Technology and kiln for producing calcium magnesium phosphate and potassium fertilizer by using yellow phosphorus tail gas as fuel with kiln method

A yellow phosphorus tail gas, calcium magnesium phosphorus technology, applied in potash fertilizers, combustion methods, furnaces and other directions, can solve the problems of high production cost, high labor intensity, serious pollution, etc., and achieve the goal of improving utilization, reducing energy waste and reducing pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

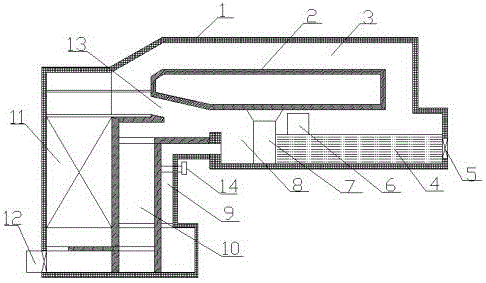

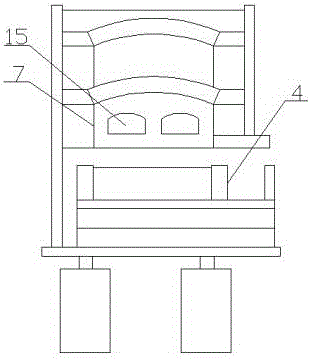

[0026] Embodiment of the present invention: a kind of yellow phosphorus tail gas is fuel, the kiln that kiln method produces calcium magnesium phosphorus, potash fertilizer, as attached Figure 1-2 As shown, a combustion chamber 8 is included, and one side of the combustion chamber 8 is connected with an exhaust gas intake channel 9 and an oxygen-enhancing channel 10, and the intake ports of the exhaust gas intake channel 9 and the oxygen-enhancing channel 10 are respectively connected to the yellow phosphorus exhaust gas transportation pipeline and The oxygen-enhancing gas transportation pipeline, the other side of the combustion chamber 8 is provided with a melting chamber 1, the bottom of the melting chamber 1 is provided with a melting pool 4, the melting pool 4 contains ore raw materials, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com