Heat/electric responding gel color changing glass material

A color-changing glass and responsive technology, which is applied in the field of thermal/electrically responsive gel color-changing glass materials, can solve the problems of easy volatilization, affecting operation stability and life, and easy leakage of water-soluble color-changing materials, so as to increase responsiveness, Effect of improving temperature controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] , , , , , , and One or a mixture of several components, Z in the formula 1 ,Z 2 ,Z 3 ,Z 4 ,Z 5 ,Z 6 ,Z 7 and Z 8 Each independently is an alkyl group with 1 to 12 carbon atoms, Y – for Cl – 、Br – , I – , NO 3 – , SO 4 2– 、PO 4 3– , OH – or TFSI – (bistrifluoromethanesulfonylimide ion). Its preparation method includes the following steps: (a) combining 4,4'-bipyridine with allyl bromide, methallyl bromide, acryloyl chloride, methacryloyl chloride, vinylbenzyl chloride, methylvinylbenzyl Vinyl compounds such as chlorine, p-vinylbenzoyl chloride or p-vinylmethylbenzoyl chloride are placed in an acetonitrile solution and reacted at 40-65°C for 5-10 hours, and the acetonitrile is removed by standing and layering (4, The molar ratio of 4'-bipyridine to vinyl compounds is 1:2~1:3); (b) The product of step (a) can be washed several times with ether.

[0024] The molar ratio of the thermoresponsive monomer to the crosslinking agent is 100-50:1...

Embodiment 1

[0028] This embodiment provides a thermal / electrical responsive gel color-changing glass material, and its preparation method includes the following steps:

[0029] (a) Mix 0.25g N-isopropylacrylamide (2.2mmol), 0.002g 4,4'-diallylbipyridine (0.002mmol), 0.002g ammonium persulfate (APS) and 0.004g tetramethylethyl Diamine (TEMED), dissolved in a mixed solvent composed of 0.8mL 1-methyl-3-butylimidazolium bromide and 0.2mL water, oscillating and stirring to make a homogeneous transparent solution;

[0030] (b) Transfer the homogeneous transparent solution obtained in step (a) into a 3mL ampule bottle, bubble with nitrogen for 10 minutes, then place it at 20°C for 30 minutes to polymerize, and take the obtained polymer gel out of the ampule bottle ;

[0031] (c) Spread gel1-1 evenly between two pieces of ITO glass for encapsulation.

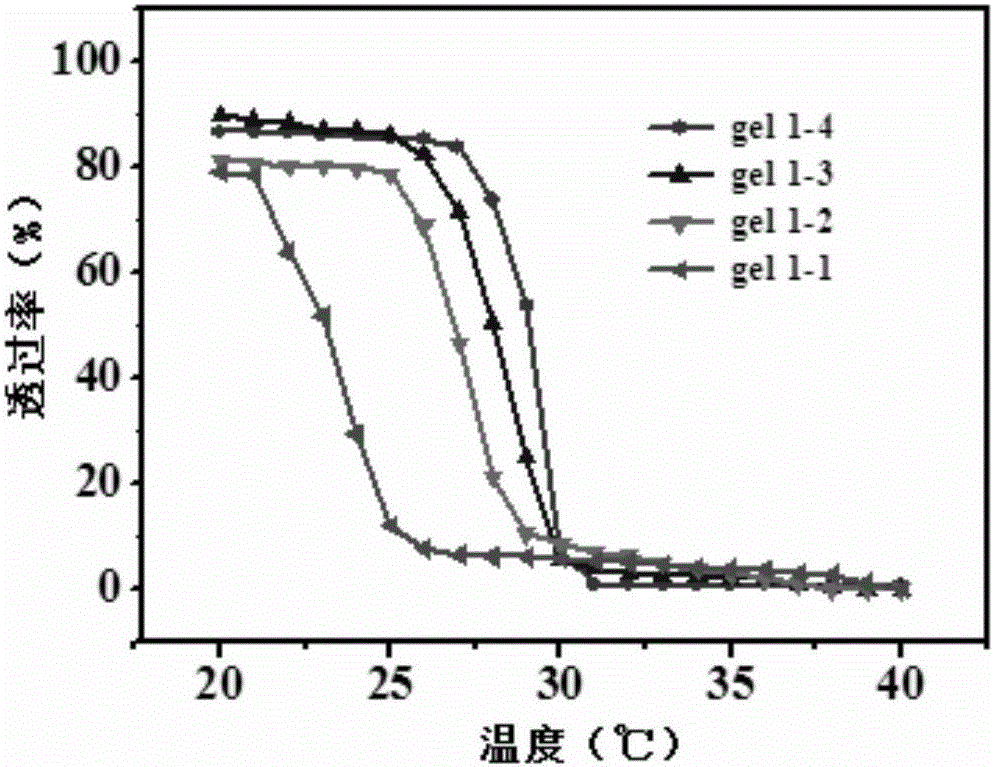

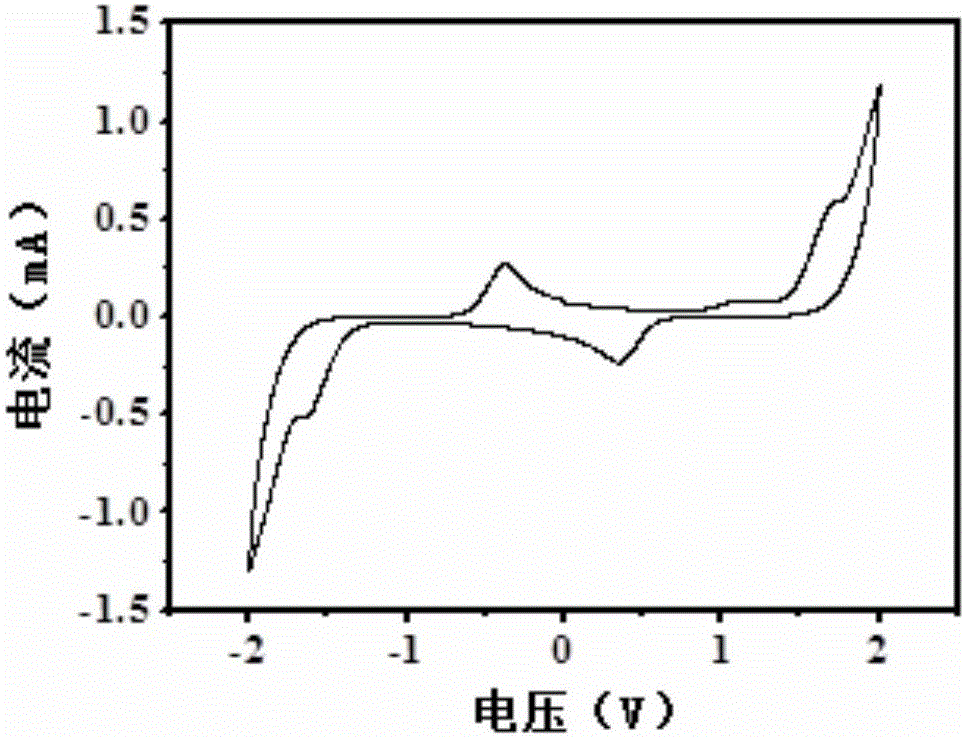

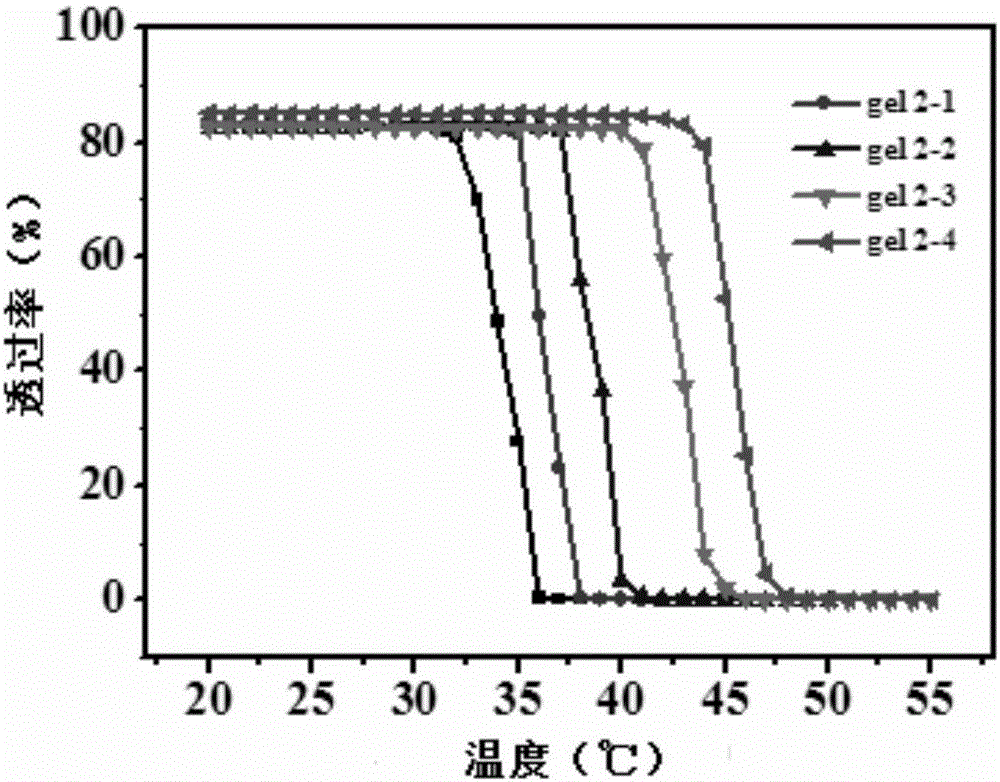

[0032] Through UV-vis (ultraviolet-visible absorption spectrum) test and CV (cyclic voltammetry) test, the color-changing glass material is milk...

Embodiment 2

[0034] This embodiment provides a thermal / electrical responsive gel color-changing glass material, and its preparation method includes the following steps:

[0035] (a) Mix 0.25g N-isopropylacrylamide (2.2mmol), 0.002g 4,4'-diallylbipyridine (0.002mmol), 0.002g ammonium persulfate (APS) and 0.004g tetramethylethyl Diamine (TEMED), dissolved in 0.6mL 1-methyl-3-butylimidazolium bromide salt and 0.4mL water mixed solvent, shake and stir to make a uniform transparent solution;

[0036] (b) Transfer the homogeneous transparent solution obtained in step (a) into a 3mL ampule bottle, and polymerize at 20°C for 30 minutes; take the obtained polymer out of the ampule bottle.

[0037] (c) Spread gel1-2 evenly between two pieces of ITO glass for encapsulation.

[0038] Through UV-vis (ultraviolet-visible absorption spectrum) test, CV (cyclic voltammetry) test, the color-changing glass material is higher than 25 o C is milky white, and it is transparent when it is lower than 25°C; it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com