding film provided in this example includes a main agent and a curing agent, and the mass ratio of the main agent and curing agent is 100:3, wherein the main agent is a polyurethane macromolecule The molecular weight is 22170, the hydroxyl value is 5.6mgKOH / g, the solid content is 50%, and the rotational viscosity at 25°C is 1300mPa.s.

[0051] The polyurethane macromolecule is mainly synthesized by using polyester polyol, isocyanate, ethyl acetate, catalyst a and defoamer as raw materials.

[0052] (1) Synthesize polyester polyol first

[0053] Polyester polyols are mainly synthesized from neopentyl glycol, diethylene glycol, 1,2-propylene glycol, small molecule polyols, terephthalic acid, isophthalic acid, sebacic acid and catalyst b, and the hydroxyl groups of polyester polyols The value is 40~50mgKOH / g, acid value<2mgKOH / g, glass transition temperature≤-15℃.

[0054] Wherein the mass parts of neopentyl glycol, die...

Embodiment 3

[0071] The high-stretch-resistant adhesive for cable shielding film provided in this example includes a main agent and a curing agent, and the mass ratio of the main agent and curing agent is 100:3, wherein the main agent is a polyurethane macromolecule The molecular weight is 24380, the hydroxyl value is 4.8mgKOH / g, the solid content is 50%, and the rotational viscosity at 25°C is 1300mPa.s.

[0072] The polyurethane macromolecule is mainly synthesized by using polyester polyol, isocyanate, ethyl acetate, catalyst a and defoamer as raw materials.

[0073] (1) Synthesize polyester polyol first

[0074] Polyester polyols are mainly synthesized from neopentyl glycol, diethylene glycol, 1,2-propanediol, small molecule polyols, terephthalic acid, isophthalic acid, adipic acid and catalyst b, and the hydroxyl groups of polyester polyols The value is 40~50mgKOH / g, acid value<2mgKOH / g, glass transition temperature≤-15℃.

[0075] Wherein the mass parts of neopentyl glycol, diethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com