1120 alloy aluminum foil of flexible sticky ceramic welding backing and production method thereof

A ceramic welding and pasting technology, which is applied in the field of aluminum foil processing, can solve problems such as warping and easy falling off that cannot meet the requirements for the stable and non-moving use of ceramic welding pads, and achieve the reduction of lattice defects and the improvement of flexibility , The effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

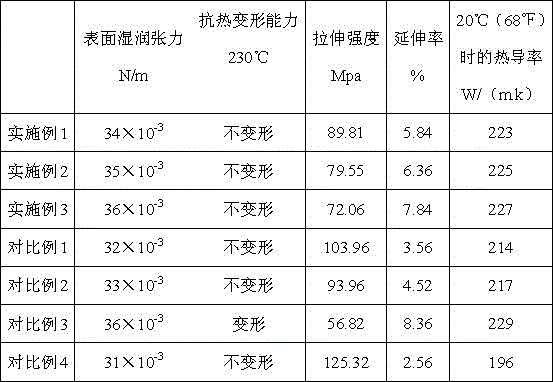

Examples

Embodiment 1

[0038] A kind of 1120 alloy flexible pasting type ceramic welding liner aluminum foil, the 1120 alloy flexible pasting type ceramic welding liner aluminum foil contains 0.20wt% iron, 0.10wt% silicon, 0.40wt% copper, 0.006wt% magnesium, 0.008 Wt% manganese, 0.003wt% zinc, 0.01wt% titanium, individual content of unremovable impurities < 0.03wt%, total content of unremovable impurities < 0.10wt%, and the rest is aluminum.

[0039] A kind of processing technology of 1120 alloy flexible paste type ceramic welding liner aluminum foil, its technology comprises following processing steps:

[0040] The first step: batching, the raw materials are configured according to the proportioning ratio described in claim 1;

[0041] The second step: smelting. After the prepared charge is melted and the slag is removed, when the melt temperature reaches 740~760°C, the copper element is directly evenly dispersed and thrown into the aluminum molten pool in the form of metal additives, and then stir...

Embodiment 2

[0056] A kind of 1120 alloy flexible pasting type ceramic welding backing aluminum foil, the 1120 alloy flexible pasting type ceramic welding backing aluminum foil contains 0.15wt% iron, 0.07wt% silicon, 0.30wt% copper, 0.003wt% magnesium, 0.003 Wt% manganese, 0.004wt% zinc, 0.016wt% titanium, individual content of non-removable impurities < 0.03wt%, total content of non-removable impurities < 0.10wt%, and the rest is aluminum.

[0057] A kind of processing technology of 1120 alloy flexible paste type ceramic welding liner aluminum foil, its technology comprises

[0058] The following processing steps:

[0059] The first step: batching, the raw materials are configured according to the proportioning ratio described in claim 1;

[0060] The second step: smelting. After the prepared charge is melted and the slag is removed, when the melt temperature reaches 740~760°C, the copper element is directly evenly dispersed and thrown into the aluminum molten pool in the form of metal a...

Embodiment 3

[0075] A kind of 1120 alloy flexible pasting type ceramic welding liner aluminum foil, the 1120 alloy flexible pasting type ceramic welding liner aluminum foil contains 0.10wt% iron, 0.04wt% silicon, 0.20wt% copper, 0.002wt% magnesium, 0.004 Wt% manganese, 0.003wt% zinc, 0.03wt% titanium, individual content of non-removable impurities < 0.03wt%, total content of non-removable impurities < 0.10wt%, and the rest is aluminum.

[0076] A kind of processing technology of 1120 alloy flexible paste type ceramic welding liner aluminum foil, its technology comprises following processing steps:

[0077] The first step: batching, the raw materials are configured according to the proportioning ratio described in claim 1;

[0078] The second step: smelting. After the prepared charge is melted and the slag is removed, when the melt temperature reaches 740~760°C, the copper element is directly evenly dispersed and thrown into the aluminum molten pool in the form of metal additives, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com