Sheath material for long-life radiation-resistant cable and preparation method thereof

A sheath material and radiation resistance technology, applied in the field of power cables, can solve the problem that the performance of the cable sheath material cannot meet the high requirements, and achieve excellent radiation resistance, strong acid and alkali resistance, and strong heat aging resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

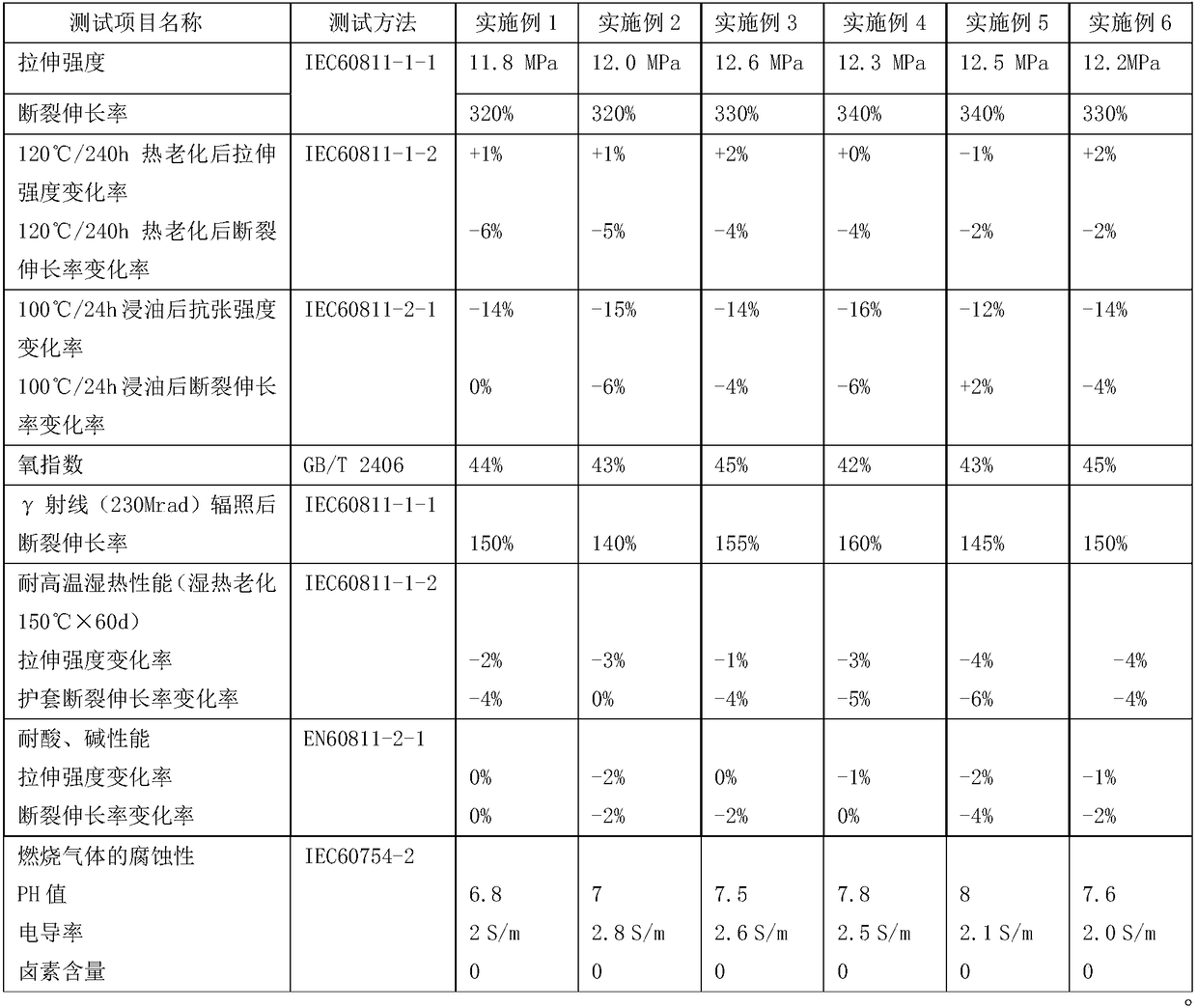

Examples

Embodiment 1

[0038] A sheath material for a long-life radiation-resistant cable, the raw material formula components and the weight ratio of each component are:

[0039] 80 parts of ethylene vinyl acetate copolymer 40X (Mitsui-DuPont);

[0040] Maleic anhydride grafted EVA (Shanghai Jiuju 265B) 20 parts;

[0041] 155 parts of flame retardant, specifically including: composite flame retardant (melamine with a mass ratio of 1:2:3, microencapsulated red phosphorus RP-85 (Shanghai Zhuo Yu Chemical Co., Ltd.) and silicate (Langfang Qiyuan Refractory Energy-saving materials Co., Ltd., compounding of silicate paint) 5 parts, 100 parts of aluminum hydroxide and 50 parts of magnesium hydroxide;

[0042] 3 parts of antioxidants, including: 1 part of 2,2,4-trimethyl-1,2-dihydroquinoline polymer (Sumitomo, Japan) and tetrakis (3-(3,5-di-tert-butyl- 2 parts of 4-hydroxyphenyl) propionate) pentaerythritol ester;

[0043] 3 parts of stabilizer, including: 1.5 parts of 2-hydroxy-4-n-octyloxybenzophenon...

Embodiment 2

[0056] A sheath material for a long-life radiation-resistant cable, the raw material formula components and the weight ratio of each component are:

[0057] Ethylene vinyl acetate copolymer 450 (Mitsui-DuPont) 85 parts;

[0058] Maleic anhydride grafted EVA (Shanghai Jiuju 265B): 15 parts

[0059]165 parts of flame retardant, specifically including: composite flame retardant (melamine with a mass ratio of 1:3:2, microencapsulated red phosphorus RP-85 (Shanghai Zhuoyu Chemical Co., Ltd.) and silicate (Langfang Qiyuan Refractory Co., Ltd. Energy-saving materials Co., Ltd., compounding of silicate paint) 5 parts, 80 parts of aluminum hydroxide and 80 parts of magnesium hydroxide;

[0060] 3.5 parts of antioxidants, specifically including: 1 part of 2,2,4-trimethyl-1,2-dihydroquinoline polymer (Sumitomo, Japan) and 4,4 dicumyl diphenylamine (chemtura ) 2.5 copies;

[0061] 3 parts of stabilizer, including: 1.5 parts of 2-hydroxy-4-n-octyloxybenzophenone and 1.5 parts of 2-(2-hy...

Embodiment 3

[0070] A sheath material for a long-life radiation-resistant cable, the raw material formula components and the weight ratio of each component are:

[0071] 90 parts of ethylene vinyl acetate copolymer 450 (Mitsui-DuPont);

[0072] Maleic anhydride grafted EVA (Shanghai Jiuju 265B): 10 parts

[0073] 105 parts of flame retardant, specifically including: composite flame retardant (melamine with a mass ratio of 1:2:3, microencapsulated red phosphorus RP-85 (Shanghai Zhuoyu Chemical Co., Ltd.) and silicate (Langfang Qiyuan Refractory Energy-saving materials Co., Ltd., silicate coating) compound) 5 parts, aluminum hydroxide 40 parts and magnesium hydroxide: 60 parts;

[0074] 3 parts of antioxidants, specifically including: 1.5 parts of tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester and 4,4 dicumyl diphenylamine (Komol sub) 1.5 copies;

[0075] 3 parts of stabilizer, including: 1.5 parts of 2-hydroxy-4 n-octyloxybenzophenone and 2-(2-hydroxy-3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com