Strain screening method with efficient desulfurization and denitrification activities simultaneously

A strain screening and denitrification technology, applied in the biological field, can solve the problems of increasing equipment and raw material input, increasing operating costs, etc., achieve the effects of lasting sulfide degradation activity and ammonia nitrogen degradation activity, reducing operating costs, and avoiding load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

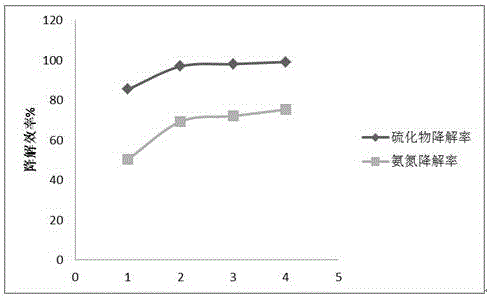

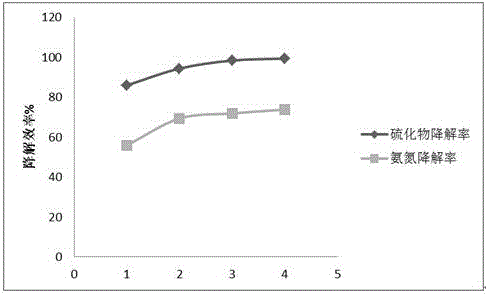

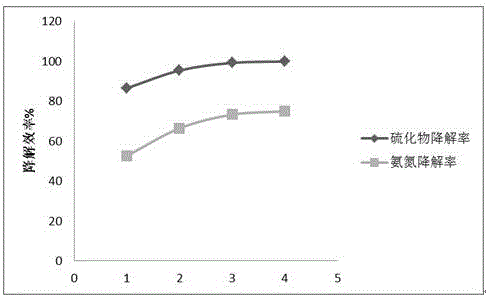

Image

Examples

Embodiment 1

[0030] The first screening procedure is as follows:

[0031] Take 20g of biochemical sludge from the ash yard of the power plant and put it into a petri dish filled with the primary screening medium, put the petri dish into a constant temperature shaker at 30°C for cultivation, keep the speed of the constant temperature shaker at 185 rpm, and the culture time is 5 days;

[0032] The primary screening medium consisted of 15g Na 2 S 2 o 3 , 9g KNO 3 , 6g (NH 4 )2HPO 4 , 1.5g MgCl 2 , 6g NaHCO 3 , 1.5g of cysteine, 30ml of vitamin nutrient solution and 30ml of trace element nutrient solution were mixed, adjusted to pH 7.0, and obtained after sterilizing at 121°C for 20 minutes;

[0033] The program of second step purification separation is:

[0034] Inoculate the strains in the petri dish after the first shaker culture to the solid medium, and place the solid medium inoculated with the strains in a biochemical incubator at 30°C for 3 days;

Embodiment 2

[0045] The first screening procedure is as follows:

[0046] Take 20g of biochemical activated sludge from Shaying Sewage Treatment Plant and put it into a petri dish filled with primary screening medium, put the petri dish into a constant temperature shaker at 30°C for cultivation, keep the speed of the constant temperature shaker at 185 rpm, and cultivate The time is 5 days;

[0047] The primary screening medium consisted of 15g Na 2 S 2 o 3 , 9g KNO 3 , 6g (NH 4 ) 2 HPO 4 , 1.5g MgCl 2 , 6g NaHCO 3 , 1.5g of cysteine, 30ml of vitamin nutrient solution and 30ml of trace element nutrient solution were mixed, adjusted to pH 7.0, and obtained after sterilizing at 121°C for 20 minutes;

[0048] The program of second step purification separation is:

[0049] Inoculate the strains in the petri dish after the first shaker culture to the solid medium, and place the solid medium inoculated with the strains in a biochemical incubator at 30°C for 3 days;

[0050] The solid m...

Embodiment 3

[0060] The first screening procedure is as follows:

[0061] Take 30g of activated sludge from the aeration tank of Zhuangxi Sewage Treatment Plant and put it into a petri dish filled with primary screening medium, put the petri dish into a constant temperature shaker at 30°C for cultivation, and keep the speed of the constant temperature shaker at 185 rpm min, the culture time is 5 days;

[0062] The primary screening medium consisted of 15g Na 2 S 2 o 3 , 9g KNO 3 , 6g (NH 4 ) 2 HPO 4 , 1.5g MgCl 2 , 6g NaHCO 3 , 1.5g of cysteine, 30ml of vitamin nutrient solution and 30ml of trace element nutrient solution were mixed, adjusted to pH 7.0, and obtained after sterilizing at 121°C for 20 minutes;

[0063] The program of second step purification separation is:

[0064] Inoculate the strains in the petri dish after the first shaker culture to the solid medium, and place the solid medium inoculated with the strains in a biochemical incubator at 30°C for 3 days;

[0065]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com