Modified fuel slurry of oily solid waste and preparation method thereof

A solid waste and fuel slurry technology, applied in the direction of solid waste removal, etc., can solve the problems of high energy consumption, non-compliance with environmental discharge standards, etc., and achieve low energy consumption, elimination of environmental or safety hazards, and high operational safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

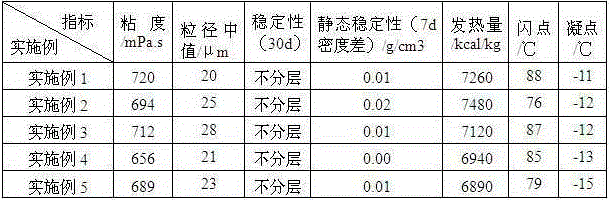

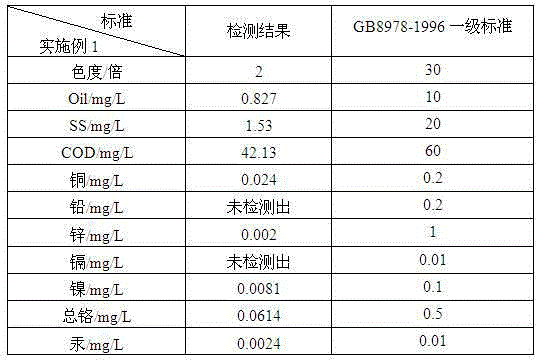

Examples

Embodiment 1

[0031] Example 1: (1) Weigh 20% conditioner and 10% tap water according to the weight ratio and add them to the reactor with stirring, and stir evenly under normal temperature and pressure, and the stirring time is 0.5h~1h to obtain the conditioner agent aqueous solution;

[0032] (2) Weigh 70% of the oil-based drilling cuttings according to the weight ratio and add them to the aqueous solution of the conditioning agent described in step (1), and stir evenly at room temperature and pressure in a closed manner. The stirring time is 0.5h~1h, and the light dark brown Oily solid waste modified fuel slurry.

Embodiment 2

[0033] Example 2: (1) Weigh 25% conditioner and 15% drilling wastewater according to the weight ratio and add them to the reactor with stirring, and stir evenly under normal temperature and pressure, and the stirring time is 0.5h~1h, and the adjusted Aqueous solution of quality agent;

[0034] (2) Weigh 60% of the oil-based drilling cuttings according to the weight ratio and add them to the aqueous solution of the conditioning agent described in step (1), and stir evenly at room temperature and pressure in a closed manner. The stirring time is 0.5h~1h to obtain light dark brown Oily solid waste modified fuel slurry.

Embodiment 3

[0035] Example 3: (1) Weigh 15% conditioner and 20% drilling wastewater according to the weight ratio and add them to the reactor with stirring, and stir evenly at normal temperature and pressure, and the stirring time is 0.5h~1h, and the adjusted Aqueous solution of quality agent;

[0036] (2) Weigh 65% of the oil-based drilling cuttings according to the weight ratio and add them to the aqueous solution of the conditioning agent described in step (1), and stir evenly at room temperature and pressure in a closed manner. The stirring time is 0.5h~1h to obtain light dark brown Oily solid waste modified fuel slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com