Filter material finishing liquid for improving filtering precision, and preparation method and application thereof

A technology of filtration accuracy and finishing liquid, which is applied in the processing of textile materials, chemical instruments and methods, liquid/gas/steam textile material processing, etc. It can solve the problems affecting the filtering effect, so as to improve the service life and interception ability , Simple formula and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The production technology of the filter material of the present embodiment comprises the following steps:

[0027] (1) After combing the filter material fiber, lay the net up and down on the base cloth;

[0028] (2) Reinforce filter fiber and base cloth by acupuncture;

[0029] (3) then carry out calendering and singeing and make filter material for subsequent use;

[0030] (4) above-mentioned filter material is immersed in finishing liquid, carries out impregnation finishing;

[0031] (5) After drying and finalizing, the finished product is rolled up. The drying temperature is from low to high and then to low, and the temperature range is between 180 ° C and the softening point of the fiber. Drying and shaping include multiple temperature zones, and the temperature of the multiple temperature zones goes from low to high, and then from high to low.

[0032] The multiple temperature ranges are 180-200°C, 200-220°C, 220-240°C, 240-260°C, 260-220°C, and 220-180°C in seq...

Embodiment 2

[0037] In this embodiment, the finishing solution used includes the following components by weight: 5% PTFE emulsion, 0.5% JFC penetrant, 0.5% Tween, 1% silicone oil, 1% silicone oil emulsion, and the balance is water.

[0038] Other implementations are the same as in Example 1.

Embodiment 3

[0040] In this embodiment, the finishing solution used includes the following components by weight: 6% PTFE emulsion, 1% JFC penetrant, 0.8% Tween, 2% silicone oil, 2% silicone oil emulsion, and the balance is water.

[0041] Other implementations are the same as in Example 1.

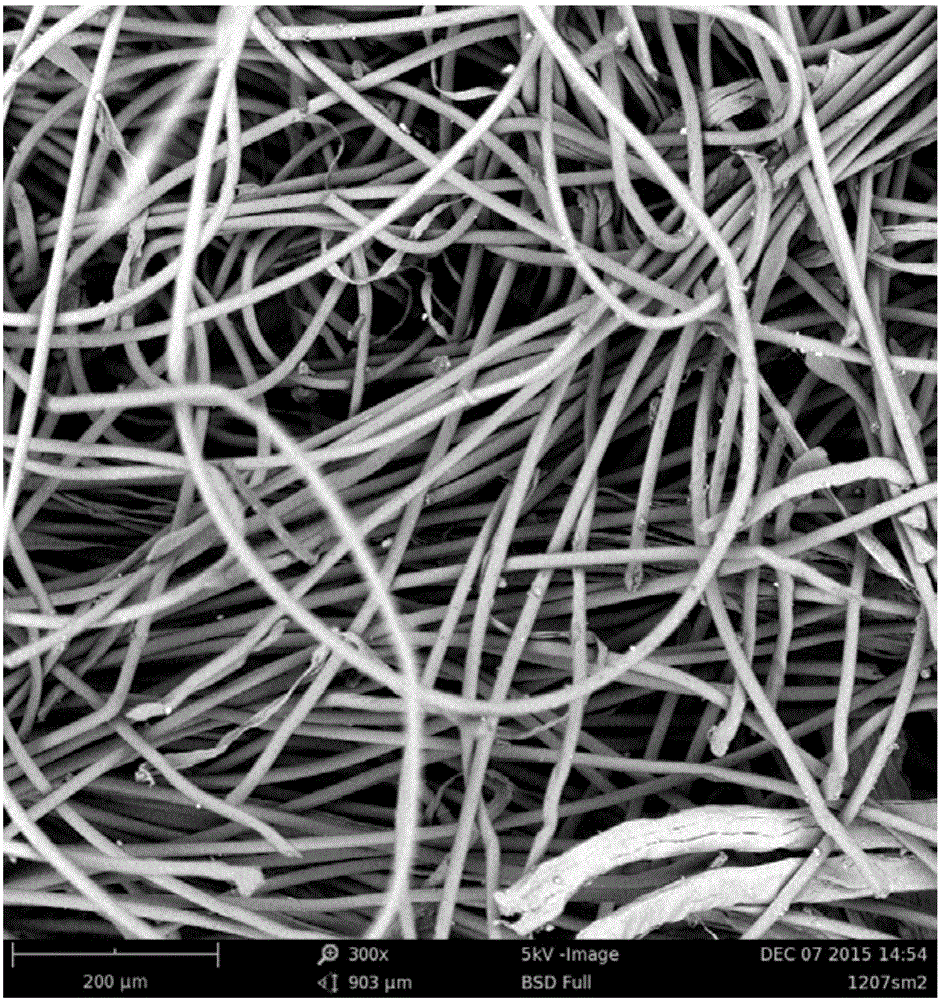

[0042] Such as figure 1 Shown is a photograph under a scanning electron microscope of a filter material that does not use a finishing solution. It can be seen from the figure that the fibers of the filter material are intertwined with each other and have clear gaps.

[0043] Such as figure 2 and image 3 As shown, after impregnated with the finishing liquid, there is a sheet-like film between the fibers of the filter material, and the gaps between the fibers are filled by the film, and the gaps become smaller. Obviously, after impregnating with the finishing liquid, the gaps between the fibers are significantly reduced, which will Has a better filtering effect. Before use, the filter material is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com