Cutting-resistant ultra high molecular weight polyethylene fiber, preparation method and application thereof

A polyethylene fiber, ultra-high molecular weight technology, applied in the field of fiber materials, can solve the problems of increased product cost, uncomfortable wearing, difficult post-processing, etc., and achieves the effect of reducing post-processing performance and wearing performance, and improving cutting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0025] Embodiments 1-12 provide a kind of cutting-resistant ultra-high molecular weight polyethylene fiber respectively, and its preparation process refers to the parameters in Comparative Example 1, and the difference is that rod-shaped particles are also added during swelling, so that each rod-shaped particle accounts for the proportion of rod-shaped particles and powdery particles. The percentages of the total mass of UHMWPE are respectively: magnesium borate whiskers (the Mohs hardness is 6, the aspect ratio is about 10, and the diameter is about 10 microns) 3wt% (embodiment 1), magnesium borate whiskers (the Mohs hardness is 6 , aspect ratio is about 10, diameter is about 10 microns) 6wt% (embodiment 2), magnesium borate whisker (Mohs hardness is 6, aspect ratio is about 10, diameter is about 10 microns) 7wt% (implementation Example 3), magnesium borate whisker (Mohs hardness is 6, aspect ratio is about 2, diameter is about 10 microns) 7wt% (embodiment 4), magnesium borate...

Embodiment 13

[0027] The present embodiment provides a cut-resistant ultra-high molecular weight polyethylene fiber, and its preparation process refers to the parameters in Comparative Example 1. The ratio is about 20, the diameter is about 10 microns) and the total mass concentration of powdered UHMWPE is 8.3%, and the weight ratio of silicon dioxide and UHMWPE is 11:99.

Embodiment 14

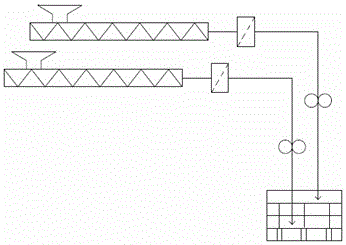

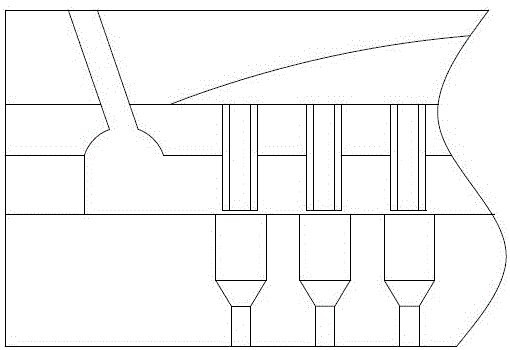

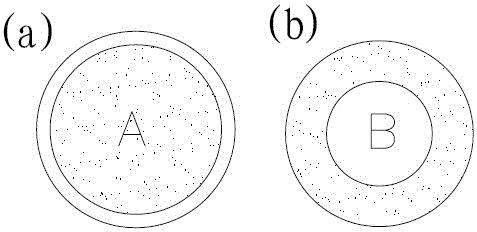

[0029] This embodiment provides a cut-resistant ultra-high molecular weight polyethylene fiber, the process parameters of the preparation are basically the same as those in Example 8, the difference is that it adopts figure 1 The process flow shown and adopt as figure 2 The existing sheath-core type spinning group shown, obtains as image 3 The ultra-high molecular weight polyethylene fiber containing silica in the core layer shown in (a) (the total addition of silica in the skin layer and the core layer is about 11 wt%). The finished filaments prepared in this way can avoid white powder and equipment wear during post-processing. It is found that the finished filaments in the relaxed state sometimes have self-crimping and fluffy that can be observed, which may be due to the difference between the center of the core layer nozzle and the center of the cortex nozzle hole. Minor positional deviation, or due to the slight viscosity difference between the core spinning solution an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com