Post-carburization surface strengthening method for low-carbon steel part

A surface-strengthening, low-carbon steel technology, used in explosion generating devices, abrasives, metal processing equipment, etc., can solve the problems of increased surface roughness, high cost, difficult to achieve residual compressive stress, etc., to reduce the surface roughness value, The effect of improved workpiece fatigue performance and small surface roughness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

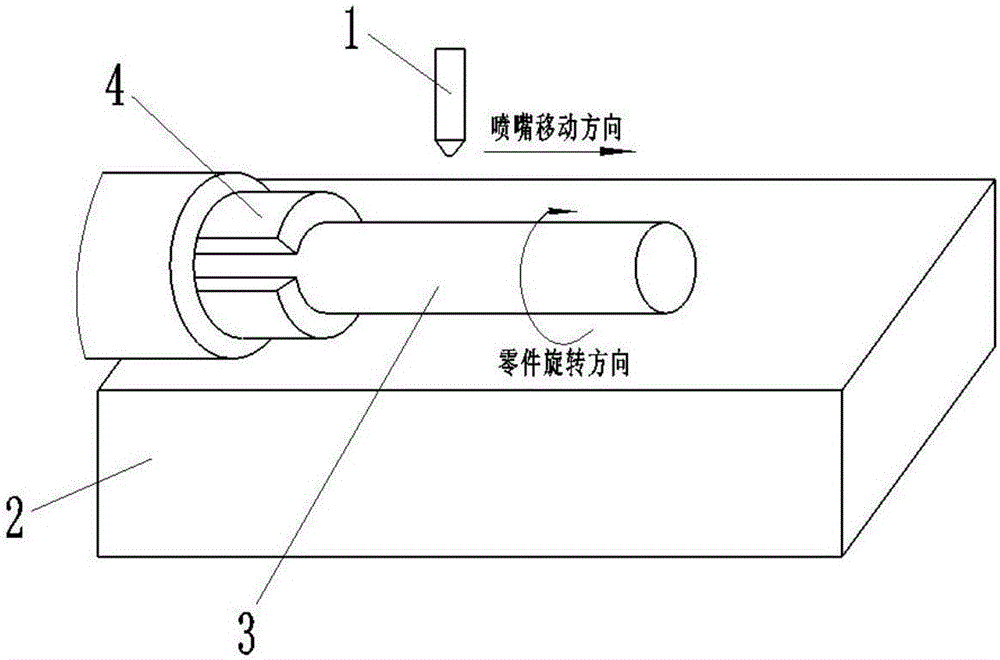

[0015] The workpiece to be sprayed in this embodiment is a round low-carbon steel part after carburizing. see figure 1 Firstly, the circular workpiece 3 is fixed by the chuck 4 and driven to rotate at a speed of 30r / min, and then the surface of the circular workpiece 3 is strengthened by means of ultra-high pressure numerical control water jet, that is, the mixed abrasive is produced by its own weight and high-speed water flow. The negative pressure makes the mixed abrasive enter the mixing tube and mix with water, and the mixed abrasive is sprayed from the nozzle 1 to the surface of the circular workpiece 3 at high speed after being accelerated by the water flow. The specific process parameters are as follows: the water pressure is 300MPa, the diameter of the nozzle 1 is 0.33mm, the distance between the nozzle 1 and the surface of the circular workpiece 3 is 10mm, the injection method is a straight line injection, and the mixed abrasive is glass pellets (SiO 2 ) and steel ba...

Embodiment 2

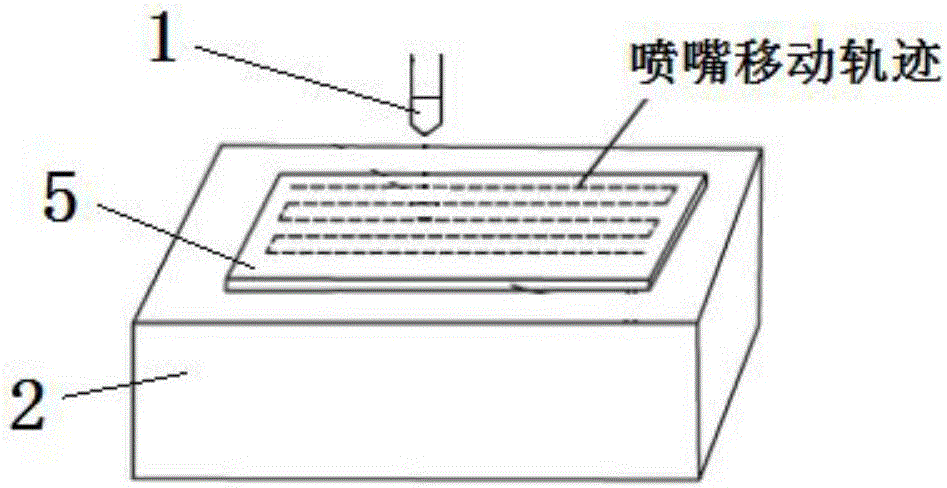

[0018] The workpiece to be sprayed in this embodiment is a flat low-carbon steel part that has been carburized. see figure 2 Firstly, the flat workpiece 5 is fixed on the water tank 2 through the fixture, and then the surface of the flat workpiece 5 is strengthened by means of ultra-high pressure numerical control water jet, that is, the mixed abrasive relies on its own weight and the negative pressure generated by the high-speed water flow to make the mixed abrasive enter the mixing chamber. The tube is mixed with water, and the mixed abrasive is sprayed together with the water flow from the nozzle 1 to the surface of the flat workpiece 5 at high speed after being accelerated by the water flow. The specific process parameters are as follows: the water pressure is 250MPa, the diameter of the nozzle 1 is 0.33mm, the distance between the nozzle 1 and the surface of the flat workpiece 5 is 15mm, the injection method is a straight line injection, and the mixed abrasive is glass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com