Low-density carbon/carbon heat preservation material oxidation-resistant coating and preparation process thereof

An anti-oxidation coating and thermal insulation material technology, which is applied in the field of thermal insulation and thermal field material accessories, can solve problems such as poor affinity of coating agents, cracks between layers, and coating failure, so as to prevent matrix damage and stress concentration. Effects of enhancing adhesion and improving affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

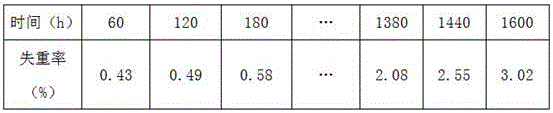

Embodiment 1

[0034] The anti-oxidation coating of the low-density carbon / carbon thermal insulation material of this embodiment is composed of two parts, an inner primer coating and an outer coating;

[0035] The inner primer coating is made of the following raw materials in parts by weight: 60 parts of graphite milk, 40 parts of resin and curing agent;

[0036] The outer coating is made of the following raw materials in parts by weight: 60 parts of graphite milk, 60 parts of resin and curing agent, 15 parts of sintering aid, and 15 parts of binder.

[0037] The fixed carbon content of described graphite milk is 99%, and metal element impurity content is lower than 200ppm; Described resin and curing agent are water-based two-component epoxy resin and epoxy resin curing agent, and epoxy resin: curing agent=2 : 1; the sintering aid is silicon powder, the purity is 95%, and its particle size is 100 mesh; the binder is methyl silane.

[0038] The preparation process of the anti-oxidation coati...

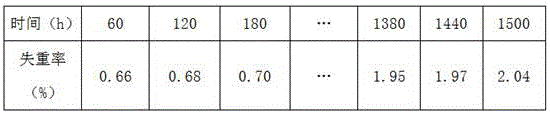

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is only:

[0050] The inner primer coating is made of the following raw materials in parts by weight: 100 parts of graphite milk;

[0051] The outer coating is made of the following raw materials in parts by weight: 30 parts of graphite milk, 100 parts of resin and curing agent, 10 parts of sintering aid, and 10 parts of binder.

[0052] The fixed carbon content of the graphite milk is 99.5%, and the impurity content of metal elements is lower than 100ppm; the sintering aid is graphite powder, the purity is 98.5%, and its particle size is 100 mesh; the binder is methyl silicon resin.

[0053] The preparation process of the anti-oxidation coating of the low-density carbon / carbon thermal insulation material of the present embodiment comprises the following steps:

[0054] (1) Surface treatment: the density to be coated is 0.18g / cm 3 , with an outer diameter of 1015mm and a thickness of 60mm, the dust and burrs on ...

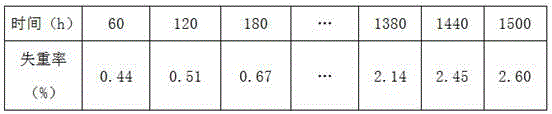

Embodiment 3

[0064] The difference between this embodiment and embodiment 1 is only:

[0065] The inner primer coating is made of the following raw materials in parts by weight: 40 parts of graphite milk, 60 parts of resin and curing agent;

[0066] The outer coating is made of the following raw materials in parts by weight: 45 parts of graphite milk, 80 parts of resin and curing agent, 2 parts of sintering aid, and 2 parts of binder.

[0067] The fixed carbon content of the graphite milk is 99.8%, and the impurity content of metal elements is lower than 80ppm; the sintering aid is pitch powder, the purity is 99.0%, and its particle size is 120 mesh; the binder is methyl fiber white.

[0068] The preparation process of the anti-oxidation coating of the low-density carbon / carbon thermal insulation material of the present embodiment comprises the following steps:

[0069] (1) Surface treatment: the density of the coating to be 0.15g / cm 3 , with an outer diameter of 1015mm, an inner diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com