Pyraclostrobin synergistic water suspension agent and preparation method thereof

A technology of pyraclostrobin and water suspending agent, applied in the field of pyraclostrobin synergistic water suspending agent and its preparation, can solve the problem of water suspending agent that is not easy to high content, affects the use effect, and the particle size is easy to increase, etc. problems, to improve the prevention and control effect, reduce manufacturing costs and transportation costs, and achieve the effects of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

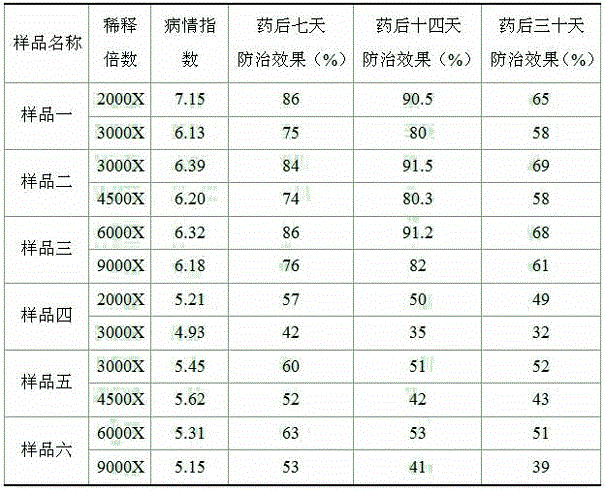

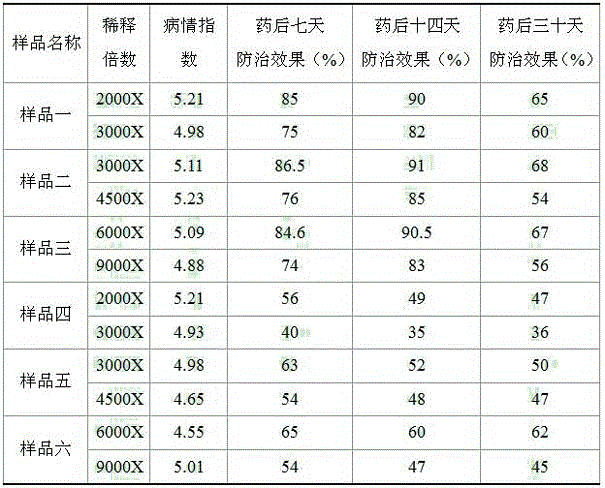

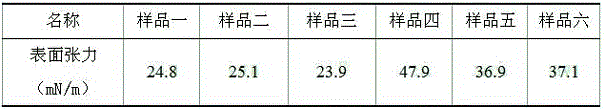

Examples

Embodiment 1

[0019] Add 648 grams of water and 20 grams of guar gum hydroxypropyltrimethylammonium chloride into a reactor with a heating jacket, stir evenly, then add 50 grams of dispersing wetting agent ammonium xylenesulfonate, thickener xanthan 2 grams of glue, 8 grams of magnesium aluminum silicate, 50 grams of antifreeze urea, 1 gram of antifoaming agent polyether, 1 gram of preservative sodium benzoate, synergist glycerol tristearate, 20 grams and pyraclostrobin Mix 200 grams of the original drug evenly, and perform high-speed shearing at 12,000 rpm for 20 minutes; then perform secondary sand milling to a particle size of ≤ 5 μm to obtain a 20% pyraclostrobin aqueous suspension concentrate, which is recorded as sample 1.

Embodiment 2

[0021] Add 532 grams of water and 30 grams of guar gum hydroxypropyltrimethylammonium chloride in a reactor with a heating jacket, stir evenly, then add 60 grams of dispersing wetting agent ammonium xylenesulfonate, thickener yellow 1 gram of raw gum, 5 grams of magnesium aluminum silicate, 40 grams of antifreeze urea, 1 gram of defoaming agent n-octanol, 1 gram of preservative sodium benzoate, 30 grams of synergist glycerol tristearate and pyrazole ether bacteria Mix 300 grams of the ester drug evenly, and perform high-speed shearing at 12,000 rpm for 30 minutes; then perform secondary sand milling until the particle size is ≤ 5 μm to obtain a 30% synergistic pyraclostrobin aqueous suspension, which is recorded as sample 2 .

Embodiment 3

[0023] Add 197 grams of water and 50 grams of guar gum hydroxypropyltrimethylammonium chloride into a reactor with a heating jacket, stir evenly, then add 60 grams of dispersing wetting agent ammonium xylenesulfonate, thickener silicon 0.5 g of magnesium aluminum phosphate, 0.5 g of xanthan gum, 30 g of antifreeze urea, 1 g of antifoaming agent simethicone, 1 g of preservative sodium benzoate, 60 g of synergist glycerol tristearate and pyrazole ether Mix 600 grams of strytostrobin original drug evenly, and perform high-speed shearing at 12,000 rpm for 50 minutes; then perform secondary sand milling until the particle size is ≤5 μm, and 60% pyraclostrobin aqueous suspension can be obtained, which is recorded as a sample three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com