Building decoration waste derived fuel and method for preparing same

A garbage-derived fuel and construction technology, applied in the field of solid waste resource utilization, can solve the problem of no mature utilization of organic components, achieve high social and environmental benefits, and reduce the use of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 6kg of organic light component samples of construction and decoration waste sorted out by the sorting line into a shear crusher for 10 minutes, then add 2kg of coal powder and 0.5kg of quicklime in the mixer and mix for 10 minutes, then add 1.5kg of water-containing The river silt with a concentration of 50% is fully stirred for 5 minutes until the silt slurry fully wraps the light component fragments of decoration waste. Sampling was put into a metal test mold of Φ30mm×30mm, and the pressure was stabilized at 15KN for 5 minutes, and then the mold was removed to obtain a cylindrical construction and decoration waste-derived fuel.

[0027] Refer to GB / T 212-2008 "Measurement method for calorific value of coal" and use the automatic oxygen bomb calorimeter method to measure the calorific value of each component in the raw material and the calorific value of the fuel derived from construction and decoration waste, refer to GB / T 15459-2009 "Coal The method for measuring...

Embodiment 2

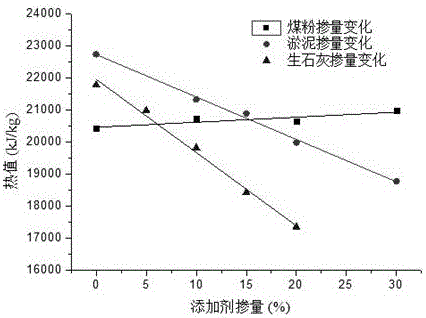

[0033] Select coal dust, silt and unslaked lime to be three kinds of additives as research object, take the proportioning described in embodiment 1 as benchmark proportioning (60wt% construction and decoration waste organic light component, 20wt% coal dust, 15wt% river course silt , 5wt% quicklime), using the raw materials and preparation process in Example 1 to prepare construction and decoration waste RDF with different additive ratios, and analyze the influence of each additive ratio change on the RDF calorific value.

[0034] Among them, the variation range of pulverized coal is 0%, 10%, 20%, 30%; the variation range of sludge is 0%, 10%, 15%, 20%, 30%, and the variation range of quicklime Set at 0%, 5%, 10%, 15%, 20%. When studying the influence law of specific additives, the dosage of other components shall be adjusted in equal proportions according to the initial ratio in the base ratio. The specific ratio is shown in Table 2.1, and the test results are as follows fig...

Embodiment 3

[0038] Taking the proportioning described in Example 1 as the benchmark proportioning (60wt% construction and decoration waste organic light components, 20wt% pulverized coal, 15wt% river silt, 5wt% quicklime), adjust the moisture content of the silt to 30% respectively , 50%, 70%, to test the mechanical strength of fuel derived from construction and decoration waste under different dosage conditions (0%, 5%, 10%, 15%, 20%, 25%, 30%). The experimental results are as figure 2 shown.

[0039] The change of the moisture content of the sludge has a significant impact on the adhesiveness of the sludge. If the moisture content is too low, the sludge will be dry and hard. If the moisture content is too high, the fluidity of the sludge will be too large. Both situations are not conducive to adhesion. Sexual play.

[0040]When the amount of silt is below 25% and the amount is the same, the mechanical strength of RDF mixed with 50% water content silt is higher than that of RDF mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com