Novel high-performance dyeing carrier composition and application thereof

A high-performance, dye-introducing agent technology, which is applied in the field of textile printing and dyeing auxiliaries, can solve the problems of prone to color blooms and high requirements for dye-introducing agents, and achieve good washing fastness and high rubbing fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

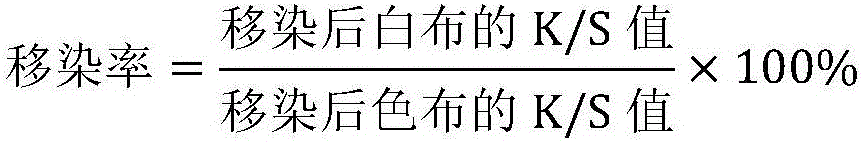

Method used

Image

Examples

preparation example Construction

[0041] The preparation methods of the dibenzyl ether described in the present invention are those well known to those skilled in the art. Specific preparation methods can be listed, for example: it is prepared by the action of benzyl chloride and concentrated alkali, which is also a by-product during the production of benzyl alcohol, and it can also be prepared from benzyl alcohol through etherification.

[0042]Dibenzyl ether often contains impurities such as benzaldehyde and toluene. Its purification method includes, for example, sufficient washing with sodium hydroxide solution and sodium bisulfite solution to remove benzaldehyde. After drying over potassium carbonate, toluene was removed by fractional distillation under reduced pressure. Distillation is carried out in a nitrogen or carbon dioxide stream. It can also be refined by crystallization.

[0043] Based on 100 parts by weight of the nonionic surfactant, the dibenzyl ether is 1-10 parts.

[0044] polystyrene s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com