Method for sectioned construction of open-off cut of sharp inclined coal seam

A technology of cutting holes and steep inclinations, which is applied in the construction field of cutting holes in fully mechanized mining faces. It can solve the problems of low drilling positioning accuracy, partial drilling, and large safety threats, so as to prevent flying gangue from hurting people and people from falling , reduce security threats, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

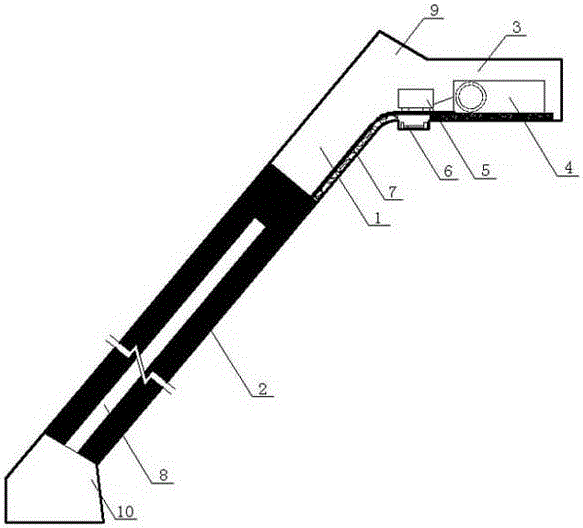

[0016] see figure 1 , a method for segmental construction of steeply inclined coal seam cutting eyelets, the method comprises the following steps.

[0017] Step 1. Excavation of the small section of the upper section of the cut hole (1): first construct an installation chamber (3) in the appropriate position of the wind tunnel (9) and install the column return machine (4), and install the upper section of the cut hole (1) into the wind tunnel (9) The position is undercovered and the scraper conveyor (6) is installed. The upper section of the cut hole (1) is constructed from top to bottom by the drill and blast method, and the four-sided support technology is used to excavate a certain distance down before laying Track (7), the moraine head coal gangue is manually loaded into the specia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com