Pyramidal silicon carbide ceramic absorber and preparation method thereof

A technology of conical silicon carbide and absorber, applied in the field of functional materials, to achieve the effects of improved electrical performance, large economic value, and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

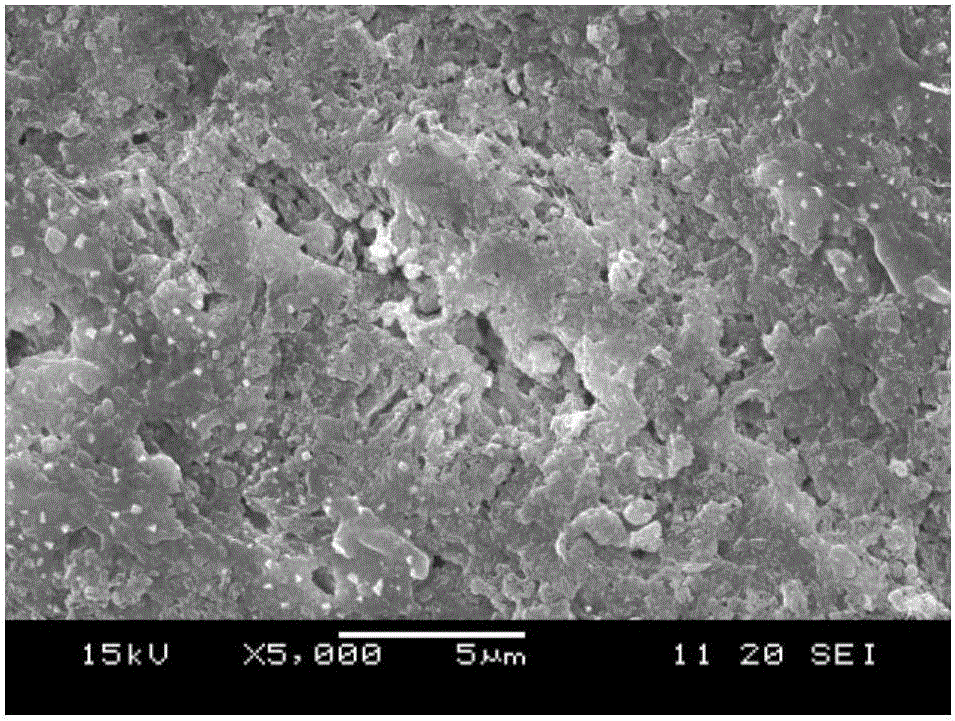

Image

Examples

Embodiment 1

[0036] Example 1: Preparation and performance test of a tapered silicon carbide ceramic absorber.

[0037] a) Weigh various components according to the following weight percentages: 55% SiC, 7% SiO 2 , 18% MgO, 3% BaCO 3 , 0.5% MnO 2 , 0.8% CoO, 1% V 2 O 5 , 1.2% Al 2 O 3 , 10% semi-refined paraffin, 3.5% low-density polyethylene particles, and mix the above components in a mixer at a temperature of 100°C, a rotation speed of 30 rpm, and a time of 3 hours. When the material is discharged, it is a block with uniform color;

[0038] b) placing the mixture obtained in step a) in a pulverizer to obtain pellets with a particle size of 2 to 4 mm;

[0039] c) Place the pellets obtained in step b) in the barrel of the injection molding machine for injection molding, the injection temperature is 150° C., the molding pressure is 10 MPa, and the green body is demolded and cooled to room temperature to obtain a ceramic green body;

[0040] d) Put the ceramic green body obtained in step c) in a ga...

Embodiment 2

[0044] Example 2: Preparation and performance test of a tapered silicon carbide ceramic absorber.

[0045] a) Weigh various components according to the following weight percentages: 60% SiC, 5% SiO 2 , 15% MgO, 3% BaCO 3 , 0.5% MnO 2 , 0.8% CoO, 1% V 2 O 5 , 1.2% Al 2 O 3 , 10% semi-refined paraffin, 3.5% low-density polyethylene particles, and mix the above components in a mixer at a temperature of 100°C, a rotation speed of 30 rpm, and a time of 2 hours. When the material is discharged, it is a block with uniform color;

[0046] b) Place the block obtained in step a) in a pulverizer to obtain granular material with a particle size of 2 to 4 mm;

[0047] c) placing the pellets obtained in step b) in the barrel of an injection molding machine for injection molding, the injection molding machine has an injection temperature of 150° C., a molding pressure of 10 MPa, and the green body is demolded and cooled to room temperature to obtain a ceramic green body;

[0048] d) Put the ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com