Method for treating ethyl nitrite in sodium azide synthesis tail gas

A technology for the synthesis of ethyl nitrite and exhaust gas, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of waste of thermal energy resources, unfavorable economic benefits, and increase the cost of nitrite removal, and achieve protection Environmental protection, saving social heat energy resources, and reducing the effect of removal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

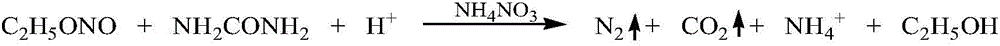

Method used

Image

Examples

Embodiment 1

[0032] Add 125g (2mol) mass fraction of 80% hydrazine hydrate aqueous solution and 81.6g (2.04mol) solid sodium hydroxide into 250mL ethanol, slowly feed ethyl nitrite at a rate of 30g / hour at 50°C, and the reaction time is 8 Hour. The tail gas produced is not condensed and directly passed into a two-stage absorption bottle with an absorption liquid temperature of 40°C. The two-stage absorption liquid is composed of 300g (5mol) urea + 588.7g (1.5mol) 31% hydrochloric acid + 5g ammonium nitrate + 606.3g water Prepare 20% urea acidic solution, and absorb the ethyl nitrite in the unabsorbed tail gas of the absorption device with 300mL-5°C absolute ethanol. After the reaction, the ethyl nitrite absorbed in the absolute ethanol was detected by gas chromatography, and the conversion rate of the ethyl nitrite in the tail gas in the absorption liquid was calculated to be 99.5%.

Embodiment 2

[0034] Add 125g (2mol) 80% hydrazine hydrate, 275g (2.2mol) 32% liquid caustic soda and 172.5g ethyl nitrite cooled to -5°C into the autoclave, react at 15-17°C for 10 hours, pass through the pressure regulating valve Limit the pressure in the kettle to ≤0.2Mpa, and the tail gas is not condensed and directly passed into the two-stage absorption bottle with the temperature of the absorption liquid at 40°C. The composition of the two-stage absorption liquid is 300g (5mol) urea + 588.7g (1.5mol) 31% hydrochloric acid + 5g nitric acid Ammonium + 606.3g water is configured as 20% urea acidic solution, and the ethyl nitrite in the unabsorbed tail gas of the absorption device is absorbed with 300mL-5°C absolute ethanol. After the reaction, the ethyl nitrite absorbed in the absolute ethanol was detected by gas chromatography, and the conversion rate of the ethyl nitrite in the tail gas was 99.4%.

Embodiment 3

[0036] Add 75g (1mol) of ethyl nitrite at -10°C to 150g of 80% ethanol aqueous solution, heat in a water bath at 35°C for 1 hour, and pass the generated ethyl nitrite gas directly into the two-stage absorbing liquid at 40°C without condensation. The absorption bottle, the two-stage absorption liquid is composed of 300g (5mol) urea + 588.7g (1.5mol) 31% hydrochloric acid + 5g ammonium nitrate + 606.3g water to configure a 20% urea acidic solution, the sub Absorb ethyl nitrate with 300mL-5°C absolute ethanol. After the reaction, the ethyl nitrite absorbed in the absolute ethanol was detected by gas chromatography, and the conversion rate of the ethyl nitrite in the tail gas was 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com