3D graphene/one-dimensional nanomaterial composite structure field emission cathode and preparation method

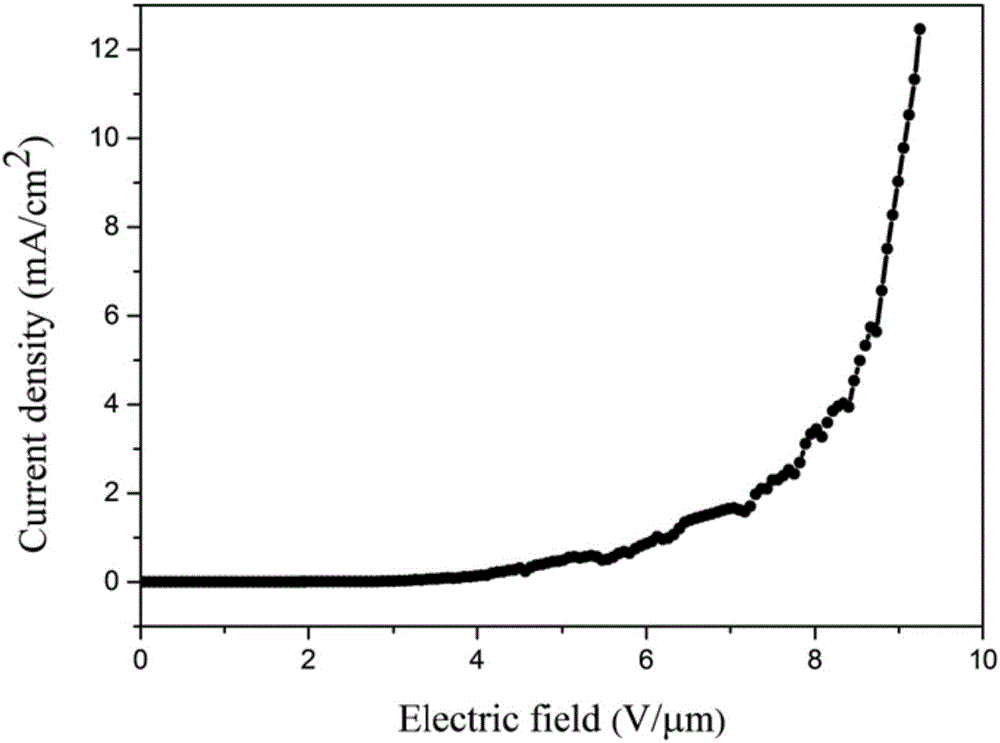

A field emission cathode and nanomaterial technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problem of insufficient utilization of graphene performance, and achieve good application prospects and low turn-on electric field. , the effect of increasing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of the above-mentioned 3D graphene / one-dimensional nanomaterial composite structure field emission cathode, comprising the following steps:

[0032] Step 1. Wash the metal foam with a traditional substrate cleaning process, and dry it with nitrogen for later use;

[0033] Step 2, growing graphene on the metal foam after step 1 treatment;

[0034] Step 3, using a deposition method to deposit a one-dimensional nanomaterial seed layer on the substrate with graphene grown after the treatment in step 2;

[0035] Step 4, growing one-dimensional nanomaterials on the substrate treated in Step 3.

[0036] The one-dimensional nanomaterial seed layer is a material seed layer that the one-dimensional nanomaterial has good field emission performance, and ZnO, ZnS, ZnSe, SiC, CuO, MoO can be selected. 2 or AlN with a total thickness of 10-20nm.

[0037] The metal foam cleaning process in step 1 is as follows: first soak in dilute hydrochloric acid for 5-10 min...

Embodiment

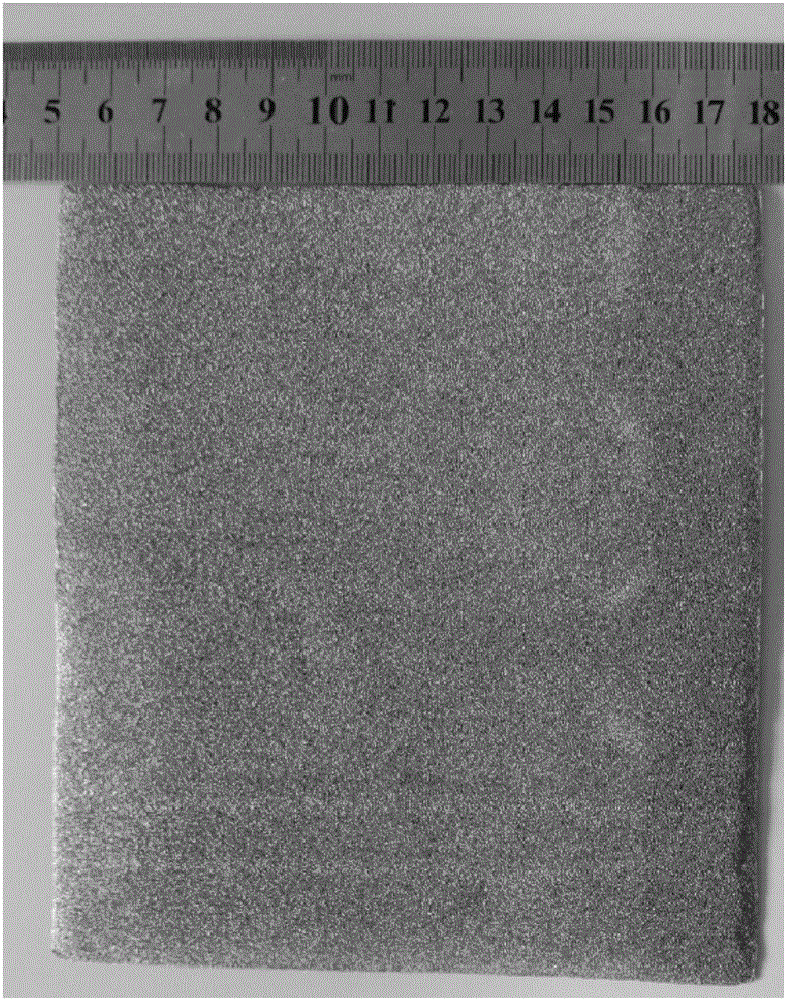

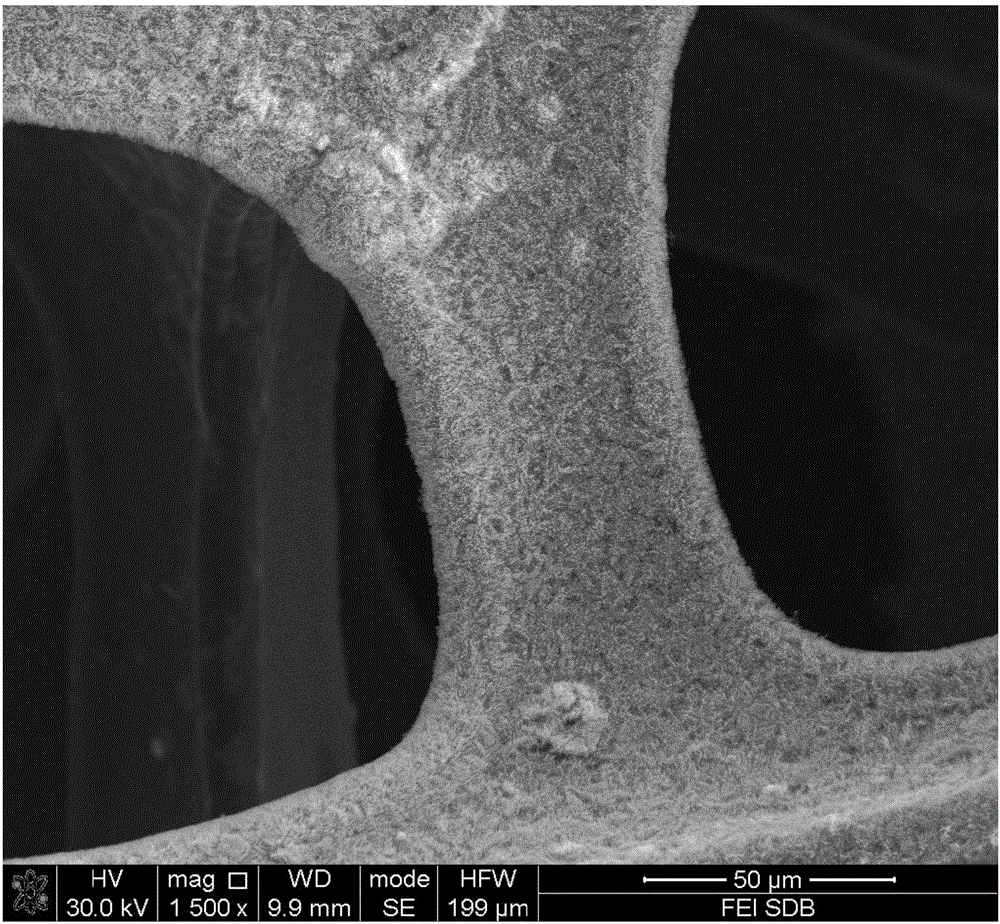

[0039] Cut metal Ni foam 12×10cm (length×width) and clean it, first soak it with dilute hydrochloric acid for 5-10 minutes, then alternately ultrasonicate it with ethanol, acetone, and isopropanol for 10-60 minutes, and blow dry it with nitrogen for later use; put the cleaned metal Ni The foam is placed in a CVD tube furnace to grow 3D graphene; the temperature of the furnace is raised to 930°C, and Ar:H 2 =250: 100sccm annealed for 5 minutes, then 5sccm CH 4 5min; Deposit a zinc oxide seed layer on the grown graphene by atomic layer deposition (ALD), with a deposition thickness of 10-20nm; put the 3D graphene substrate deposited with the zinc oxide seed layer into a zinc oxide growth Zinc oxide nanorod arrays were grown by hydrothermal method in a liquid reaction kettle, the temperature was 90°C, and the time was 3-6h; the growth solution of zinc oxide nanorods was Zn(NO3)2•6H2O (50mM) and hexamethylenetetraammonium ( HMTA, 50mM) mixed solution; finally 80 ℃ vacuum drying fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com