Aspergillus flavus CS05 with high yield of aflatoxin B1 and application thereof

A technology of aflatoxin and Aspergillus flavus, which is applied to Aspergillus flavus CS05 and its application field, and can solve the problem of small toxin production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

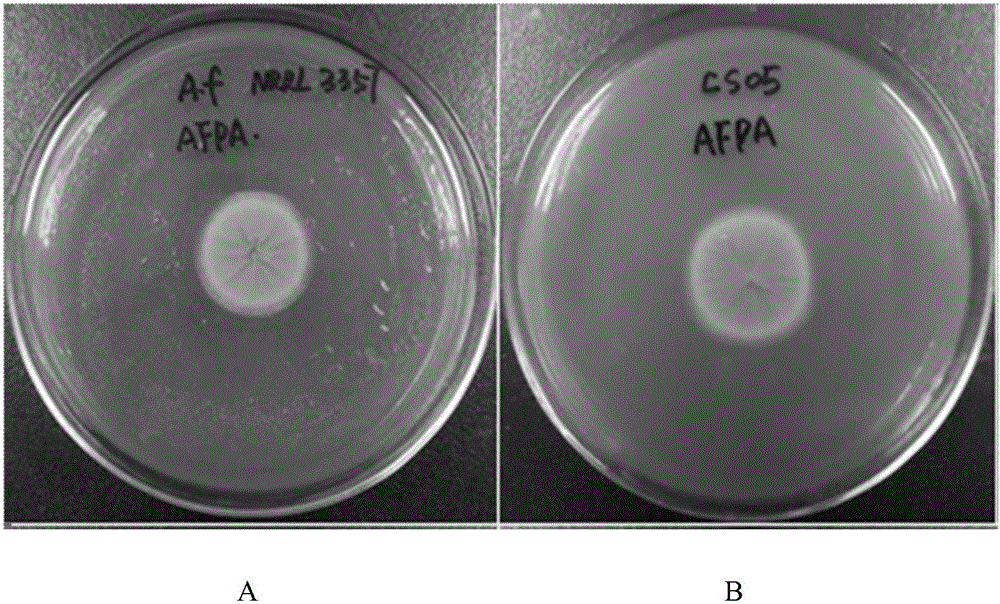

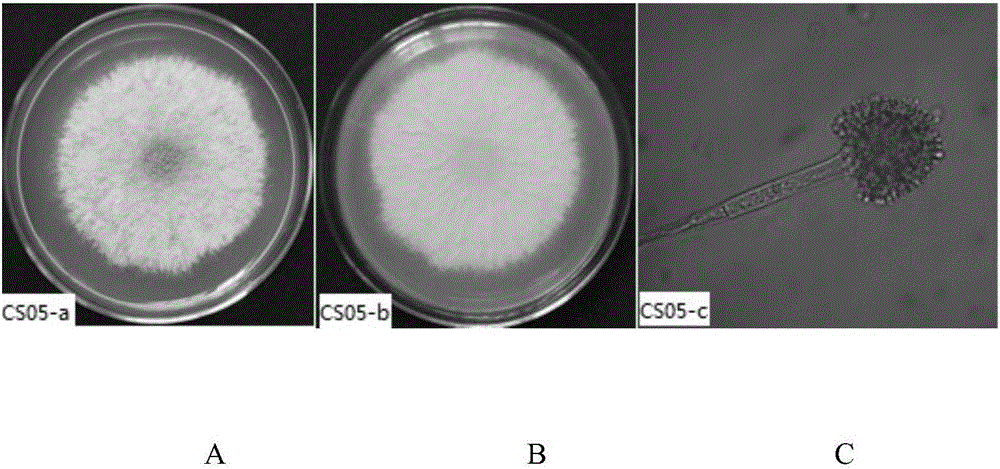

[0020] Isolation, purification, identification of embodiment 1 Aspergillus flavus CS05

[0021] 1. Isolation and purification of strains

[0022] The method refers to "Identification of Common Toxigenic Molds in Microbiological Examination of Food Hygiene" (GB / T 4789.16-2003) and "Standard Atlas of Fungi for Grain and Oil Inspection and Stored Grain Part 1: Aspergillus" (GB / T 26628.1-2011). Use the dilution separation method to isolate the mold in the sample, and then use the mycelia tip picking method or spot planting method to purify the obtained strains, number them and save them for future use. Cottonseed samples were pulverized and prepared into a spore suspension. After dilution, the appropriate dilution suspension was selected and inoculated into Chapeauer's agar medium by coating method, and cultured continuously at 28°C for 5-7 days. In order to separate the target mold from other molds and bacteria, further isolation and purification are required. When the mold gro...

Embodiment 2

[0038] The toxin-producing ability analysis of embodiment 2 Aspergillus flavus CS05

[0039] Inoculate 2uL of spore suspension in the center of potato dextrose agar (PDA) medium (25mL), culture upside down at 30°C for 7 days, and measure AFB by high performance liquid chromatography 1 content. Accurately weigh 20 g (accurate to 0.01 g) of the prepared samples (corn, wheat, soybean, soybean meal, cottonseed and cotton meal), put them into a series of 150 mL Erlenmeyer flasks, and autoclave at 121 °C for 20 min. Weigh non-sterile samples in the same manner. Inoculate the spore suspension of Aspergillus flavus in the Erlenmeyer flask containing the sample in the aseptic operating table to ensure that the final spore concentration is 10 6 pcs / g. The water content of the sample was adjusted to 18% with sterile physiological water. Fully mix the sample in each Erlenmeyer flask with a sterile glass rod, so that the Aspergillus flavus spore suspension is evenly distributed and sea...

Embodiment 3

[0050] Comparison of the toxin-producing ability of embodiment 3 Aspergillus flavus CS05 and standard toxin-producing strain NRRL3357

[0051] Aspergillus flavus CS05 and standard toxin-producing bacterial strain NRRL3357 were inoculated into pulverized corn, wheat, soybean, soybean meal, cottonseed and cotton meal respectively by the method in above-mentioned embodiment 2, after cultivating 10d in the constant temperature and humidity incubator, yellow yellow AFB of Aspergillus CS05 in the above-mentioned feed ingredients and by-products 1 The yields were 11.313mg / kg, 0.025mg / kg, 0.461mg / kg, 0.024mg / kg, 0.089mg / kg, 0.021mg / kg, all higher than the AFB of the standard toxin-producing strain NRRL3357 1 Yield (1.528 mg / kg, 0.004 mg / kg, 0.094 mg / kg, 0.018 mg / kg, 0.008 mg / kg, 0.008 mg / kg).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com