Amorphous manganite/graphite composite nano material and preparation method and application thereof to lithium ion battery

A composite nanomaterial, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of material capacity decay, poor conductivity of manganese oxides, poor rate performance, etc., to achieve inhibition of agglomeration, low price , the effect of good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take by weighing 0.75g graphite successively, 14.25g potassium permanganate, 75g zirconium ball (grinding medium), add in the ball mill jar, then add 50ml water wherein, add sealing ring, react 48h under 400rpm, the sample that obtains is passed through After the zirconium balls were filtered out through a sieve and sonicated for 2 hours, they were centrifuged and washed 4 times with distilled water, and dried at 60° C. for 12 hours to obtain an amorphous manganese oxide / graphite composite nanomaterial.

[0037] Weigh 0.2g of the amorphous manganese oxide / graphite composite nanomaterial prepared in this example, 0.025g of PVDF, and 0.025g of carbon black, mix and grind them and transfer them to a small glass bottle, add 1ml of NMP, and stir magnetically for 4 hours. The materials were coated on copper foil to make electrodes, and metal lithium was used as the counter electrode to assemble CR2016 button batteries in the glove box, and the electrochemical performance tests...

Embodiment 2

[0039] Weigh 1.5g of graphite, 13.5g of potassium permanganate, and 75g of zirconium balls (grinding medium) in turn, add them to the ball mill jar, add 50ml of water to it, add a sealing ring, react at 400rpm for 48h, and sieve the obtained sample After the zirconium balls were filtered out through a net and ultrasonicated for 2 hours, they were centrifuged and washed 4 times with distilled water, and dried at 60° C. for 12 hours to obtain an amorphous manganese oxide / graphite composite nanomaterial.

[0040] Weigh 0.2g of the amorphous manganese oxide / graphite composite nanomaterial prepared in this example, 0.025g of PVDF, and 0.025g of carbon black, mix and grind them and transfer them to a small glass bottle, add 1ml of NMP, and stir magnetically for 4 hours. The materials were coated on copper foil to make electrodes, and metal lithium was used as the counter electrode to assemble CR2016 button batteries in the glove box, and the electrochemical performance tests were car...

Embodiment 3

[0042] Weigh successively 4.5g of graphite, 10.5g of potassium permanganate, and 75g of zirconium balls (grinding medium), add them to the ball mill jar, then add 50ml of water, add a sealing ring, react at 400rpm for 48h, and sieve the obtained sample After the zirconium balls were filtered out through a net and ultrasonicated for 2 hours, they were centrifuged and washed 4 times with distilled water, and dried at 60° C. for 12 hours to obtain an amorphous manganese oxide / graphite composite nanomaterial.

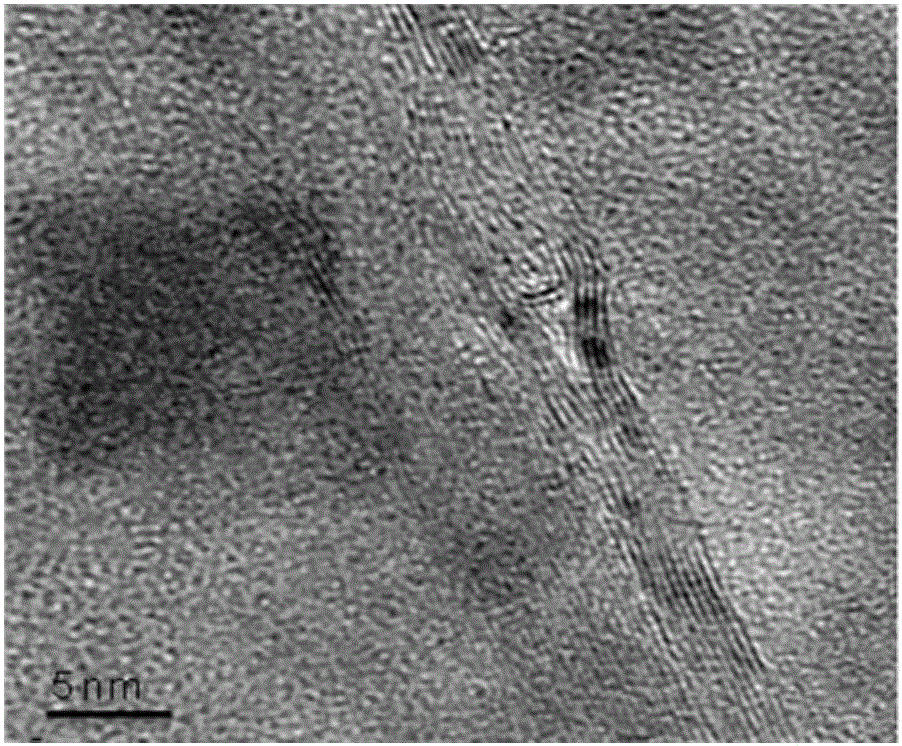

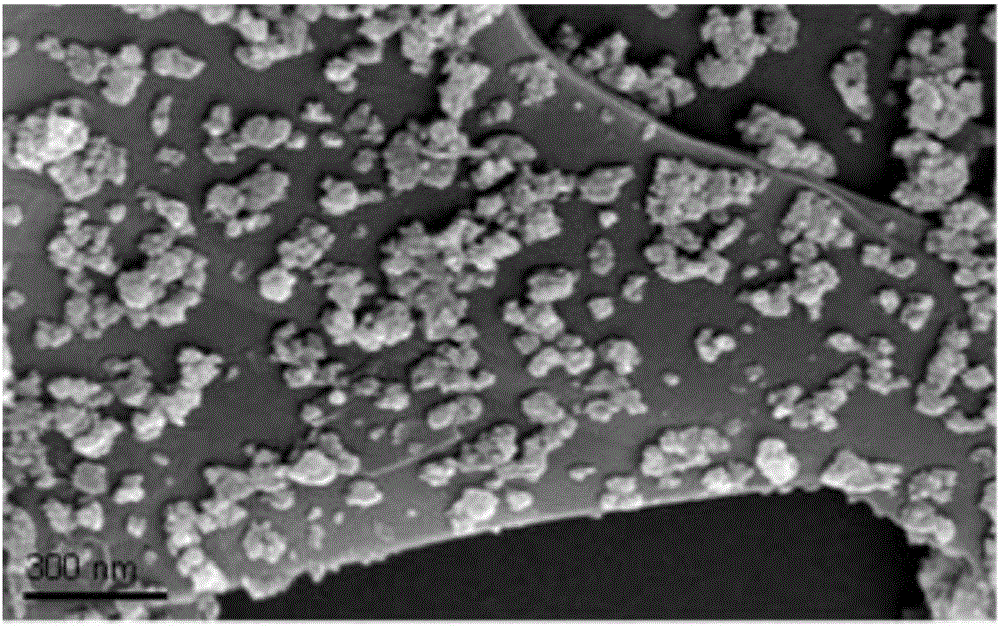

[0043] The TEM images of the amorphous manganese oxide / graphite composite nanomaterials prepared in this embodiment under different magnifications are as follows figure 1 , figure 2 Shown, as seen from the figure, the present invention adopts simple ball milling method, utilizes the strong oxidation of mechanical force and potassium permanganate, successfully strips natural graphite into graphite (10~15 layers) of few layers.

[0044] Weigh 0.2g of the amorphous manganese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com