Cable insulant for third-generation nuclear power station and preparation method thereof

A cable insulation and nuclear power plant technology, applied in the field of power cables, can solve problems such as unachievable performance and decreased insulation resistance, and achieve the effects of improving original mechanical properties, reducing chain breakage, and excellent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

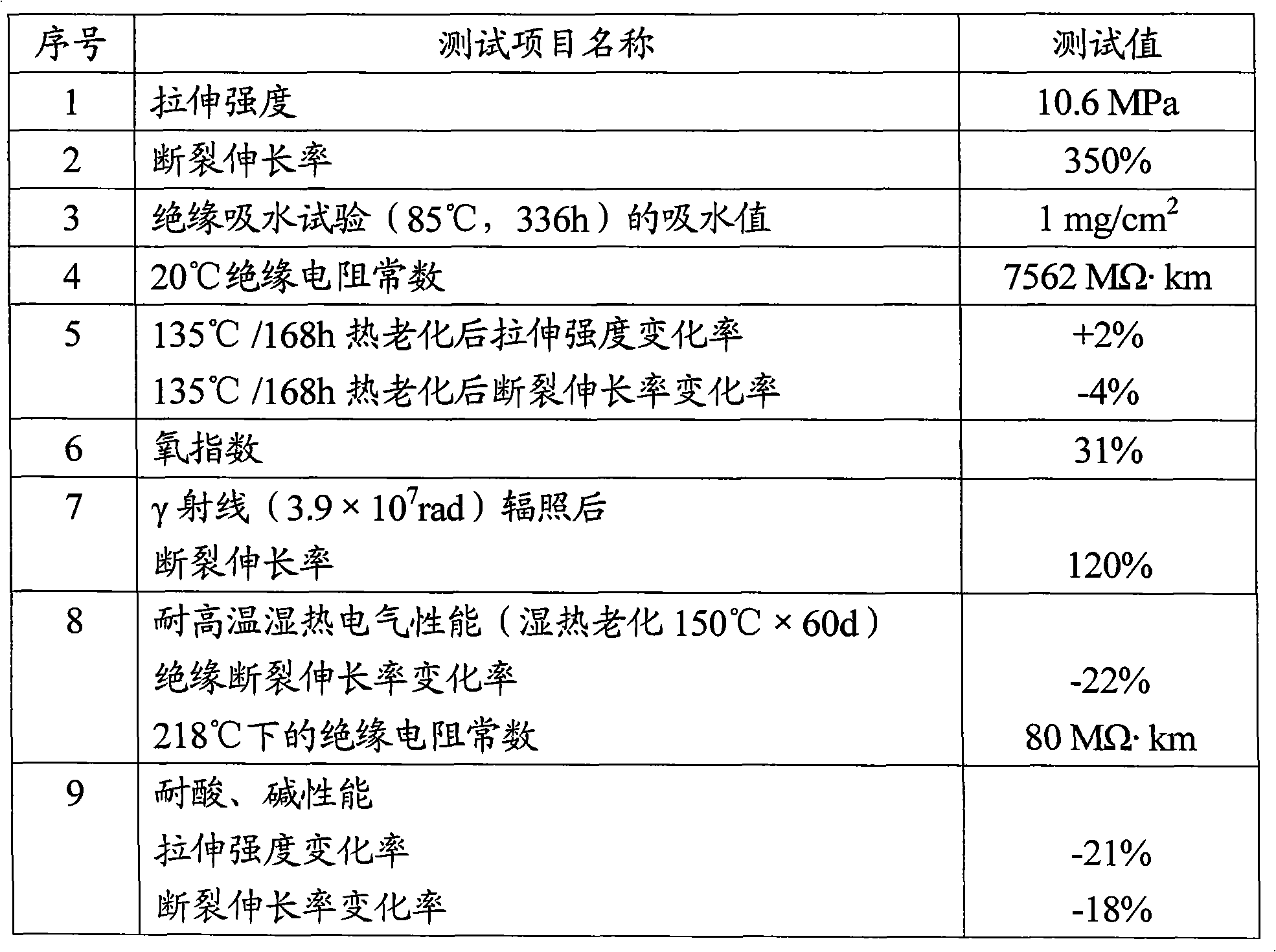

Examples

Embodiment 1

[0031] The main process equipment required for the preparation of the product of the present invention are: internal mixer, rubber filter machine, three-roll page rolling machine, rubber extruder, etc.

[0032] A cable insulation material for third-generation nuclear power plants, its raw material formula components and the weight ratio of each component are:

[0033] The ethylene-propylene rubber copolymer is binary ethylene-propylene rubber-maleic anhydride copolymer: 100 parts;

[0034] Active agent is zinc oxide: 6.5 parts;

[0035] The flame retardant is nano-montmorillonite, aluminum hydroxide and magnesium hydroxide: a total of 115 parts;

[0036] Nano-montmorillonite: 5 parts;

[0037] Aluminum hydroxide: 100 parts;

[0038] Magnesium hydroxide: 10 parts;

[0039] Antioxidants are methylthiolbenzimidazole and zincated diphenylamine: 3.5 parts; among them, methylthiolbenzimidazole: 1.5 parts;

[0040] Zinc-based diphenylamine: 2 parts;

[0041] Stabilizers are met...

Embodiment 2

[0051]The main process equipment required for the preparation of the product of the present invention are: internal mixer, rubber filter machine, three-roll page rolling machine, rubber extruder, etc.

[0052] A cable insulation material for third-generation nuclear power plants, its raw material formula components and the weight ratio of each component are:

[0053] The ethylene-propylene rubber copolymer is binary ethylene-propylene rubber-maleic anhydride copolymer: 100 parts;

[0054] Active agent is zinc oxide: 8 parts;

[0055] The flame retardant is nano-montmorillonite, aluminum hydroxide and magnesium hydroxide: a total of 140 parts;

[0056] Nano-montmorillonite: 5 parts;

[0057] Aluminum hydroxide: 90 parts;

[0058] Magnesium hydroxide: 45 parts;

[0059] Antioxidants are two kinds of methyl mercaptan benzimidazole and zinc-based diphenylamine: 3 parts;

[0060] Methylthiolbenzimidazole: 1.5 parts;

[0061] Zinc-based diphenylamine: 1.5 parts;

[0062] Stab...

Embodiment 3

[0073] The main process equipment needed for the preparation of the product of the present invention are: internal mixer, rubber filter machine, three-roll page rolling machine, rubber extrusion machine, etc.

[0074] A cable insulation material for third-generation nuclear power plants, its raw material formula components and the weight ratio of each component are:

[0075] The ethylene-propylene rubber copolymer is binary ethylene-propylene rubber-maleic anhydride copolymer: 100 parts;

[0076] Active agent is zinc oxide: 6.5 parts;

[0077] Flame retardants are three kinds of nano-montmorillonite, aluminum hydroxide and magnesium hydroxide: a total of 90 parts;

[0078] Nano-montmorillonite: 5 parts;

[0079] Aluminum hydroxide: 80 parts;

[0080] Magnesium hydroxide: 5 parts;

[0081] Antioxidants are two kinds of methyl mercaptan benzimidazole and zinc-based diphenylamine: 4 parts;

[0082] Methylthiolbenzimidazole: 2 parts;

[0083] Zinc-based diphenylamine: 2 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com