Glass-furnace-smoke integrated-denitration-desulfurization-dedusting technological device and technology

A technology for desulfurization, dust removal, and process equipment, which is applied in the field of flue gas purification to achieve the effects of ensuring long-term continuous service life, small resistance, and reducing investment and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in conjunction with accompanying drawing and specific embodiment:

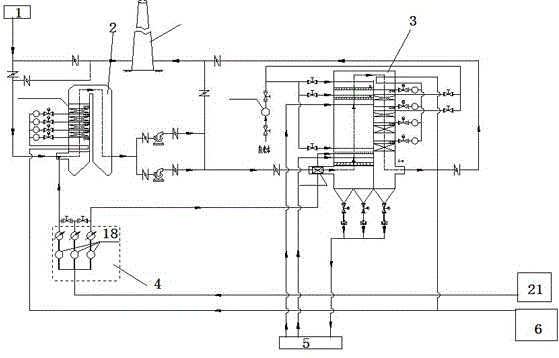

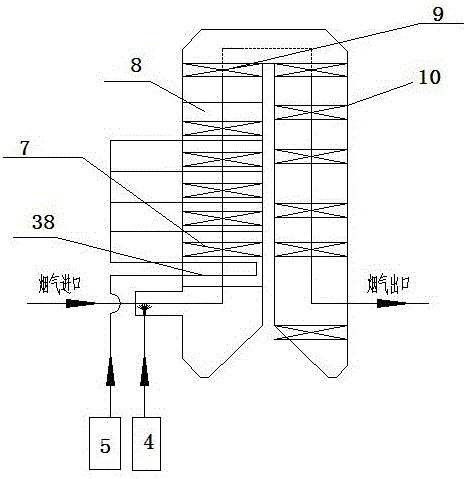

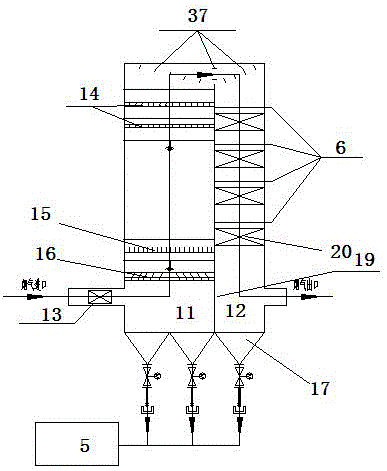

[0035] Such as figure 1 As shown, a glass kiln flue gas synchronous denitrification, desulfurization and dust removal process equipment, said process equipment includes a waste heat boiler 2, a low-temperature denitrification, desulfurization and dust removal reaction tower 3, an ammonia water system 4, a water treatment system 5, and a compressed air system 6; combine figure 2 , the waste heat boiler 2 is an inverted U shape, and the furnace is provided with a primary heat exchanger 7, a medium temperature denitrification reactor 8, a secondary heat exchanger 9 and a secondary heat The multi-stage heat exchanger 10 behind the device; the flue gas inlet of the waste heat boiler 2 is arranged at the lower part of the waste heat boiler, and communicates with the flue gas outlet of the glass kiln 1; the ammonia water system 4 passes through the ammonia water pump 18, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com