V-W-Ti oxide catalyst, preparation method and application thereof

An oxide and catalyst technology, applied in the field of vanadium-tungsten-titanium oxide catalyst and its preparation, achieves the effects of wide operating temperature window, excellent low-temperature activity, and large variation in exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

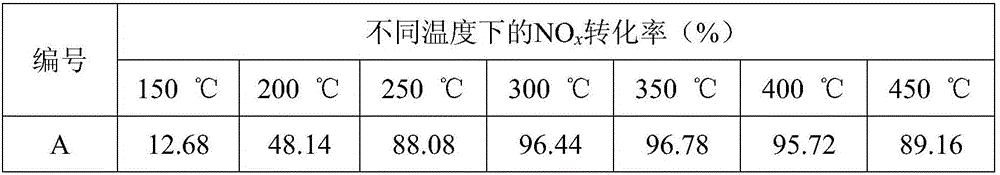

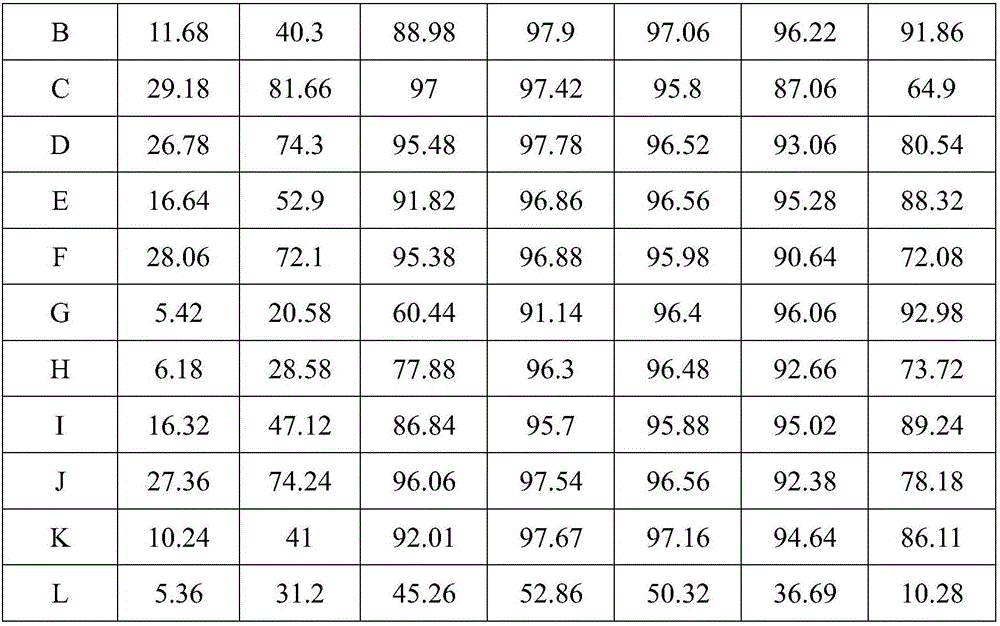

Examples

Embodiment 1

[0051] A vanadium tungsten titanium oxide catalyst, comprising the following components by mass percentage: 9% vanadium pentoxide, 12% tungsten trioxide and 79% titanium dioxide; the vanadium pentoxide, tungsten trioxide and titanium dioxide are uniformly mixed , and the crystal grain sizes of vanadium pentoxide, tungsten trioxide and titanium dioxide are independently 1-15 nm.

[0052] The preparation method of described vanadium tungsten titanium oxide catalyst comprises the steps:

[0053] Ammonium metavanadate is used as vanadium source, ammonium tungstate is used as tungsten source, titanium sulfate is used as titanium source, oxalic acid is used as co-solvent, and urea is used as slow-release precipitant.

[0054] Add ammonium metavanadate, ammonium tungstate and sulfuric acid to the solvent containing co-solvent (the mass of oxalic acid is the sum of the mass of ammonium metavanadate and ammonium tungstate) according to V:W:Ti molar ratio of 0.05:0.05:1 Titanium, made ...

Embodiment 2

[0056] A vanadium tungsten titanium oxide catalyst, comprising the following components by mass percentage: 8% vanadium pentoxide, 21% tungsten trioxide and 71% titanium dioxide; the vanadium pentoxide, tungsten trioxide and titanium dioxide are uniformly mixed , and the crystal grain sizes of vanadium pentoxide, tungsten trioxide and titanium dioxide are independently 1-15 nm.

[0057] The preparation method of described vanadium tungsten titanium oxide catalyst is:

[0058] Other conditions are the same as in Example 1, but the molar ratio of V:W:Ti is changed to 0.05:0.1:1, and the catalyst is marked as B.

Embodiment 3

[0060] A vanadium tungsten titanium oxide catalyst, comprising the following components by mass percentage: 17% of vanadium pentoxide, 11% of tungsten trioxide and 73% of titanium dioxide; the vanadium pentoxide, tungsten trioxide and titanium dioxide are uniformly mixed , and the crystal grain sizes of vanadium pentoxide, tungsten trioxide and titanium dioxide are independently 1-15 nm.

[0061] The preparation method of described vanadium tungsten titanium oxide catalyst is:

[0062] Other conditions were the same as in Example 1, and the molar ratio of V:W:Ti was changed to 0.1:0.05:1 to obtain the catalyst, marked as C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

| Crystal size | aaaaa | aaaaa |

| Crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com