Polyaspartic-acid-containing architectural retarder and preparation method thereof

A polyaspartic acid, construction technology, applied in the field of construction retarders, can solve the problems of concrete segregation and bleeding, mildew of concrete water reducer, affecting the storage time of concrete water reducer, etc., and achieves significant progress, The effect of highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

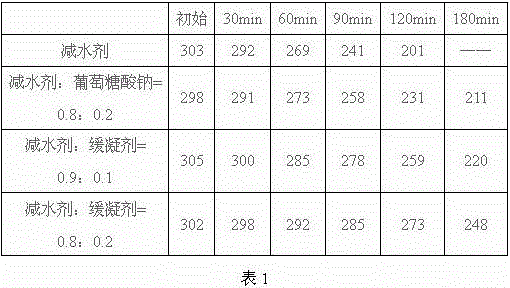

Examples

preparation example Construction

[0023] In the first aspect, the present invention provides a method for preparing a construction retarder containing polyaspartic acid, comprising the following steps:

[0024] (1) In the present invention, polyaspartic acid and unsaturated alcohol compounds are esterified under acidic catalytic conditions to synthesize polymer molecules with copolymerization reaction.

[0025] Fully dissolve polyaspartic acid in unsaturated alcohol compounds, mechanically stir at room temperature, and feed HCl gas, and add polymerization inhibitor. Stir the reaction for 30min~120min, then heat and reflux for 30min~60min, and evaporate the water and excess unsaturated enol compounds generated by the reaction under reduced pressure to obtain a polyaspartic acid compound containing unsaturated double bonds.

[0026] (2) Mechanically mix the polyaspartic acid compound containing unsaturated double bond structure synthesized in step (1) with unsaturated carboxylic acid and unsaturated sulfonic aci...

Embodiment 1

[0029] Fully dissolve 3000g of polyaspartic acid with a number average molecular weight of 3000 in 60g of acrylic acid, mechanically stir at room temperature, continuously feed HCl gas at a rate of 100ml / min, add 0.5g of hydroquinone as Polymerization inhibitor. Stir the reaction for 60 minutes, heat and reflux for 45 minutes at 70°C, evaporate the water and excess propenyl alcohol generated by the reaction under reduced pressure at 0.2 times the standard atmospheric pressure and 70°C to obtain polyaspartic acid containing unsaturated double bonds compound.

[0030] Mechanically mix 1000g of the polyaspartic acid compound containing unsaturated double bond structure synthesized above with 150g of methacrylic acid and 50g of sodium methacrylate sulfonate, and add 20g of ammonium persulfate as an initiator. carry out the copolymerization reaction. After the reaction, deionized water was added to adjust the reactant concentration to 30%.

Embodiment 2

[0032] Fully dissolve 4000g of polyaspartic acid with a number average molecular weight of 4000 in 65g of methacrylic acid, mechanically stir at room temperature, continuously feed HCl gas at a rate of 80ml / min, add 0.5g of terephthalic acid Phenol as a polymerization inhibitor. Stir the reaction for 70 minutes, heat and reflux at 65°C for 50 minutes, and evaporate the water and excess methacryl alcohol generated by the reaction under reduced pressure at 0.2 times the standard atmospheric pressure and 75°C to obtain polyaspartic acid containing unsaturated double bonds. amino acid compound.

[0033] Mechanically mix 1000g of polyaspartic acid compound containing unsaturated double bond structure synthesized above with 120g of methacrylic acid and 40g of sodium propylene sulfonate, add 25g of sodium persulfate as an initiator, and carry out copolymerization at 60°C reaction. After the reaction, deionized water was added to adjust the reactant concentration to 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com