Durable anti-flaming anti-microbial mould-proof fabric, preparation method and application thereof

An antibacterial, mildew-proof, durable and flame-retardant technology, which is used in textiles, papermaking, fiber processing, etc., and can solve the requirements that the flame retardant grade 1 or B1 cannot be met, the flame retardant performance of flame retardant textiles is reduced, the after-burning time, the negative temperature Long burning time and other problems, to achieve the effect of intrinsic flame retardant and durable antibacterial and mildew resistance, ensure flame retardant performance, and beautify the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

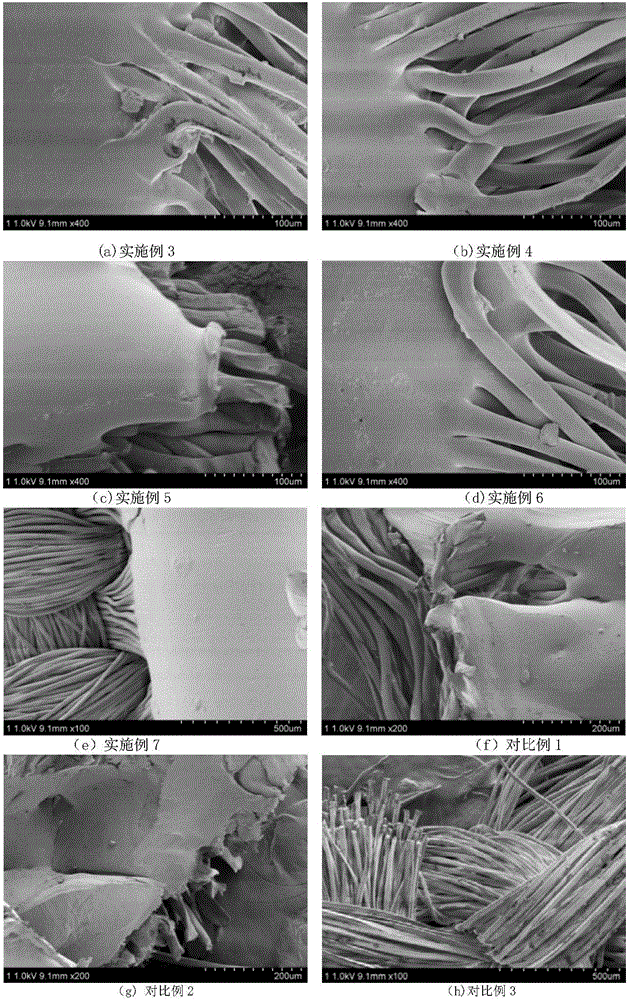

Examples

Embodiment 1

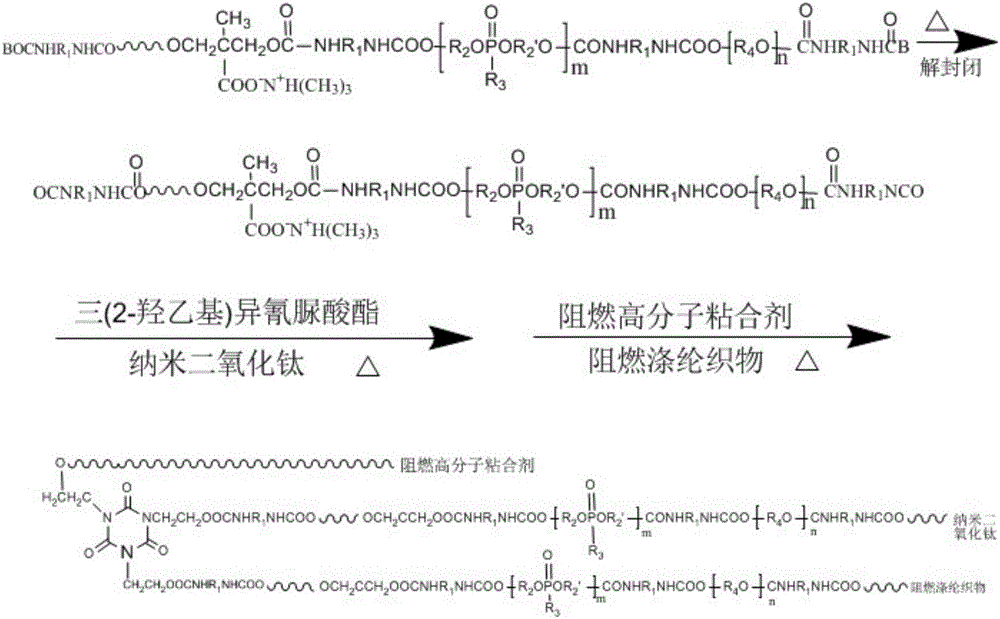

[0064] Weigh 40 grams of polyether polyol N210, 47.8 grams of phosphorus-containing polyester diol DM1304 (Beijing Dongfang Meilong Chemical Technology Co., Ltd. DM1304, molecular weight 478, hydroxyl value 233mgKOH / g, phosphorus content (wt, 19.7%), Add it to the reaction container, dehydrate and dry under reduced pressure for 1.5 hours at 110°C and a negative pressure with a vacuum gauge reading of -0.1MPa;

[0065] Weigh 36.5 grams of toluene diisocyanate, slowly drop it into the reaction vessel, and react at 75°C for 1.0 hour;

[0066] Cool down to below 60°C, add 6.7 grams of dimethylolpropionic acid to the reaction vessel, and react at 80°C for 1.5 hours;

[0067] Cool down to below 60°C, add 3.49 grams of methyl ethyl ketone oxime to the reaction vessel, add 10 grams of butanone to reduce the viscosity of the system, 0.5 hours;

[0068] Cool down to below 50°C, add 5.05 grams of triethylamine and 280 grams of water, control the degree of neutralization at 100%, emulsif...

Embodiment 2

[0070] Weigh 40 grams of polyether polyol N210, 48.4 grams of phosphorus-containing polyester diol PZ-1201 (Shandong Brothers Technology Co., Ltd., hydroxyl value 231.7mg KOH / g, phosphorus content (wt, 13.6%), add reaction In the container, dehydrate and dry under reduced pressure for 2 hours at 105°C and a negative pressure with a vacuum gauge reading of -0.1MPa;

[0071] Weigh 50.6 g of isophorone diisocyanate, slowly drop it into the reaction vessel, and react at 75°C for 1.0 hour;

[0072] Cool down to below 60°C, add 6.7 grams of dimethylolpropionic acid to the reaction vessel, and react at 80°C for 1.5 hours;

[0073] Cool down to below 60°C, add 5.23 grams of methyl ethyl ketone oxime to the reaction vessel, add 7 grams of butanone to reduce the viscosity of the system, 0.5 hours;

[0074] Cool down to below 50°C, add 5.05 grams of triethylamine and 312 grams of water, control the degree of neutralization at 100%, emulsify under high-speed stirring (10000RPM), and then...

Embodiment 3

[0076] (1) Weigh various components in a dispersion container, stir and disperse evenly: 2-thiocyanate methylthiobenzothiazole antibacterial agent is 1.2 grams, 1,2-benzisothiazolin-3-ketone ( BIT) antifungal agent is 2.0 grams, three (2-hydroxyethyl) isocyanurate (flame retardant synergist) is 0.3 grams, maleic acid dioctyl sodium sulfonate (penetrating agent) is 0.08 grams, dispersed in 50 grams of water for 15 minutes;

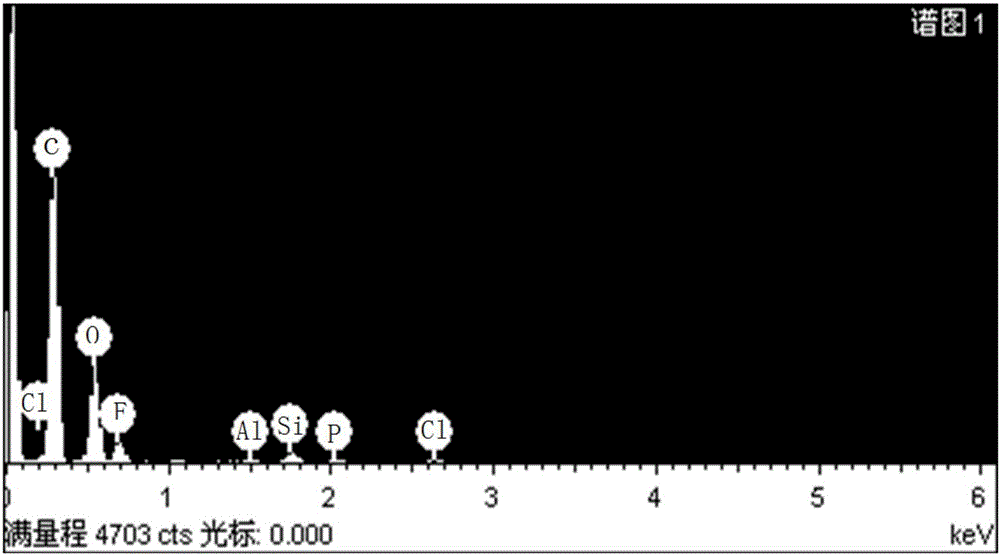

[0077] (2) For raw materials that themselves exist as emulsions or dispersions, the weights of various substances are weighed according to the concentration conversion of the actual substances, wherein the nanometer titanium dioxide solution is 1% concentration (Hangzhou Yunjie Biotechnology Co., Ltd.), then weighed It is 1.6 grams of solution, and the phosphorus-containing flame-retardant polyurethane emulsion (TF-686 of Zhejiang Chuanhua Co., Ltd.) is 40% concentration, then it is weighed as 3.0 grams, and the phosphorus-containing end-capped polyurethane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com