Biogas slurry efficient solid-liquid separation treatment method for inducing protein salting-out precipitation

A protein salt, solid-liquid separation technology, used in flocculation/sedimentation water/sewage treatment, sludge treatment, water/sewage treatment, etc. Equipment corrosion and other problems, to achieve the effect of achieving the effect of water treatment, reducing the risk of secondary environmental pollution, and high social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

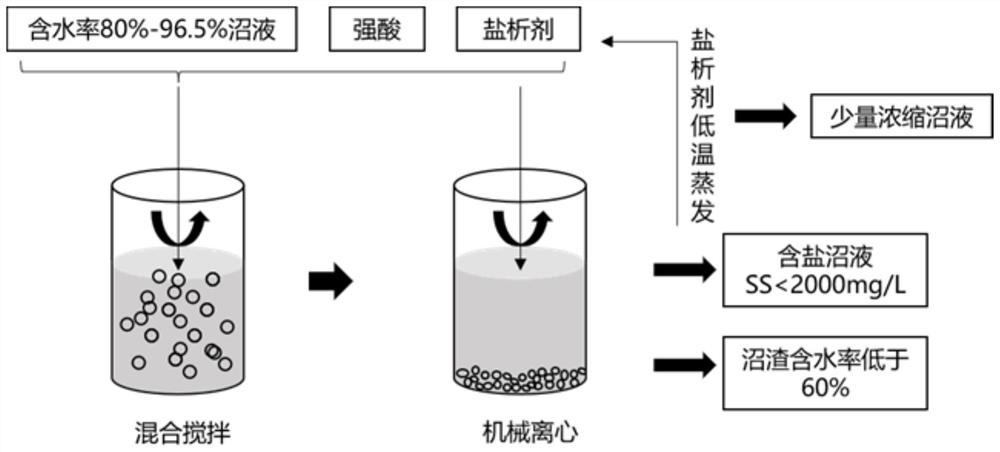

Method used

Image

Examples

Embodiment 1

[0051] Efficient solid-liquid separation treatment of biogas slurry in a kitchen waste treatment plant in Shanghai, including the following steps:

[0052] 1) Mix biogas slurry with an initial moisture content of 95.5% (SS is 15789mg / L, COD is 14200mg / L, BOD is 5723mg / L) and hydrochloric acid (5mol / L) at a mass ratio of 1:0.01 and stir for 5 minutes to obtain a mixed solution ;

[0053] 2) Add a mass fraction of 60% ammonium sulfate solution to the mixed solution, and mix and stir for 5 minutes; wherein, the mixing mass ratio of the mixed solution to the ammonium sulfate solution is 1:0.04;

[0054] 3) The solid-liquid separation is carried out by mechanical centrifugation, the centrifugal speed is 2000rpm, and the centrifugation time is 1min;

[0055] 4) The salting-out agent is evaporated and recovered from the supernatant after centrifugation at low temperature, the operating temperature is 30°C, the vacuum degree is 0.001MPa, and the condensation temperature of the solven...

Embodiment 2

[0058] Efficient solid-liquid separation treatment of biogas slurry in a kitchen waste treatment plant in Shanghai, including the following steps:

[0059] 1) Mix biogas slurry with an initial moisture content of 85.5% (SS is 14723mg / L, COD is 11300mg / L, BOD is 4956mg / L) and hydrochloric acid (5mol / L) at a mass ratio of 1:0.01 and stir for 8 minutes to obtain a mixed solution ;

[0060] 2) adding mass fraction to the mixed solution is 70% ammonium sulfate solution, and mixed and stirred for 5min; wherein, the mixing mass ratio of the mixed solution to the ammonium sulfate solution is 1:0.06,

[0061] 3) The solid-liquid separation is carried out by mechanical centrifugation, the centrifugal speed is 2750rpm, and the centrifugation time is 2min;

[0062] 4) The salting-out agent is evaporated and recovered from the supernatant after centrifugation at low temperature, the operating temperature is 35°C, the vacuum degree is 0.002MPa, and the solvent vapor condensation temperatur...

Embodiment 3

[0065] Efficient solid-liquid separation treatment of biogas slurry in a kitchen waste treatment plant in Shanghai, including the following steps:

[0066] 1) Mix biogas slurry with an initial moisture content of 91.5% (SS is 14378mg / L, COD is 12100mg / L, BOD is 4516mg / L) and hydrochloric acid (5mol / L) at a mass ratio of 1:0.02 and stir for 10 minutes to obtain a mixed solution ;

[0067] 2) Adding a mass fraction of 70% ammonium sulfate solution to the mixed solution, and mixing and stirring for 10 min; wherein, the mixing mass ratio of the mixed solution to the ammonium sulfate solution is 1:0.06,

[0068] 3) The solid-liquid separation is carried out by mechanical centrifugation, the centrifugal speed is 3400rpm, and the centrifugation time is 1min;

[0069] 4) The salting-out agent is recovered by low-temperature evaporation from the supernatant after centrifugation, the operating temperature is 40°C, the vacuum is 0.002MPa, and the solvent vapor condensation temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com