Preparation method of single-component photo-initiation self-healing silicon dioxide-based microcapsule

A silicon dioxide, light-induced technology, applied in the directions of silicon dioxide, microcapsule preparation, silicon oxide, etc., can solve the problems of atomic oxygen damage, failure, etc., to improve strength, good weather resistance and temperature resistance, and flexible formula Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Mix 1g of bisphenol A type epoxy resin E-51, 1g of alicyclic epoxy resin A1815, 0.4g of cationic photoinitiator PI6992 and 1g of tetraethyl orthosilicate as the oil phase, and mix it with 40mL of 2% non- The aqueous solution of ionic surfactant F-127 was mixed and stirred by 8000rpm high-speed homogenizer for 15min to form an O / W emulsion; transfer the O / W emulsion to a round bottom flask and add 400μL pre-prepared 2mol / L Dilute hydrochloric acid solution, heat up to 50°C, start the reaction at 300rpm, after 3 hours, add 1mL tetraethyl orthosilicate, and add 400μL 2mol / L dilute hydrochloric acid solution every 4 hours, add a total of 3 times, continue the reaction for 12h, After the reaction is complete, wash with deionized water several times until the supernatant is colorless and transparent, and place it in an oven to dry.

Embodiment 2

[0017] Mix 1g of bisphenol A type epoxy resin E-51, 1g of alicyclic epoxy resin A1815, 0.6g of cationic photoinitiator PI6992 and 1g of tetraethyl orthosilicate as the oil phase, and mix with 40mL of 2% non- The aqueous solution of ionic surfactant F-127 was mixed and stirred by 8000rpm high-speed homogenizer for 15min to form an O / W emulsion; transfer the O / W emulsion to a round bottom flask and add 500μL pre-prepared 2mol / L Dilute hydrochloric acid solution, heat up to 50°C, start reaction at 300rpm, after 3 hours, add 1.5mL tetraethyl orthosilicate, and add 500μL dilute hydrochloric acid solution with a concentration of 2mol / L every 4 hours, add 3 times in total, Continue to react for 12 hours. After the reaction is complete, wash with deionized water several times until the supernatant is colorless and transparent, and place it in an oven to dry.

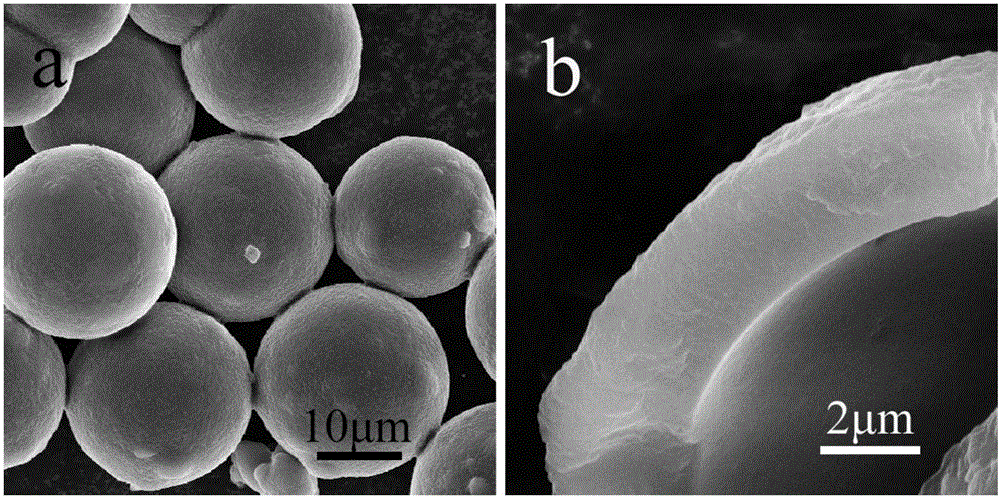

[0018] Such as figure 1 As shown, it can be seen that the surface of the prepared microcapsules is relatively dense, the part...

Embodiment 3

[0021] Mix 1g of bisphenol A type epoxy resin E-51, 1g of alicyclic epoxy resin A1815, 0.8g of cationic photoinitiator PI6992 and 1g of tetraethyl orthosilicate as the oil phase, and mix them with 40mL of 2% non- The aqueous solution of ionic surfactant F-127 was mixed and stirred by a high-speed homogenizer at 8000 rpm for 15 minutes to form an O / W emulsion. Transfer the O / W emulsion to a round bottom flask, add 600 μL of pre-prepared 2mol / L dilute hydrochloric acid solution dropwise, raise the temperature to 50°C, and start the reaction at a speed of 300rpm. After 3 hours, add 1.5mL tetraethyl orthosilicate At the same time, add 600 μL of dilute hydrochloric acid solution with a concentration of 2mol / L every 4 hours, add a total of 3 times, continue to react for 12 hours, after the reaction is complete, wash with deionized water for several times until the supernatant is colorless and transparent, and place it in an oven to dry .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com