Preparation method of adsorbing agent simultaneously removing H2S and Hg in middle temperature coal gas

An adsorbent and medium-temperature technology, which is applied in chemical instruments and methods, selection of absorbent solid gas purification, and other chemical processes, can solve problems such as difficulties in the further application of gas, process safety issues, and restrictions on application and promotion. Efficient removal and harmless treatment, good desulfurization and mercury removal capabilities, and simplified process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A: Carrier pretreatment

[0034] First, a certain particle size of Al 2 o 3 The carrier was dried at 120°C for 3 hours, and placed in a desiccator for later use.

[0035] B: Preparation of precursor solution

[0036] Prepare 0.4g / ml Fe(NO 3 ) 3 9H 2 O solution.

[0037] C: Preparation of Adsorbent

[0038] Weigh 10g of pretreated γ-Al 2 o 3 Carrier in the crucible, measure 1.90ml Fe(NO 3 ) 3 9H 2 O was diluted with 11.10ml of distilled water and stirred evenly. Evenly added to the γ-Al 2 o 3 carrier crucible. Dry in the air for 10h, dry at 100°C for 12h, and roast at 500°C for 2h to obtain the adsorbent 3wt% Fe 2 o 3 / γ-Al 2 o 3 .

[0039] The prepared adsorbent 3wt% Fe 2 o 3 / γ-Al 2 o 3 Placed in a fixed bed reactor, reaction gas composition: 0.03vol% H 2 S, 60μg / m 3 Hg, 5vol%H 2 , 5vol% CO, 5vol% CO 2 , balance gas N 2 , the reaction volume space velocity is 5000h -1 , respectively at 100°C, 150°C, and 200°C for activity evaluation. When...

Embodiment 2

[0041] A: Carrier pretreatment

[0042] With embodiment 1.

[0043] B: Preparation of precursor solution

[0044] Prepare 0.1g / ml Pd(NO 3 ) 3 2H 2 O solution.

[0045] C: Preparation of Adsorbent

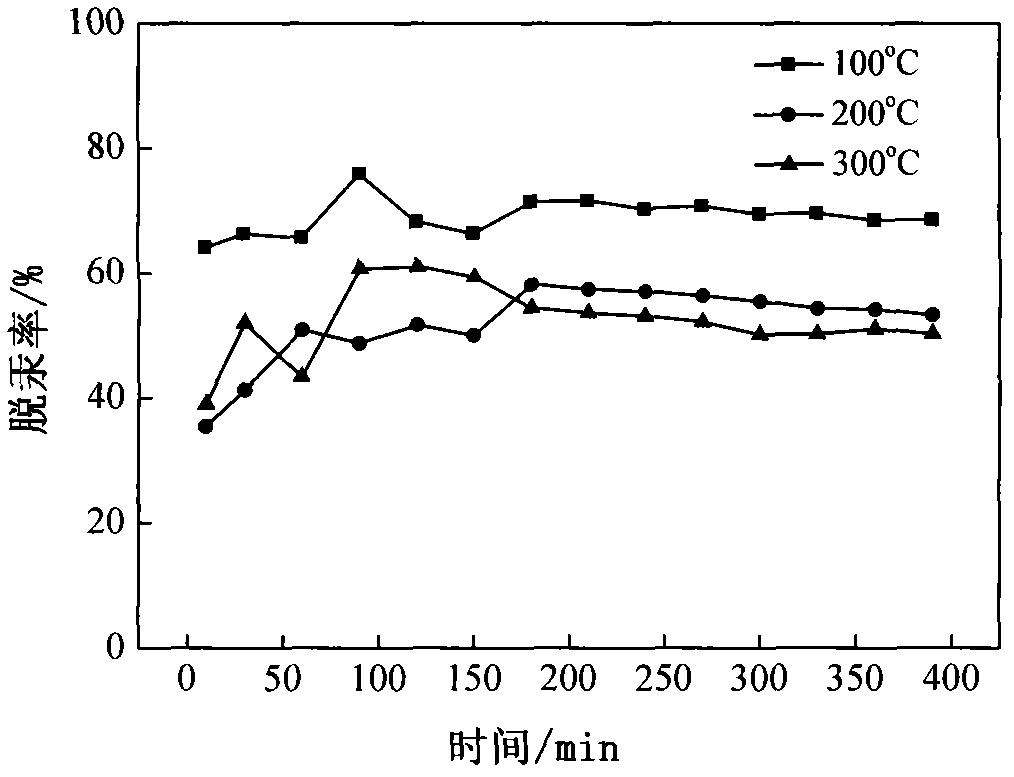

[0046] Weigh 10g of pretreated γ-Al 2 o 3 The carrier is placed in a crucible, and 2.00ml of Pd(NO 3 ) 2 2H 2 O was diluted with 11.00ml of distilled water and stirred. Evenly added to the γ-Al 2 o 3 carrier crucible. Air-dry for 10 hours, dry at 100°C for 12 hours, and bake at 500°C for 2 hours. Prepared Adsorbent 1wt%PdO / γ-Al 2 o 3 . The prepared adsorbent 1wt%PdO / γ-Al 2 o 3 Placed in a fixed bed reactor, reaction gas composition: 0.07vol% H 2 S, 80μg / m 3 Hg, 10vol%H 2 , 20vol% CO, 5vol% CO 2 , balance gas N 2 , the reaction volume space velocity is 5000h -1 , Activity evaluation was carried out at 100°C, 200°C, and 300°C, respectively. When the reaction temperature is 300°C and the reaction time is 400min, the mercury removal rate is 50%, the mercury cap...

Embodiment 3

[0048] A: Carrier pretreatment

[0049] Same as Example 1

[0050] B: Preparation of precursor solution

[0051] Prepare 0.4g / ml Fe(NO 3 ) 3 9H 2 O solution and 0.1 g / ml Pd(NO 3 ) 3 2H 2 O solution.

[0052] C: Preparation of Adsorbent

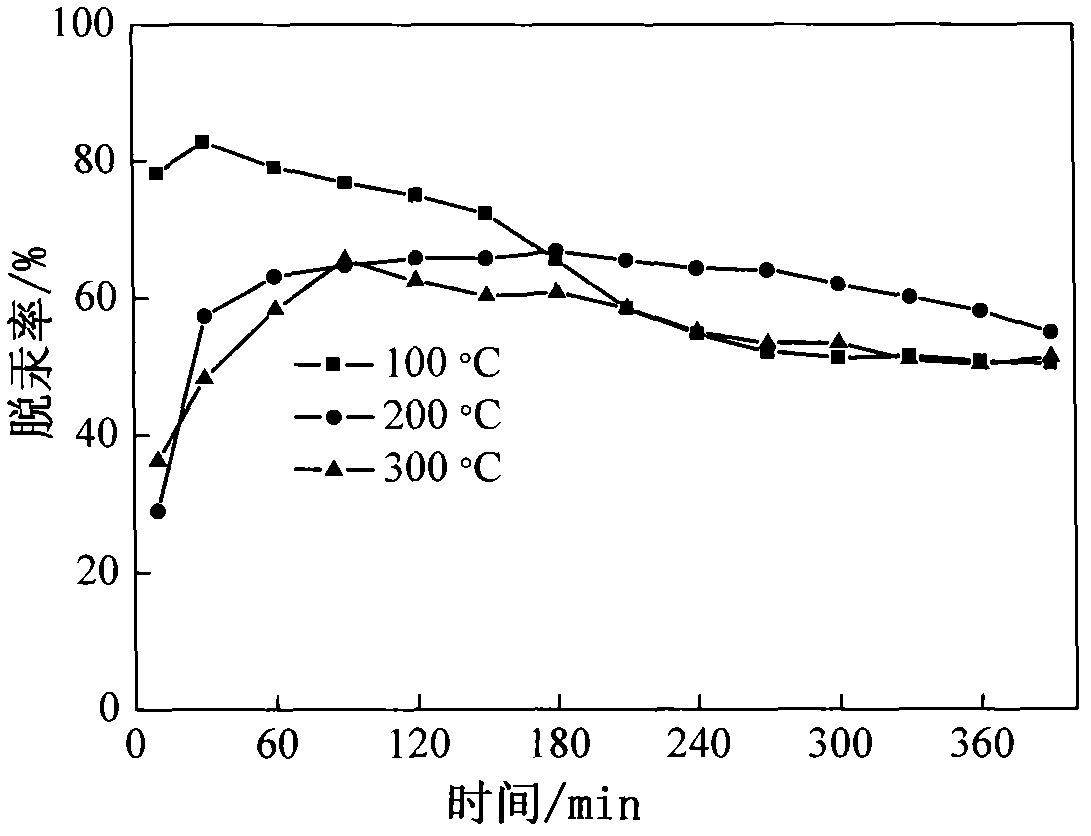

[0053] Weigh 10g of pretreated γ-Al 2 o 3 Carrier in the crucible, measure 1.90ml Fe(NO 3 ) 3 9H 2 O was diluted with 11.10ml of distilled water and stirred evenly. Evenly added to the γ-Al 2 o 3 carrier crucible. Air-dry for 10 hours, dry at 100°C for 12 hours, and bake at 500°C for 2 hours. Produced 3wt% Fe 2 o 3 / γ-Al 2 o 3 Adsorbent. Then measure 2.00ml Pd(NO 3 ) 2 2H 2 O was diluted with 11.00ml distilled water and stirred evenly. Uniformly added to the 3wt% Fe prepared above 2 o 3 / γ-Al2 o 3 In the adsorbent, air dry for 10 hours, dry at 100°C for 12 hours, and bake at 500°C for 2 hours. Prepared adsorbent 1wt%PdO3wt%Fe 2 o 3 / γ-Al 2 o 3 . The adsorbent prepared above is placed in a fixed-bed reactor, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com