Method for increasing coal bed gas yield through indigenous bacteria

A technology of coalbed methane and native bacteria, which is applied in the preparation of test samples, bacteria, earth square drilling, etc., can solve the problems of high energy consumption, low work efficiency, and long processing time, so as to improve the coal seam structure and enhance efficiency , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

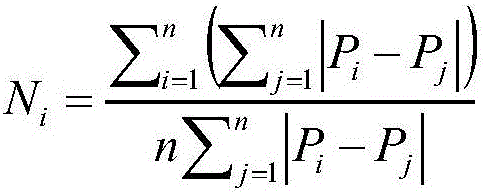

Method used

Image

Examples

Embodiment 1

[0039] A kind of method that utilizes native bacterium to improve coalbed methane output provided by the invention, the steps are as follows:

[0040] (1) The target coalbed methane field is a certain area in the south of the Junggar Basin in Xinjiang. Coal samples from coalbed methane reservoirs are collected, and samples are taken at the wellhead of the coalbed methane. The sample bottles are pre-sterilized and filled with nitrogen. The air remains, and it is sent into the anaerobic incubator in a shading manner within 24 hours; the colony structure is extracted from the coal sample and water sample, and the microbial community structure of the coal sample and water sample is analyzed by cloning library technology For analysis, the bacterial species were quantitatively analyzed by qPCR technology.

[0041] The target coal seam for CBM development is the coal seam of the Xishanyao Formation in the Middle Jurassic, with a reservoir pressure of 3.8MPa, a reservoir temperature o...

Embodiment 2

[0074] On the basis of the foregoing embodiment, the optimal parameters obtained in the step (5) are: the optimal parameter pressure of the ultrasonic treatment is 0.8Mpa, the ultrasonic frequency is 80kHz, the processing time is 20min, and the supercritical CO 2The optimal parameter pressure for processing is 8.2MPa, and the processing time is 30h. Under this condition, the ultrasonic coupling supercritical CO 2 The amount of methane produced by biodegradation per unit mass of coal after treatment is the largest.

[0075] The gas composition and methane concentration change at the gas production port in the step (9) are measured by a methane analyzer and a gas chromatograph.

Embodiment 3

[0077] On the basis of the above-mentioned embodiments, in the step (2), each bacterial strain combination is added with anaerobic fermentation bacteria to enhance the degradation degree of coal, and determine the most favorable bacterial colony combination for gas production in the target coal seam through the collocation of different combinations, and at the same time Avoid inhibition between colonies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com