Silicon carbide particle shaping device

A silicon carbide particle and shaping device technology, applied in grain processing and other directions, can solve the problems of difficulty in meeting customer specific gravity requirements, reducing the output of silicon carbide micropowder, and large investment in jet mills, achieving reasonable design, reducing sharpness, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

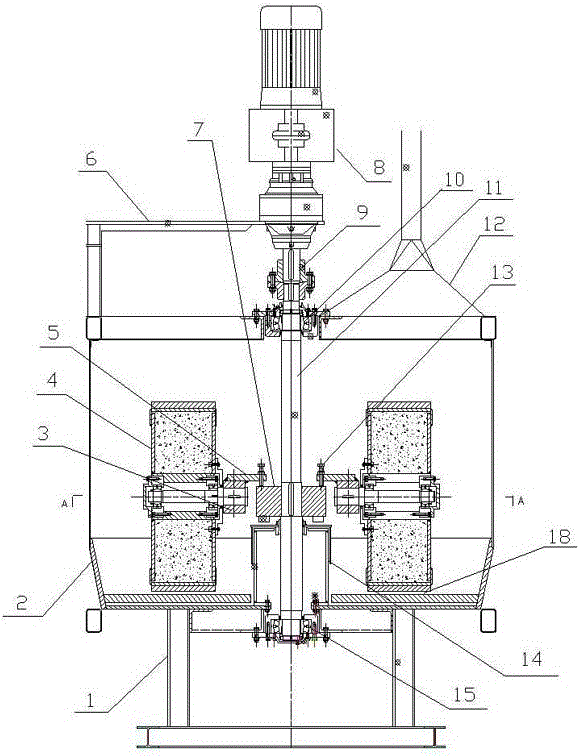

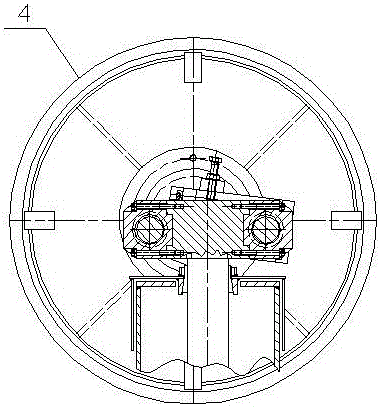

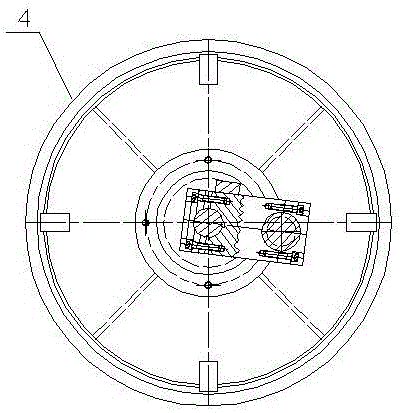

[0023] Embodiment 1, with reference to Figure 1-4 , a shaping device for silicon carbide granules, is provided with a shaping frame 1, and a grinding plate 2 is mounted on the shaping frame 1, and the bottom of the grinding plate 2 is provided with a discharge port, and the discharge port is provided with a gate valve, and the grinding plate 1 is provided with a vertical To the main shaft 11 that is arranged, the upper end of the main shaft 11 joins with the shaping frame 1 through the main bearing 10, the lower end of the main shaft 11 passes through the grinding plate 2 and connects with the lower bearing 15 arranged on the shaping frame 1, and the grinding plate 2 along the circumference of the main shaft 11 A plurality of grinding wheels 4 matched with the bottom of the grinding disc 2 are evenly arranged, and a shaping gap 18 of silicon carbide is provided between the bottom of the grinding wheel 4 and the bottom of the grinding disc 2, and the bottom of the main shaft 11...

Embodiment 2

[0026] Embodiment 2, the shaping device of silicon carbide particles described in embodiment 1, the described axle support mechanism includes a connecting body 3 and a support frame 7 installed at the inner end of the wheel shaft of the roller 4, and the support frame 7 is provided with the main shaft 11. Cooperating bushing, connecting body 3 is mounted on the support frame 7 through the connecting arm 5, and the buffer mechanism of the roller 4 is arranged between the connecting arm 5 and the supporting frame 7, and the connecting arm 5 is protected by the buffer mechanism to prevent deformation and extend service life.

Embodiment 3

[0027] Embodiment 3, the shaping device for silicon carbide particles described in Embodiment 2, the buffer mechanism is provided with a vertical bolt 13 that passes through the connecting arm 5 and is mounted on the support frame 7, and the bottom of the connecting arm 5 and the support frame 7 The vertical bolts 13 in between are provided with supporting springs, and the vertical bolts 13 above the connecting arm 5 are provided with adjusting nuts, which can adjust the extrusion force of silicon carbide, shorten the shaping time, and improve the shaping speed and efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com