A kind of manufacturing method of superconducting magnet for high temperature superconducting maglev train

A technology for maglev trains and superconducting magnets, applied in superconducting magnets/coils, magnetic core manufacturing, magnetic objects, etc., can solve the problems of levitation force and guiding force to be improved, low critical current density, etc., and achieve high critical current density , the critical current density increase, the levitation force and the effect of guiding force increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

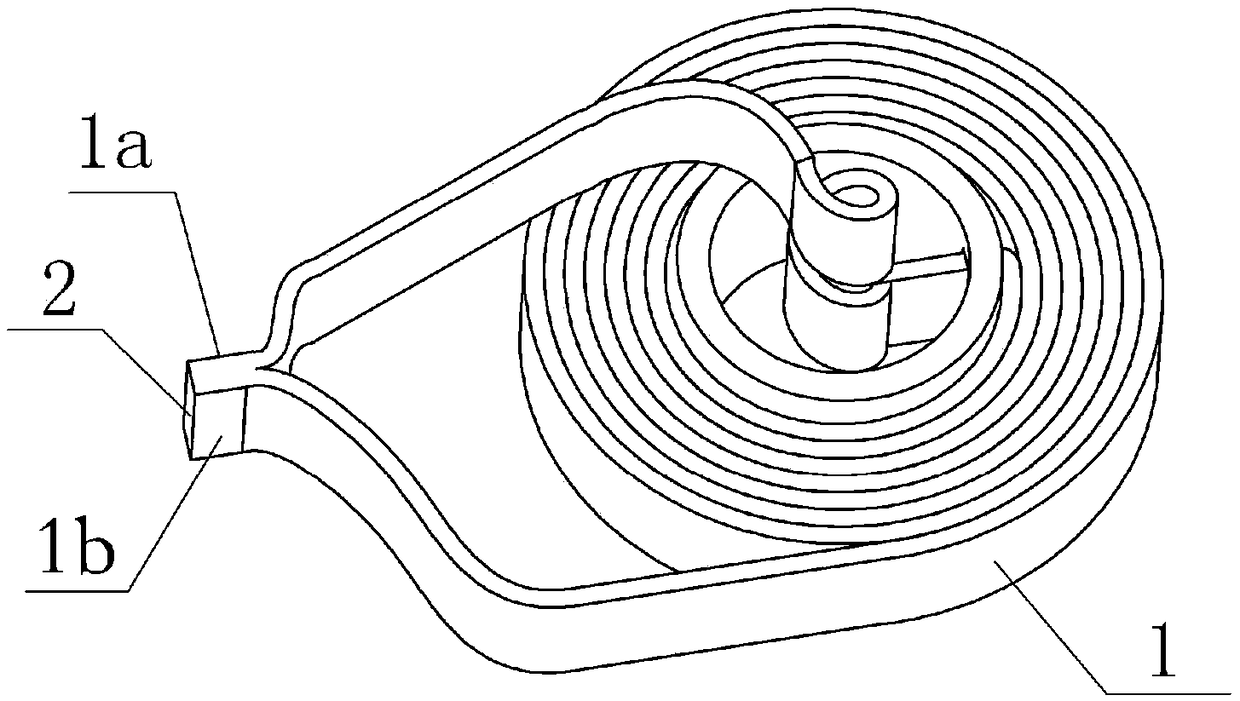

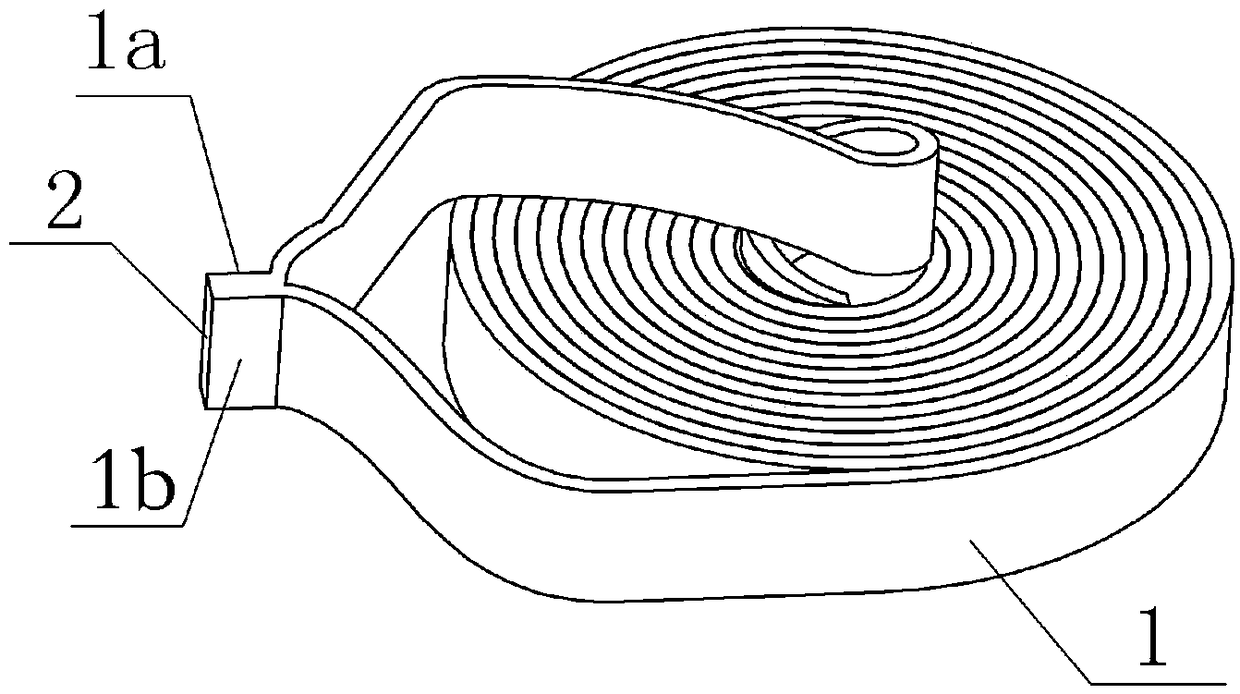

[0025] figure 1 Shown, the first kind of embodiment of the present invention is, a kind of manufacturing method of superconducting magnet for high-temperature superconducting maglev train, and its way is:

[0026] A. Coating curing agent on the surface of the high-temperature superconducting strip 1; while coating, the high-temperature superconducting strip 1 is wound from the inside to the outside to form a hollow ring or a solid round cake, and the strip 1 The inner end 1a of is exposed;

[0027] B. Connecting the inner end 1a of the high-temperature superconducting strip 1 and the outer end 1b of the high-temperature superconducting strip 1 to form a superconducting joint 2 to form a superconducting ring that is closed into a block.

[0028] Wherein, the specific method of connecting the inner end 1a of the high-temperature superconducting strip 1 and the outer end 1b of the high-temperature superconducting strip 1 to form a superconducting joint 2 is as follows:

[0029]...

Embodiment 2

[0034] figure 1 Show, a kind of manufacturing method of superconducting magnet for high-temperature superconducting maglev train, its way is:

[0035] A. Coating curing agent on the surface of the high-temperature superconducting strip 1; while coating, the high-temperature superconducting strip 1 is wound from the inside to the outside to form a hollow ring or a solid round cake, and the strip 1 The inner end 1a of is exposed;

[0036] B. Connecting the inner end 1a of the high-temperature superconducting strip 1 and the outer end 1b of the high-temperature superconducting strip 1 to form a superconducting joint 2 to form a superconducting cake that is closed into blocks.

[0037] Wherein, the specific method of connecting the inner end 1a of the high-temperature superconducting strip 1 and the outer end 1b of the high-temperature superconducting strip 1 to form a superconducting joint 2 is as follows:

[0038] B1. Peel off the protective layer: immerse the inner end 1a and...

Embodiment 3

[0043] A method for manufacturing a superconducting magnet for a high-temperature superconducting maglev train, comprising:

[0044] A. Coating curing agent on the surface of the high-temperature superconducting strip 1; while coating, the high-temperature superconducting strip 1 is wound from the inside to the outside to form a hollow ring or a solid round cake, and the strip 1 The inner end 1a of is exposed;

[0045] B. Connecting the inner end 1a of the high-temperature superconducting strip 1 and the outer end 1b of the high-temperature superconducting strip 1 to form a superconducting joint 2 to form a superconducting ring that is closed into a block.

[0046] Wherein, the specific method of connecting the inner end 1a of the high-temperature superconducting strip 1 and the outer end 1b of the high-temperature superconducting strip 1 to form a superconducting joint 2 is as follows:

[0047] B1. Peel off the protective layer: immerse the inner end 1a and outer end 1b of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| superconducting critical temperature | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com