A packaging structure and packaging method for improving the mechanical strength of frit packaging

An encapsulation method and encapsulation layer technology, which are applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of fragile fracture, inability to effectively release glass extrusion stress and impact stress, etc., to improve adhesion force, reducing laser power, increasing the effect of weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

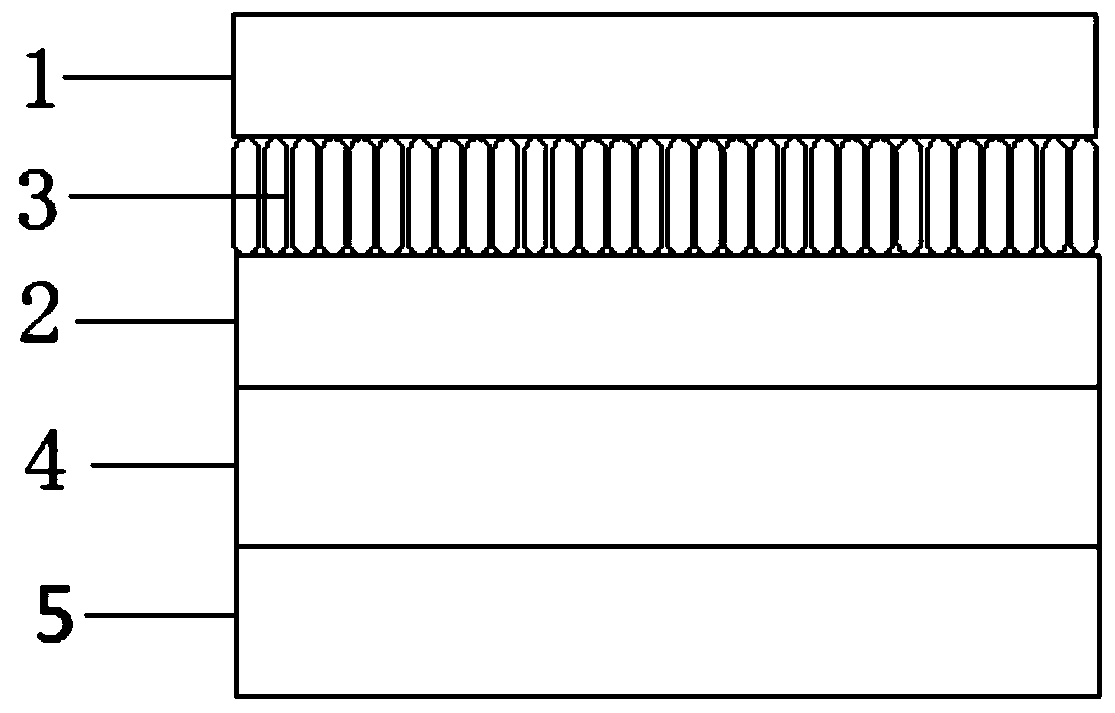

[0033] Such as figure 1 Shown, make metal film layer 4 on substrate 5, prepare inorganic quantum dot nano film layer 3 on cover glass 1, then prepare Frit encapsulation layer 2 on inorganic quantum dot nano film layer 3, metal on substrate 5 The film layer 4 is docked with the Frit encapsulation layer 2 on the cover glass 1 , and the cover glass 1 and the substrate 5 are welded and sealed by light irradiation. Preferably, the encapsulation area of the cover glass 1 and the substrate 5 is sealed by laser welding.

[0034] Wherein the thickness of the prepared inorganic quantum dot nano film layer 3 is 100nm~1000nm, the thickness of the prepared Frit encapsulation layer 2 is 4~6 μ m; the preferred inorganic quantum dot nano film layer 3 thickness is 800nm, the preferred Frit encapsulation layer 2 The thickness is 5 μm.

[0035] The method for preparing the inorganic quantum dot nano film layer includes one of a vapor phase deposition method, a 3D printing method, an inkjet p...

Embodiment 2

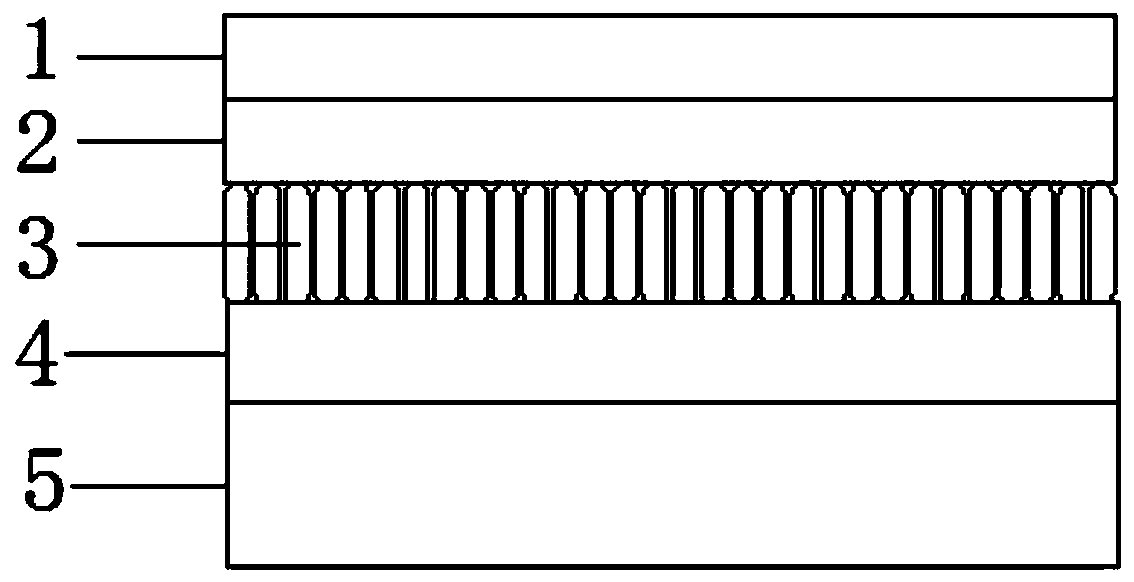

[0040] Such as figure 2Shown, different from embodiment 1 is: make metal film layer 4 on substrate 5, on cover glass 1 first prepare Frit encapsulation layer 2, then prepare inorganic quantum dot nano film layer 3 on Frit encapsulation layer 2, Then the metal film layer 4 on the substrate 5 is docked with the inorganic quantum dot nano film layer 3 on the cover glass 1, and the cover glass 1 and the substrate 5 are fused and sealed by light source irradiation, so that figure 2 structure shown. Preferably, the encapsulation area of the cover glass 1 and the substrate 5 is sealed by laser welding.

[0041] The thickness of the prepared inorganic quantum dot nano film layer 3 is 500nm~2000nm, the thickness of the prepared Frit encapsulation layer 2 is 4~6 μ m, the preferred inorganic quantum dot nano film layer 3 thickness is 1000nm, the preferred Frit encapsulation layer 2 The thickness is 5 μm.

[0042] In the above two embodiments, the inorganic quantum dot nano-film la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com