Thin film prepared from inorganic mineral powder

A technology of inorganic mineral powder and film, which is applied in the direction of film/flaky adhesives and adhesives, which can solve the problems of poor environmental performance and high cost of tapes, and achieve the effects of low cost, reduced raw material cost, and high elastic recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

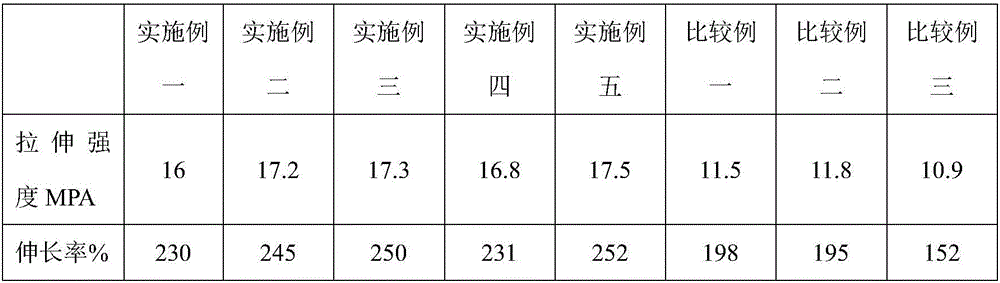

Examples

Embodiment 1

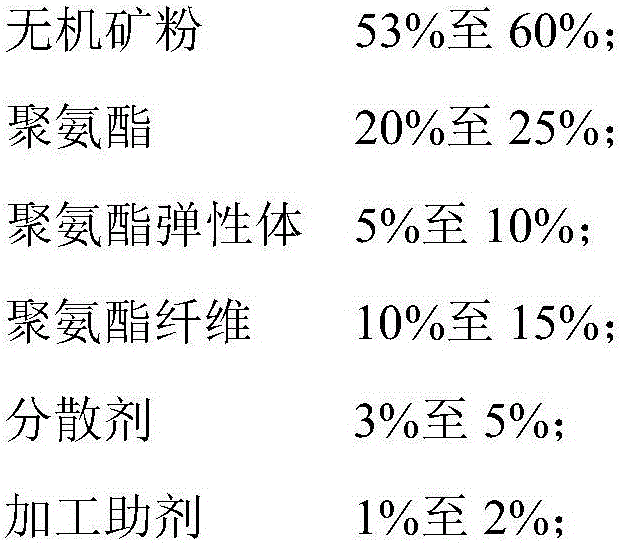

[0045] Step A: weigh the raw materials according to the raw material formula ratio, successively add 55% by weight of inorganic mineral powder, 20% by weight of polyurethane, 5% by weight of polyurethane elastomer, 15% by weight of polyurethane fiber, 3% by weight of dispersant and The processing aid of 2% by weight is added in the mixer, mixed for 8 minutes, and the mixer rotating speed is 80r / min;

[0046] The processing aid is: methyl methacrylate copolymer. Wherein said dispersant is: polyethylene wax. The inorganic mineral powder is: calcium carbonate. The particle size of the calcium carbonate is 3000 mesh. The length of the polyurethane fiber is 30 to 50 mm.

[0047] Step B: granulation: the mixed material obtained in step A is then fed into a screw extruder, melted and kneaded at a temperature of 150° C., and made into a granular material;

[0048] Step C: Put the granular material into the extruder with the extruder and the O-shaped die forming mechanism, control ...

Embodiment 2

[0052] Step A: weigh the raw materials according to the raw material formula ratio, successively add 56% by weight of inorganic mineral powder, 22% by weight of polyurethane, 7% by weight of polyurethane elastomer, 10% by weight of polyurethane fiber, 4% by weight of dispersant and The processing aid of 1% by weight is added in the mixer, mixed for 10 minutes, and the mixer speed is 80r / min;

[0053] The processing aid is: methyl methacrylate copolymer. Wherein said dispersant is: polyethylene wax. The inorganic mineral powder is: calcium carbonate. The particle size of the calcium carbonate is 3000 mesh. The length of the polyurethane fiber is 30 to 50 mm.

[0054] Step B: granulation: the mixed material obtained in step A is then fed into a screw extruder, melted and kneaded at a temperature of 160°C, and made into a granular material;

[0055] Step C: Put the granular material into the extruder with the extruder and the O-shaped die forming mechanism, control the temper...

Embodiment 3

[0058] Step A: weigh the raw materials according to the raw material formula ratio, successively add 53% by weight of inorganic mineral powder, 25% by weight of polyurethane, 5% by weight of polyurethane elastomer, 11% by weight of polyurethane fiber, 5% by weight of dispersant and The processing aid of 1% by weight is added in the mixer, mixed for 9 minutes, and the mixer speed is 80r / min;

[0059] The processing aid is: methyl methacrylate copolymer. Wherein said dispersant is: polyethylene wax. The inorganic mineral powder is: calcium carbonate. The particle size of the calcium carbonate is 3000 mesh. The length of the polyurethane fiber is 50 mm.

[0060] Step B: granulation: the mixed material obtained in step A is then fed into a screw extruder, melted and kneaded at a temperature of 170° C., and made into a granular material;

[0061] Step C: Put the granular material into the extruder with the extruder and the O-shaped die forming mechanism, control the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com