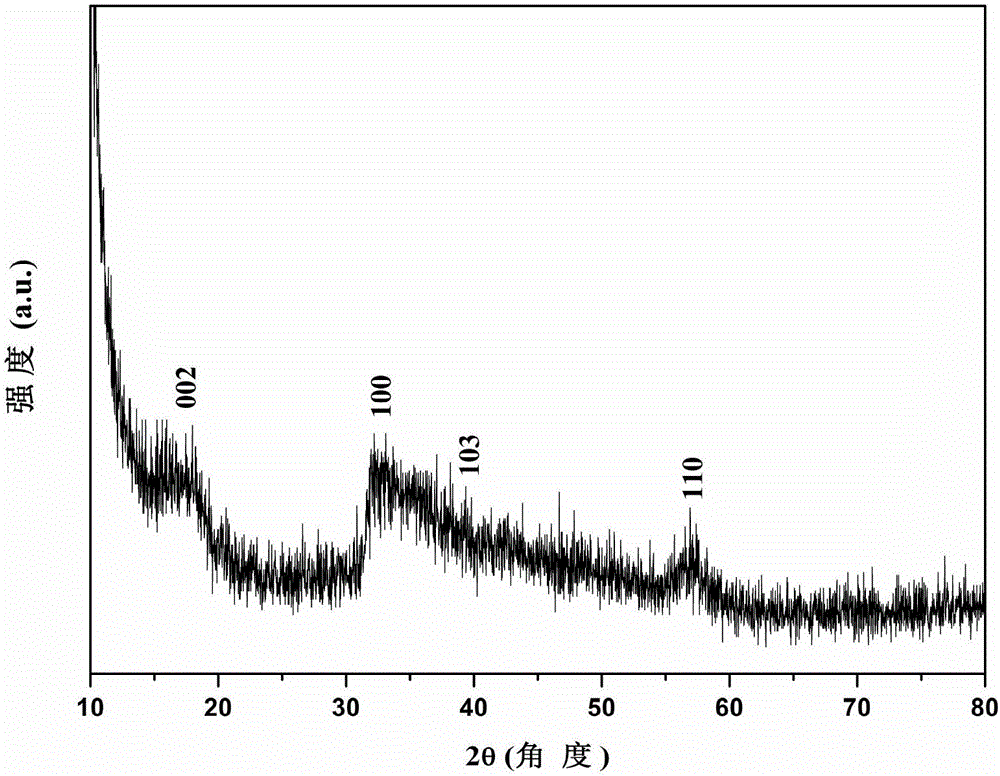

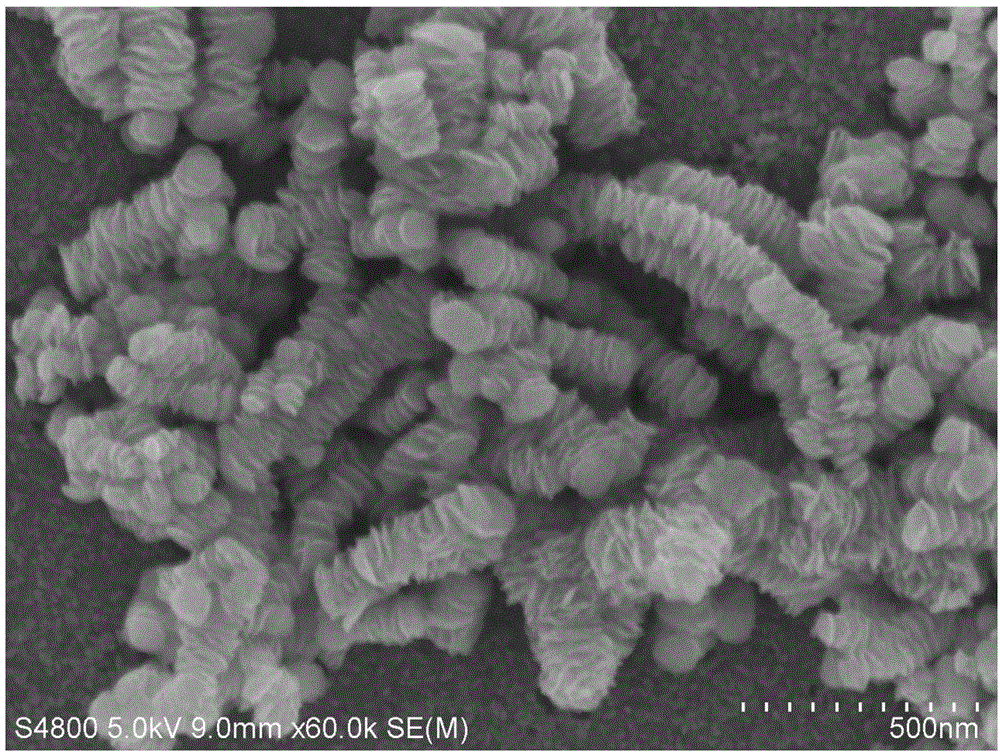

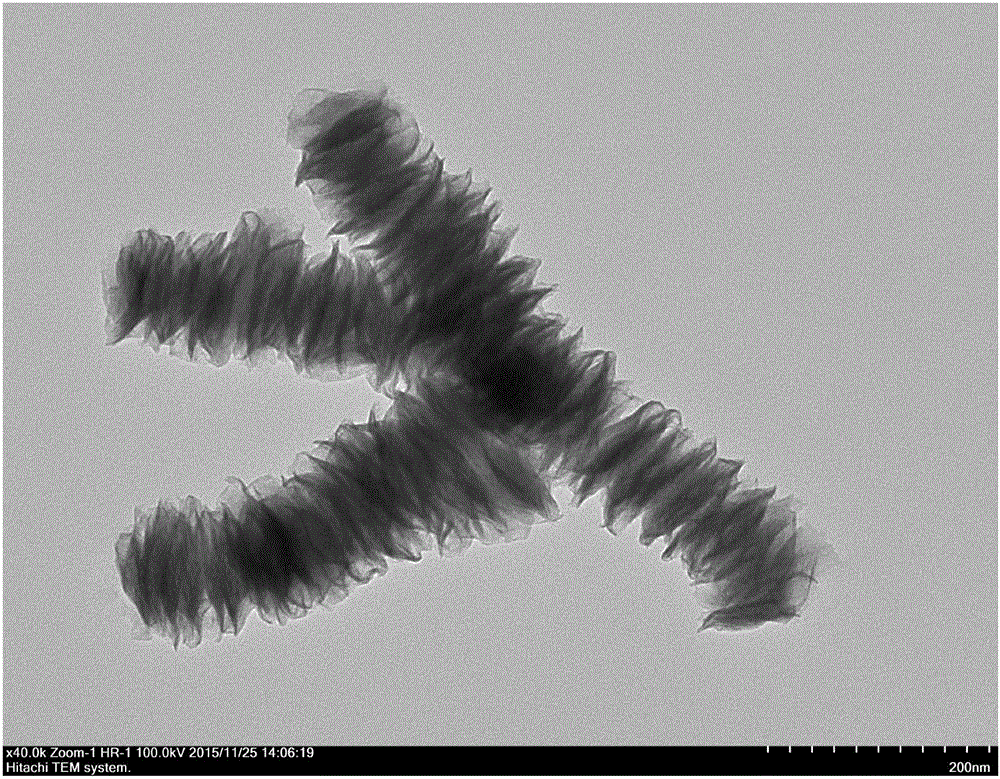

Lamella accumulated one-dimensional molybdenum disulfide nanometer material and preparation method thereof

A technology of molybdenum disulfide and nanomaterials, which is applied in the direction of molybdenum sulfide, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high price, unfavorable large-scale production, limited reserves of Pt group precious metals, etc., and achieve low cost, Good electrocatalytic activity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of the one-dimensional molybdenum disulfide nanometer material of lamellar stacking, comprises the following steps:

[0036] A, add 0.022g sodium molybdate crystal (Na 2 MoO 4 2H 2 (2), 0.0083g thioglycolic acid, make the atomic molar ratio of Mo and S in sodium molybdate and thioglycolic acid meet 1:1, the concentration of Mo in ultrapure water is controlled at 3mmol / L, obtains mixed solution A, with a volume of 30 mL.

[0037] B. Add 0.5 mL of ammonia water with a mass concentration of 25-28% to the A solution obtained in step 1, stir, and adjust the pH to 11-12 to obtain a mixed solution B;

[0038] C. Transfer the mixed solution B into a polytetrafluoroethylene-lined reaction kettle, place the reaction kettle in a constant temperature box, the reaction temperature is 220°C, and after constant temperature for 18 hours, cool to room temperature;

[0039] D. Centrifuge the solid product in the reaction kettle, wash and centrifuge with e...

Embodiment 2

[0044] A kind of preparation method of the one-dimensional molybdenum disulfide nanometer material of lamellar stacking, comprises the following steps:

[0045] A. Add 0.022g sodium molybdate crystals to ultrapure water, add 0.0166g thioglycolic acid after dissolving, so that the atomic molar ratio of Mo and S in sodium molybdate and thioglycolic acid satisfies 1:2, Mo atoms The concentration in ultrapure water was controlled at 3 mmol / L to obtain mixed solution A with a volume of 30 mL.

[0046] B. Add 0.5 mL of ammonia water with a mass concentration of 25-28% to the A solution obtained in step 1, stir, and adjust the pH to 11-12 to obtain a mixed solution B;

[0047] C. Transfer the mixed solution B into a polytetrafluoroethylene-lined reaction kettle, place the reaction kettle in a thermostat with a reaction temperature of 220°C, keep the temperature for 18 hours, and then cool to room temperature.

[0048] D. Centrifuge the solid product in the reaction kettle, wash and ...

Embodiment 3

[0051] A kind of preparation method of the one-dimensional molybdenum disulfide nanometer material of lamellar stacking, comprises the following steps:

[0052] A. Add 0.029g sodium molybdate crystals and 0.0166g thioglycolic acid in ultrapure water, so that the atomic molar ratio of Mo and S in sodium molybdate and thioglycolic acid meets 1:2, and the Mo atom is in the ultrapure The concentration in water was controlled at 4 mmol / L to obtain mixed solution A with a volume of 30 mL.

[0053] B. Add 1 mL of ammonia water with a mass concentration of 25-28% to the A solution obtained in step 1, stir, and adjust the pH to 11-12 to obtain a mixed solution B;

[0054] C. Transfer the mixed solution B into a polytetrafluoroethylene-lined reaction kettle, place the reaction kettle in a thermostat with a reaction temperature of 180°C, keep the temperature constant for 24 hours, and then cool to room temperature.

[0055] D. Centrifuge the solid product in the reaction kettle, wash an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com