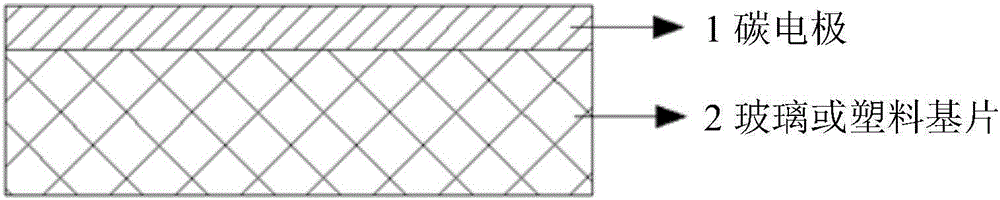

Ink printing process-based preparation method of carbon electrode

A carbon electrode and process technology, applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problems of carbon electrode complicated steps, high preparation temperature, high preparation cost, etc., to reduce production steps and complexity , carbon electrode performance improvement, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

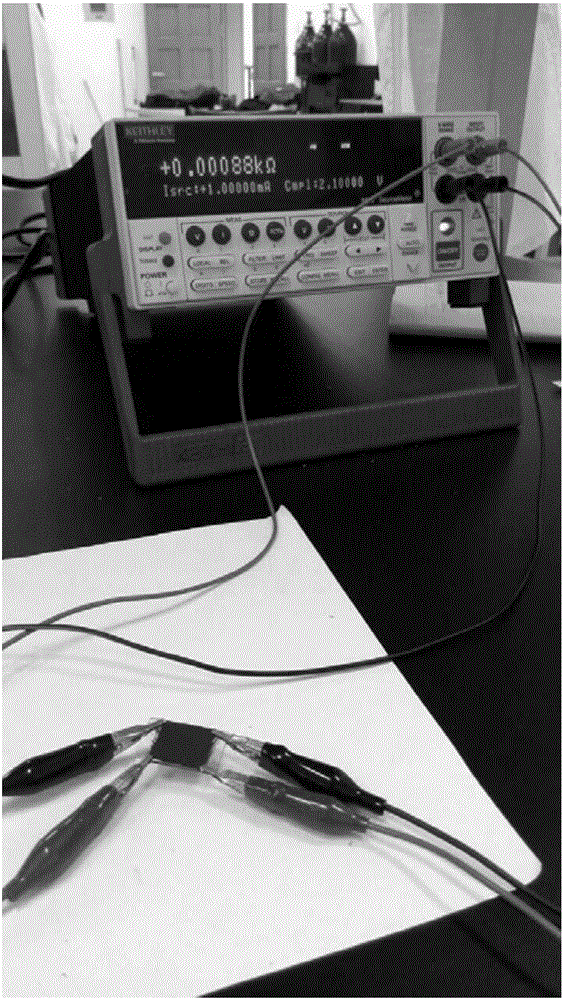

[0038] A method for preparing a carbon electrode based on an ink printing process, characterized in that it comprises the following steps:

[0039] 1) Cleaning of the glass substrate

[0040] Number the 7.5×2.5cm glass substrates, rinse both sides of the slides with water, and apply a small amount of detergent on both sides of the slides. Then rinse with water until there is no detergent on the surface, and rinse both sides of the slide with deionized water. Finally, rinse the slides with IPA (isopropanol), and place the slides in a constant temperature drying oven at 60 degrees for later use.

[0041] 2) Preparation of conductive carbon paste

[0042] 2.1) Use an electronic balance to take a certain amount of chloroplatinic acid and put it into the reagent bottle.

[0043] 2.2) Use an electronic balance to take a certain amount of conductive carbon black and conductive graphite powder and put them into the above reagent bottle, wherein conductive carbon black: conductive g...

Embodiment 2

[0057] A method for preparing a carbon electrode based on an ink printing process, characterized in that it comprises the following steps:

[0058] 1) Cleaning of the glass substrate

[0059] Number the 7.5×2.5cm glass substrates, rinse both sides of the slides with water, and apply a small amount of detergent on both sides of the slides. Then rinse with water until there is no detergent on the surface, and rinse both sides of the slide with deionized water. Finally, rinse the slides with IPA (isopropanol), and place the slides in a constant temperature drying oven at 60 degrees for later use.

[0060] 2) Preparation of conductive carbon paste

[0061] 2.1) Use an electronic balance to take a certain amount of chloroplatinic acid and put it into the reagent bottle.

[0062] 2.2) Use an electronic balance to take a certain amount of carbon nanotubes, conductive graphite powder and conductive carbon black into the above reagent bottle, wherein carbon black:graphite:carbon nan...

Embodiment 3

[0076] A method for preparing a carbon electrode based on an ink printing process, characterized in that it comprises the following steps:

[0077] 1) Cleaning of the glass substrate

[0078] Number the 7.5×2.5cm glass substrates, rinse both sides of the slides with water, and apply a small amount of detergent on both sides of the slides. Then rinse with water until there is no detergent on the surface, and rinse both sides of the slide with deionized water. Finally, rinse the slides with IPA (isopropanol), and place the slides in a constant temperature drying oven at 60 degrees for later use.

[0079] 2) Preparation of conductive carbon paste

[0080] 2.1) Use an electronic balance to take a certain amount of chloroplatinic acid and put it into the reagent bottle.

[0081] 2.2) Use an electronic balance to take a certain amount of conductive carbon black and conductive graphite powder and put them into the above reagent bottle, wherein conductive carbon black: conductive g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com