High-transparency high-heat-insulation thermal phase change material preparation method

A technology of transparency and heat insulation, applied in chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve the problem of poor light transmission, high transparency and high heat insulation, and no phase change characteristics. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

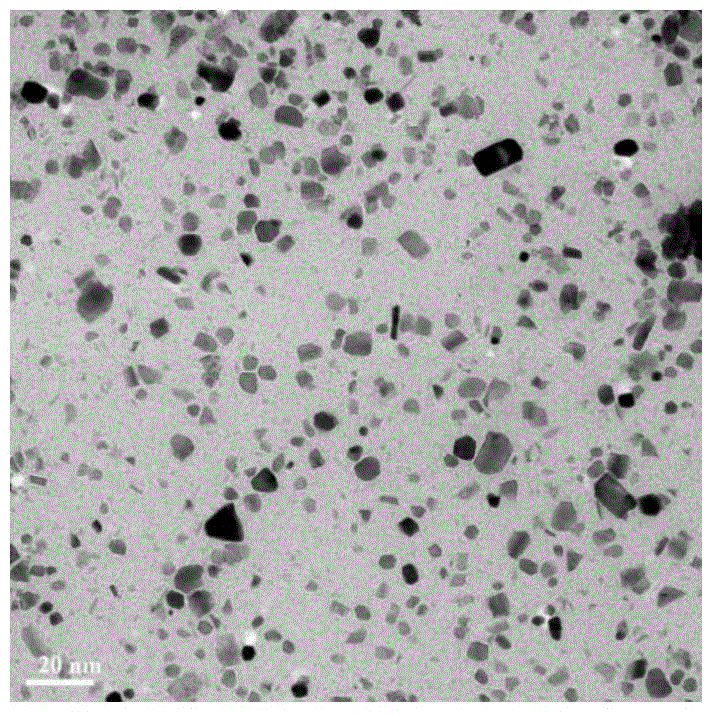

[0052] First prepare VO with a particle size not greater than 20nm 2 (Phase B) solution: put in a 10L high temperature and high pressure reaction kettle accordingly, ①6kg of zirconia balls with a diameter of 0.1mm, ②200g of vanadyl isopropoxide, ③4g of phosphotungstic acid, ④Mix methanol and purified water Solvent: 3788g, ⑤ dispersant: phosphoric acid 4g, ⑥ reducing agent: triethanolamine 4g, cover the lid, start heating and pressurizing, high-speed rotating reactor stirring rotor, temperature setting is 260 degrees, pressure setting is 15kg, speed setting Set as 6000 rev / min, the reaction dispersion time is set as 24 hours. After 24 hours of reaction, grinding and dispersion, the primary particle size of VO is not greater than 20nm 2 (Phase B) Precursor solution, such as figure 1 shown.

[0053] Then take the VO obtained above 2 (Phase B) The solution was freeze-dried to obtain VO 2 (Phase B) nano powder, referred to as: V powder.

[0054] Preparation of precursors of h...

Embodiment 2

[0079] First prepare VO with a particle size not greater than 20nm 2 (Phase B) solution: put into a 10L high-temperature and high-pressure reactor according to this, ①5kg of zirconia balls with a diameter of 0.1mm, ②400g of vanadyl isopropoxide, ③12g of sodium phosphotungstate; ④Methanol and purified water Mixed solvent 3564g, ⑤ dispersant: phosphoric acid 12g, ⑥ reducing agent: triethanolamine 12g, cover the lid, start heating and pressurizing, high-speed rotating reactor stirring rotor, the temperature is set to 260 degrees, the pressure is set to 15kg, the speed is set to Set as 6000 rev / min, the reaction dispersion time is set as 24 hours. After 24 hours of reaction, grinding and dispersion, the primary particle size of VO is not greater than 20nm 2 (Phase B) Precursor solution.

[0080] Then the VO2 (phase B) solution obtained above was freeze-dried to obtain VO 2 (Phase B) nano powder, referred to as: V powder.

[0081] Preparation of precursors of high thermal insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com